Engine control system

A technology for engine and engine temperature, applied in road vehicle drive control systems, engine components, machines/engines, etc., can solve problems such as increased power consumption of coolant pumps, lowering of cylinder heads, and deterioration of boiling coolants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

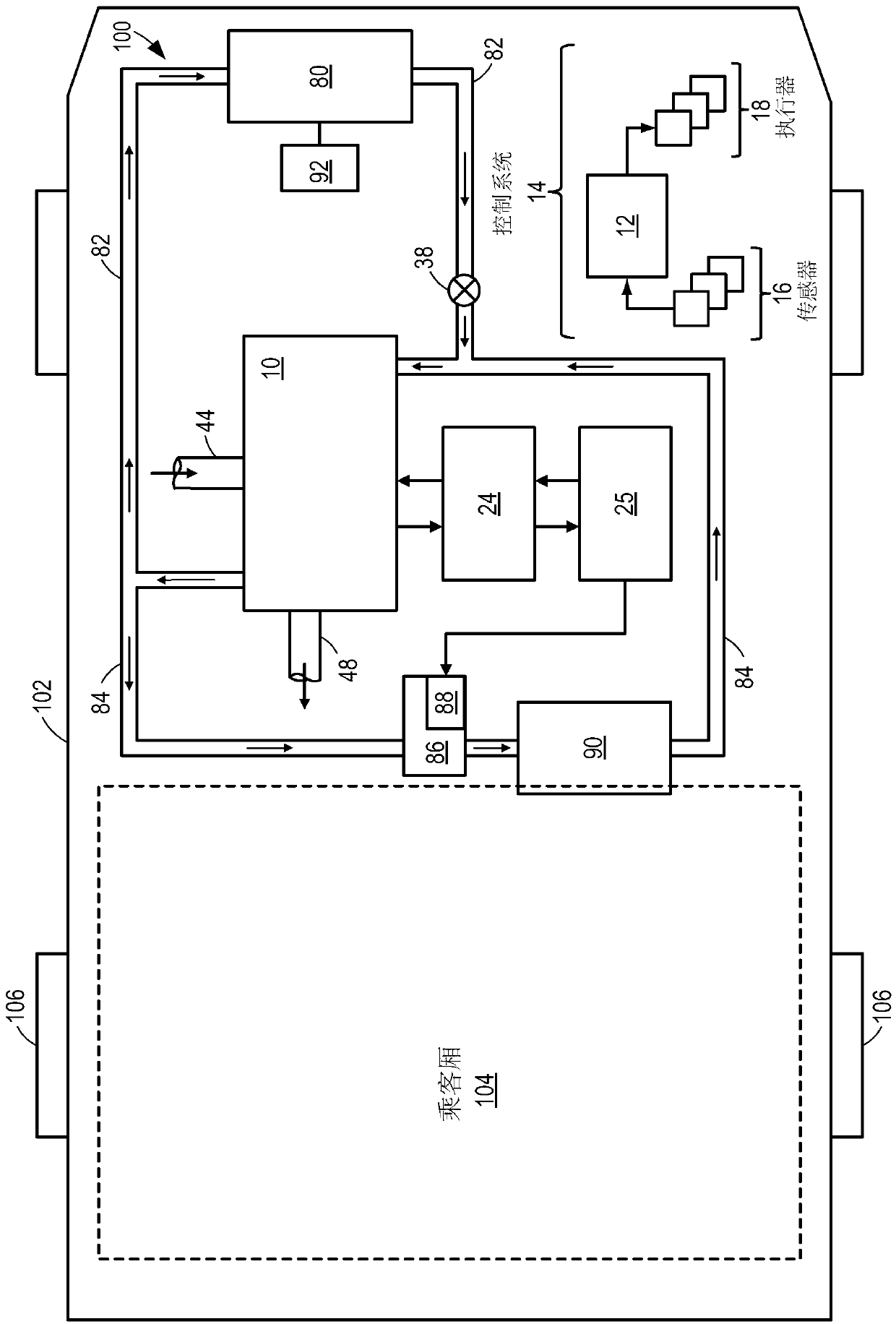

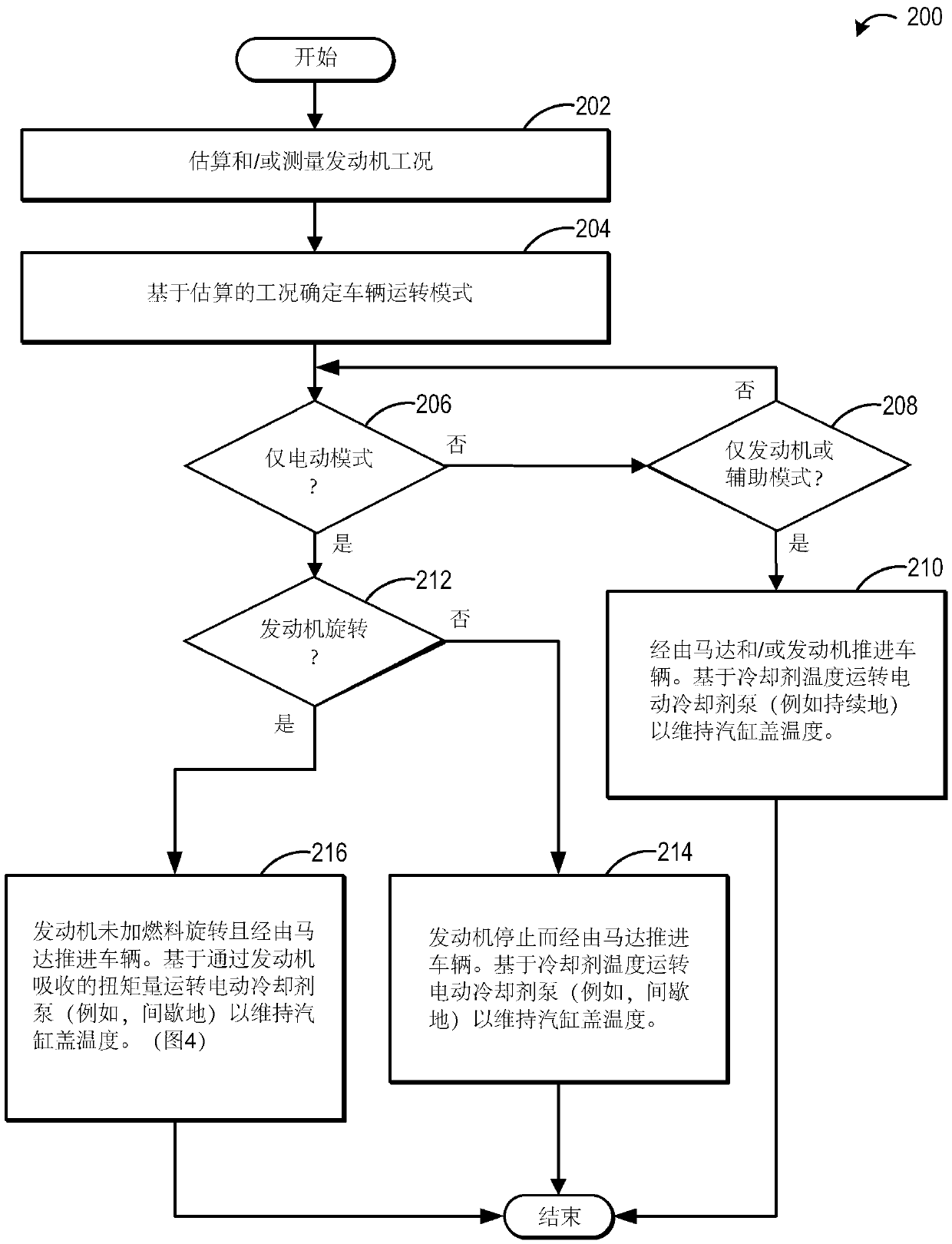

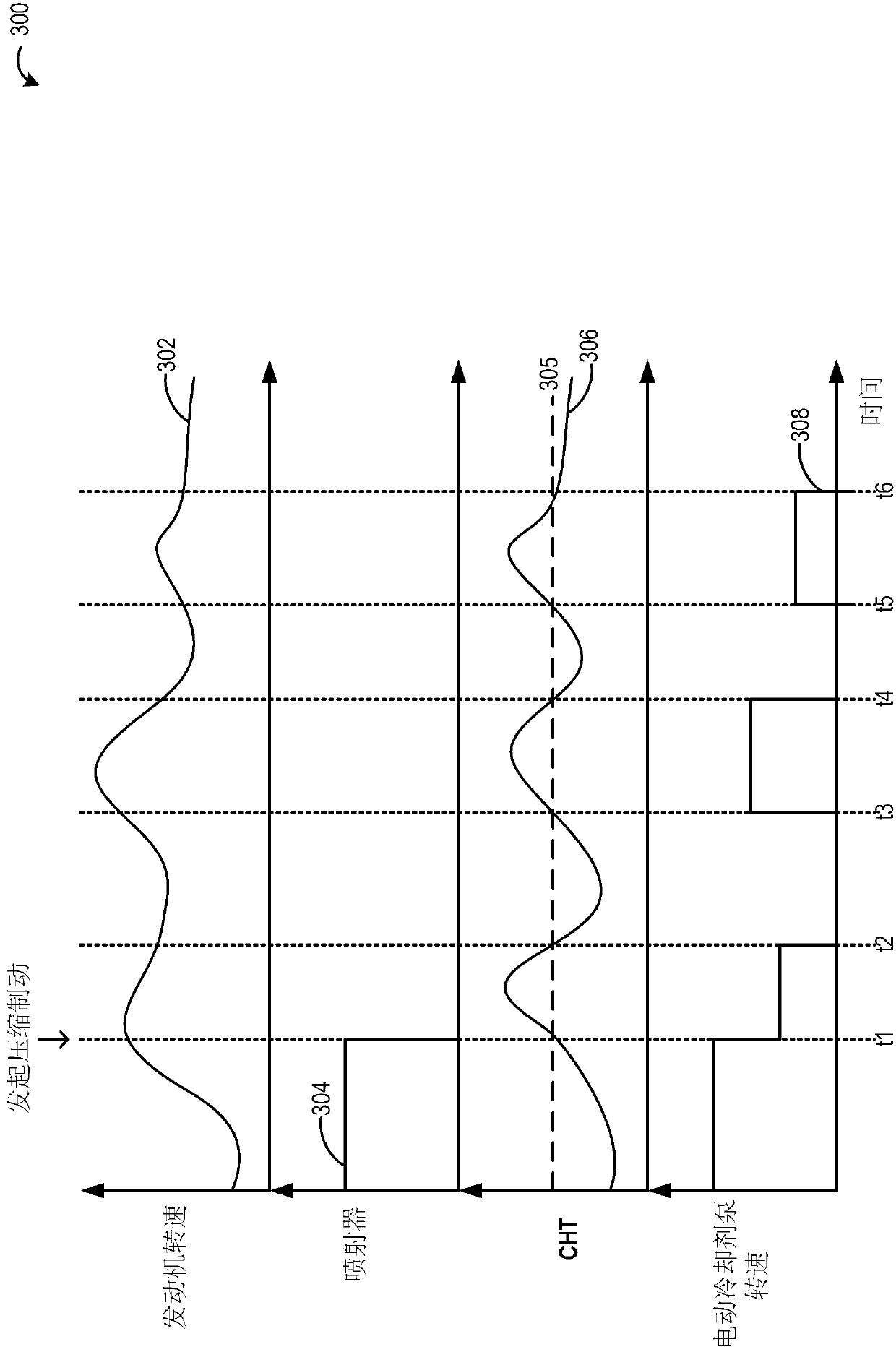

[0012] The instructions below relate to adjusting the auxiliary engine coolant pump based on the amount of engine compression braking torque (e.g. figure 1 A method and system for the operation of a coolant pump). During conditions when the vehicle is propelled by the motor and the engine is spinning without fuel, heat generated by the engine due to torque absorption may be dissipated by operating the engine coolant pump. The controller can be configured to execute control programs such as figure 2 Example method of ) to operate the engine coolant pump based on vehicle speed and compression braking torque in order to maintain engine temperature below a threshold. reference here image 3 Operation of an example coolant pump is described. In this way, the temperature of the engine can be maintained even during compression braking without reducing the efficiency of the coolant pump.

[0013] now go to figure 1 , schematically illustrates an example embodiment of a cooling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com