A system and method for seabed storage of high-pressure gas

A high-pressure gas and gas pressure technology, which is applied in the method of container discharge, container filling method, fixed-capacity gas storage tank, etc., can solve the problems of unsafe, occupying land resources, increasing costs, etc., and achieves alleviation of land tension and safety. The effect of high coefficient and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

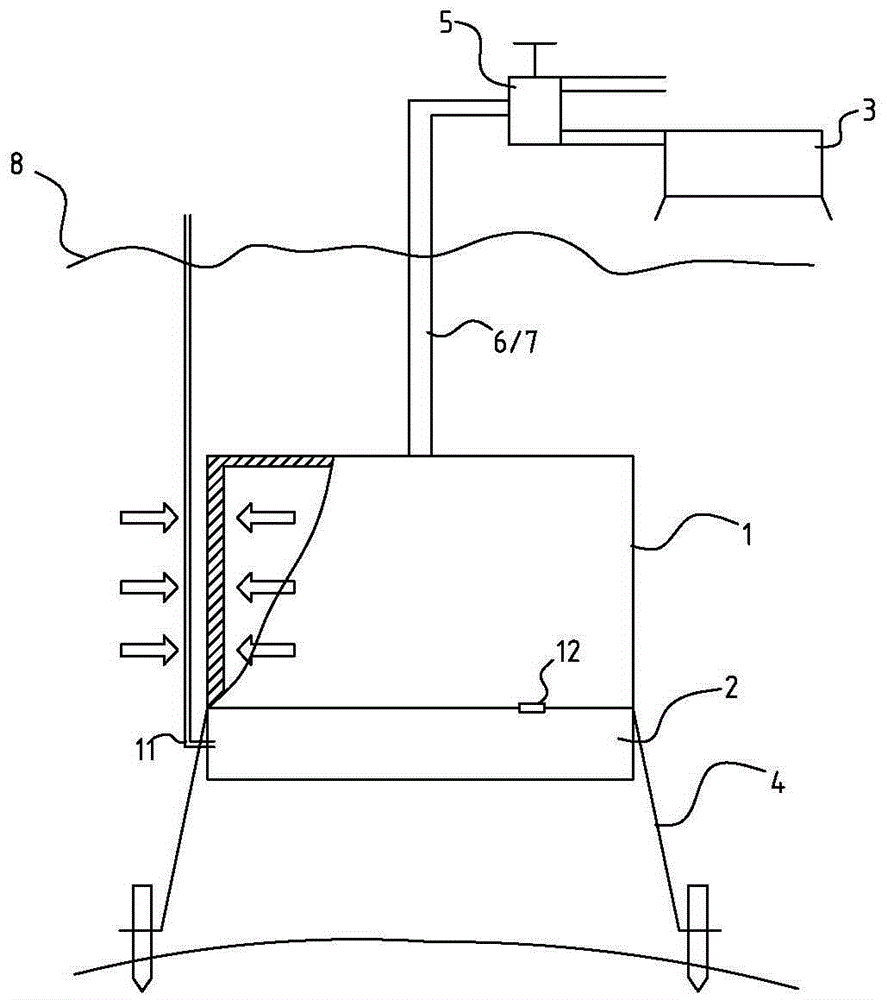

[0021] Such as figure 1 As shown, a system for storing high-pressure gas on the seabed includes a closed gas tank 1 disposed on the seabed below sea level 8, a gas compressor 3 disposed on land, and a lifting device that drives the closed gas tank 1 to float in the seabed. The airtight gas tank 1 is provided with an intake pipe 6 and an exhaust pipe 7, and the gas compressor 3 compresses the high-pressure gas into the airtight gas tank 1 through the air intake pipe 6, and the airtight gas tank 1 is exhausted through the airtight gas tank 1. The pipe 7 releases high-pressure gas to the outside. In this embodiment, the inlet pipe 6 and the exhaust pipe 7 are integrated into one pipe through the valve 5, and the functions of air intake and exhaust are realized through the control of the valve 5. The airtight gas tank 1 is provided with a gas pressure sensor (not marked), and the gas pressure sensor is responsible for collecting the pressure value in the airtight gas tank 1; the a...

Embodiment 2

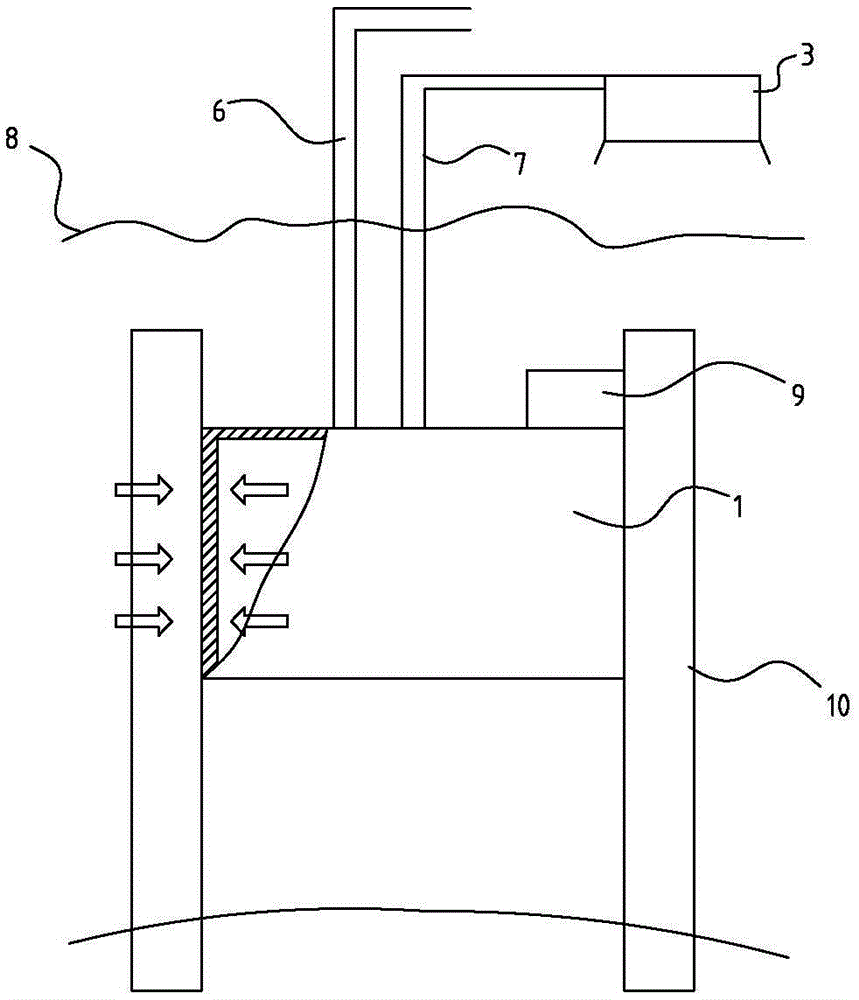

[0024] Such as figure 2As shown, a system for storing high-pressure gas on the seabed includes a closed gas tank 1 arranged on the seabed below the sea level, a gas compressor 3 arranged on land, and a lifting device for driving the closed gas tank 1 to float in the seabed. The airtight gas tank 1 is provided with an intake pipe 6 and an exhaust pipe 7, and the gas compressor 3 compresses the high-pressure gas into the airtight gas tank 1 through the air intake pipe 6, and the airtight gas tank 1 is exhausted through the airtight gas tank 1. Pipe 7 releases high-pressure gas outward. The airtight gas tank 1 is provided with a gas pressure sensor (not marked), and the gas pressure sensor is responsible for collecting the pressure value in the airtight gas tank 1; the airtight gas tank 1 is provided with a liquid pressure sensor, and the liquid pressure sensor is responsible for collecting The pressure value outside the airtight gas tank 1; the data collected by the gas pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com