Novel blade spring of machine tool

A leaf spring and machine tool technology, applied in the field of mechanical parts, can solve the problems of reducing elasticity, large friction between multi-leaf spring plates, large quality and volume, etc., and achieve the effect of high tensile strength and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

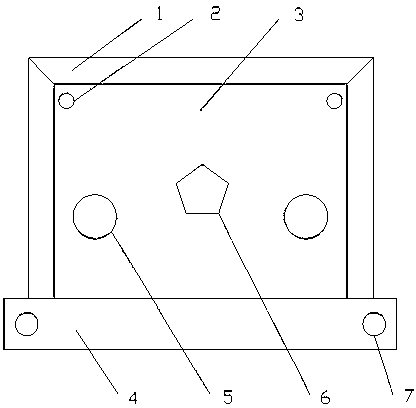

[0012] See figure 1 , A new type of plate spring for machine tools, comprising: multiple spring groups 5, multiple steel plates 3, connecting holes 2, fixed struts 4, multiple connecting struts 1 and balance weights 6, the three steel plates 3 are superimposed and combined The steel plate 3 is arranged into a whole body, the bottom of the steel plate 3 is connected with two spring groups 5 by screws, the steel plate 3 is provided with connecting holes 2 on four sides, and the three steel plates 3 are connected to each other by four connecting struts 1. A balance weight 6 is installed inside the steel plate 3, and the fixed support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com