Sliding bearing having improved lubrication characteristics

A technology of sliding bearings and sintered alloys, which is applied to bearings, bearing components, shafts and bearings, etc., can solve the problems of weak improvement effect of lubrication characteristics, small effect, reduction of lubricating oil impregnation rate, etc., and achieve excellent durability and lubrication characteristics Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-7

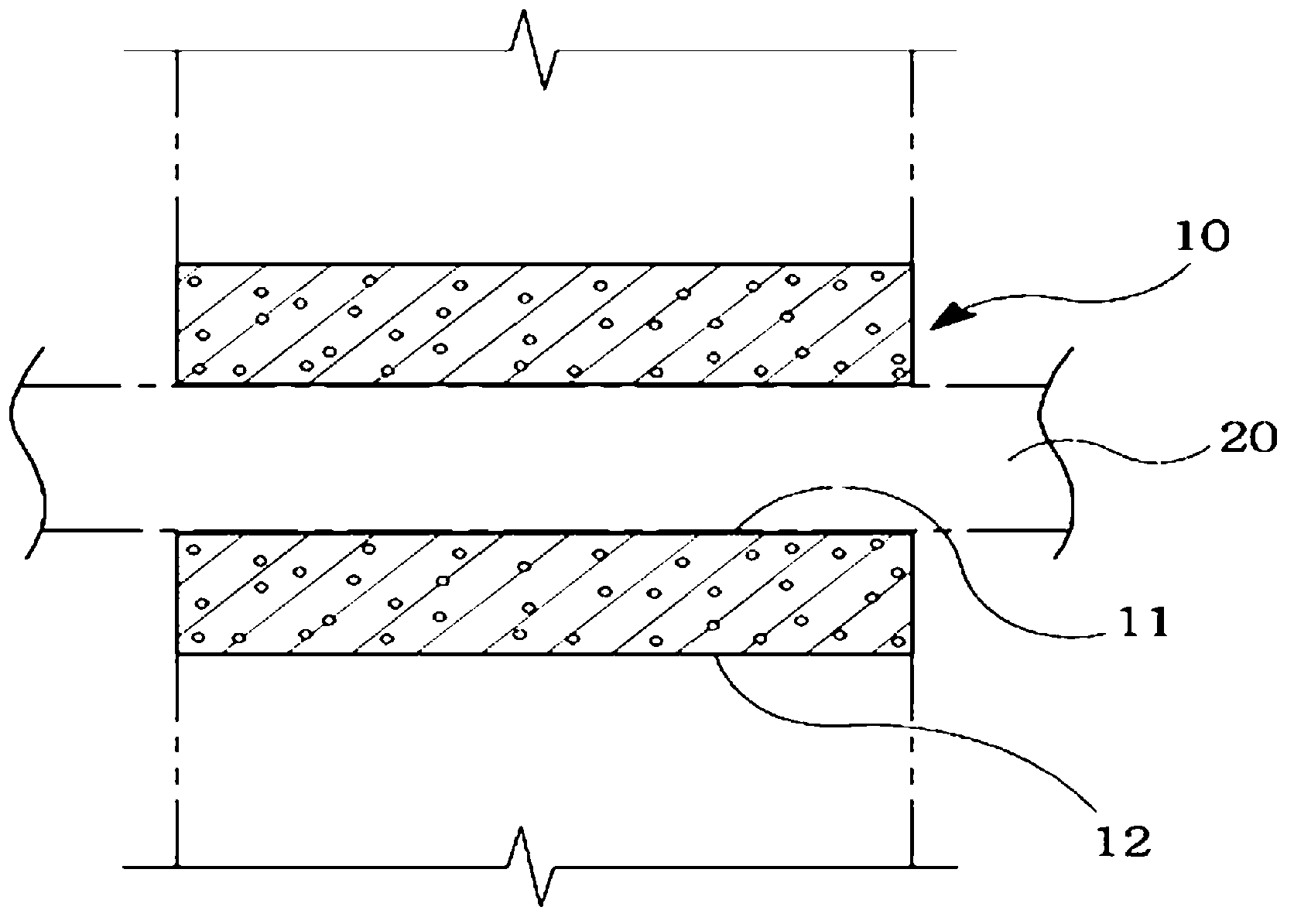

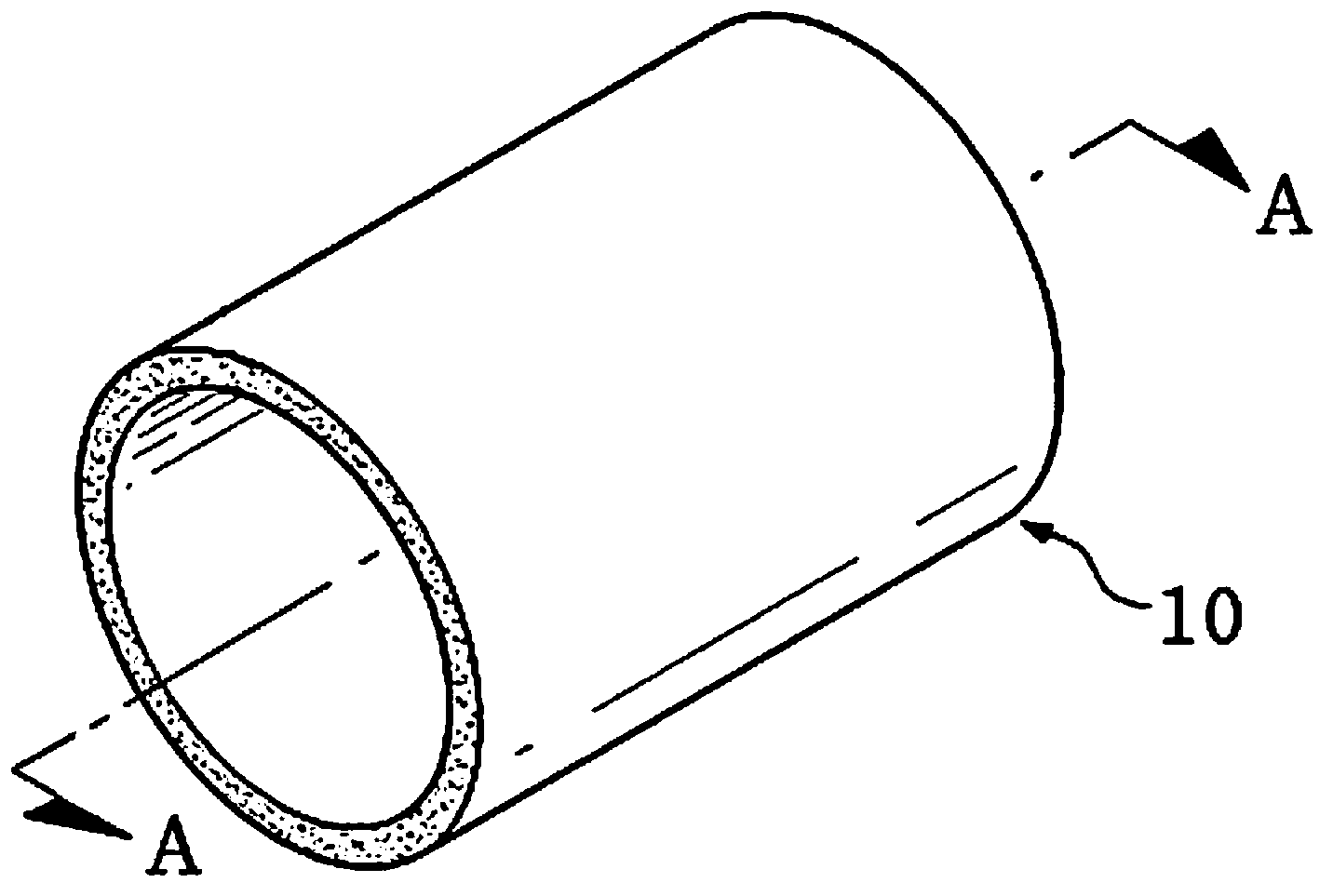

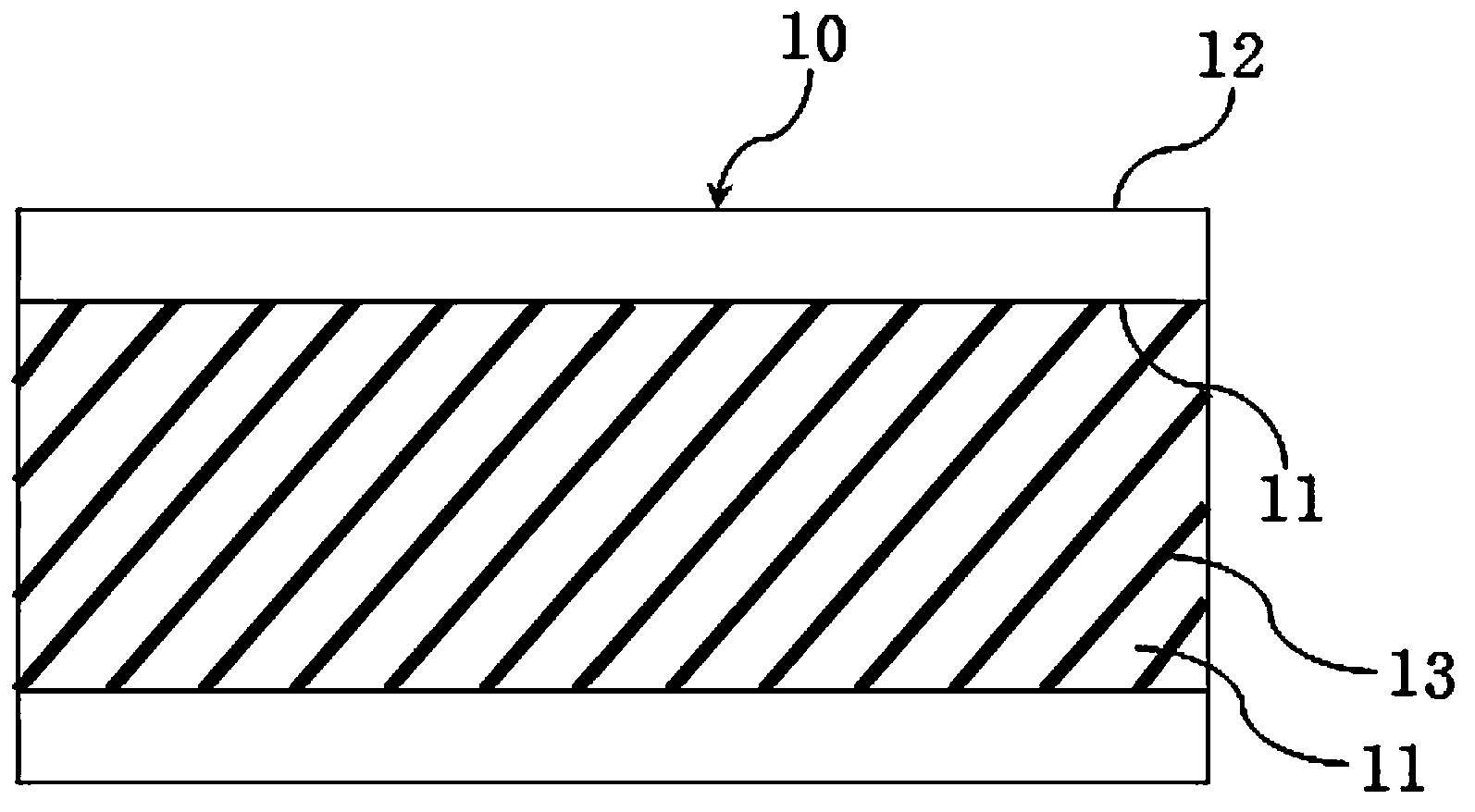

[0077] Manufacture of sliding bearings

[0078] According to the composition described in the following Table 1, prepare the composition powder for sliding bearings, use stearic acid series lubricants to mix these powders, and then use 3,000kg / cm 2 The pressure is pressurized to produce a molded body in the form of an annular sleeve.

[0079] Commercially available powders of the components listed in Table 1 were used. For example, the iron powder uses the powder of Hoeganaes Company, copper and copper-tin alloy (Cu30Sn; copper-tin alloy containing 30 wt% tin) is the powder of Korea Changxing Company, C is a commercially available graphite product, Ni and B are The B-Ni product of Hoeganaes Company, Mo, W, and Mn are tool steel powders.

[0080] As Comparative Examples 1 and 2, sliding bearings were produced with the same component contents as in Example 1. Comparative Examples 1 and 2 differ from Examples in the formation of unevenness.

[0081] Table 1

[0082] Example...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap