Double cold source water-cooled heat pipe energy-saving refrigerating system

A refrigeration system, water-cooled technology, which is applied in the field of energy-saving refrigeration systems with double-cooled water-cooled heat pipes. It can solve the problems of affecting the cooling capacity of the equipment, the distance cannot be too long, and the installation conditions are limited, so as to achieve simple structure, save electricity costs, and improve energy efficiency. than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

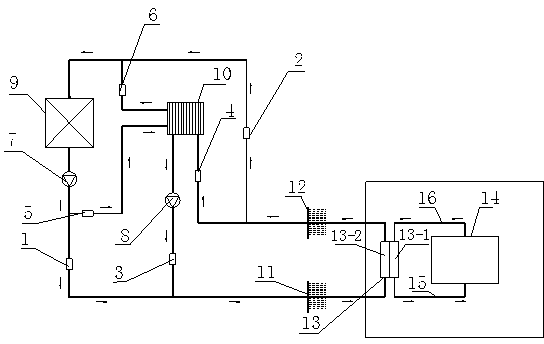

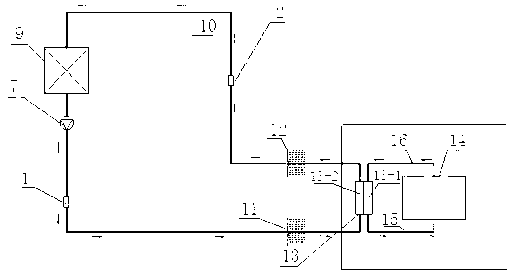

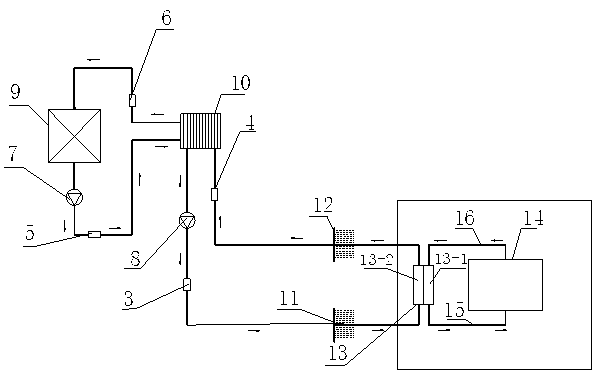

[0025] The double cold source water-cooled heat pipe energy-saving refrigeration system, the refrigeration system includes a heat exchange device, a cooling device and a water pump, and the heat exchange device, cooling device and water pump are connected to each other through pipelines to form a cycle.

Embodiment 2

[0027] As an improvement of the present invention, the cooling device is configured as a double cooling source cooling device, including a first cooling source and a second cooling source, and the first cooling source and the second cooling source are connected through pipes and valves . The rest of the structures and advantages are the same as in Embodiment 1.

Embodiment 3

[0029] As an improvement of the present invention, the first cold source includes a cooling tower 9, the cooling tower 9 is connected to the heat exchange device through the connection pump 7, the electric valve 1, and the cooling tower 9 uses a natural cold source to cool the cooling return water . The rest of the structures and advantages are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com