Lathe and screw rod support device thereof

A support device and screw technology, applied in feeding devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of reduced processing accuracy, screw failure, screw deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

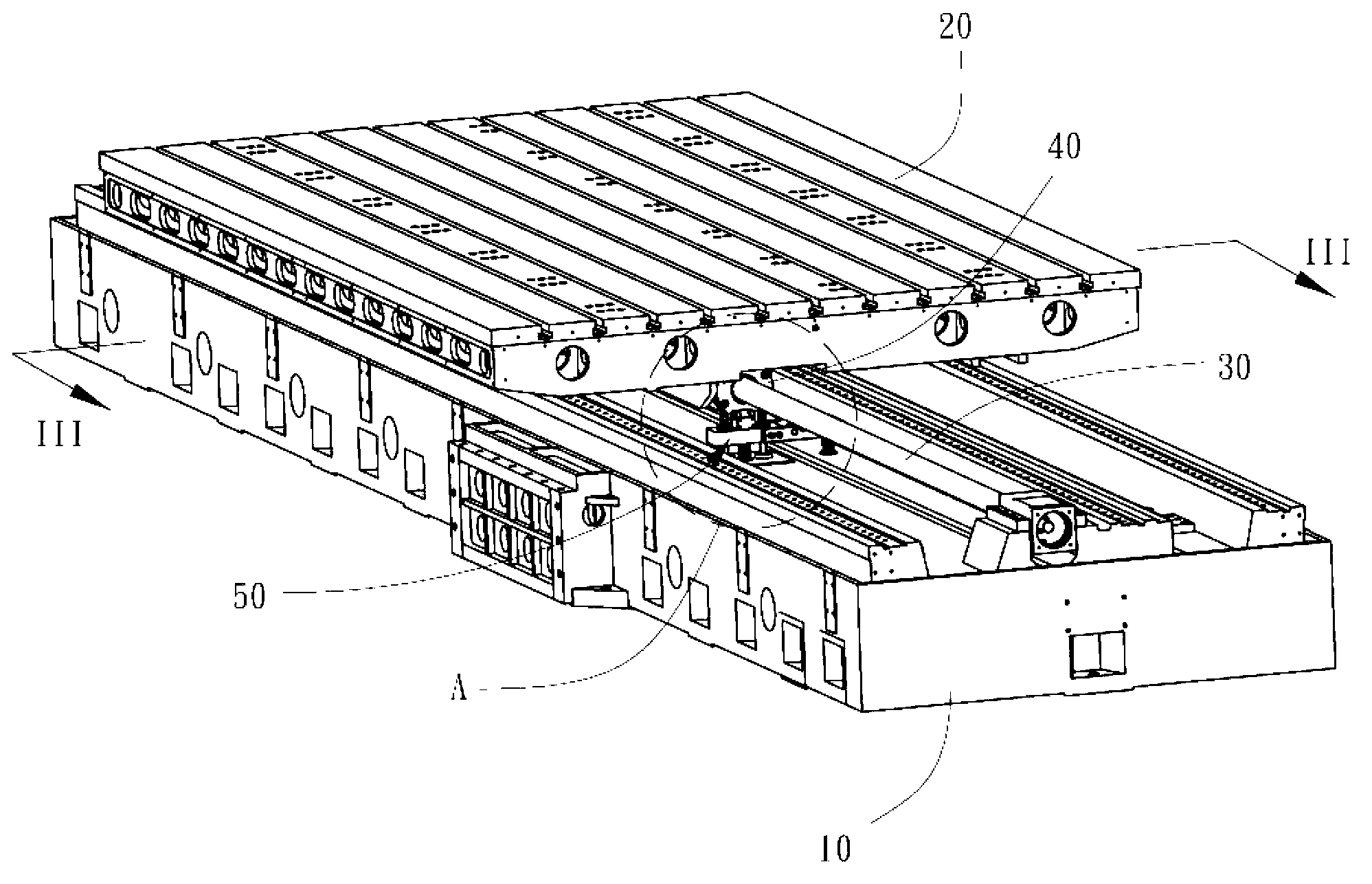

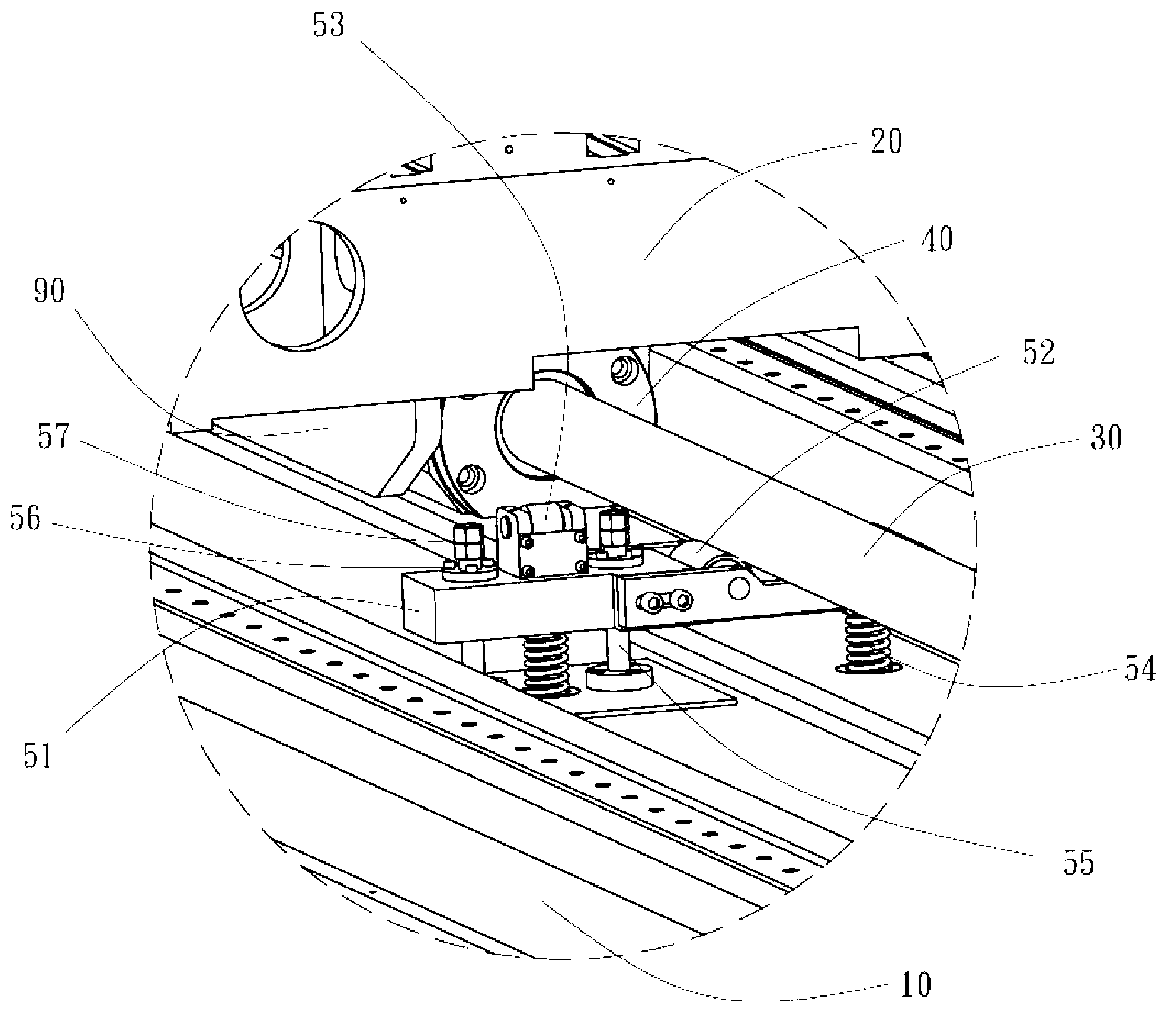

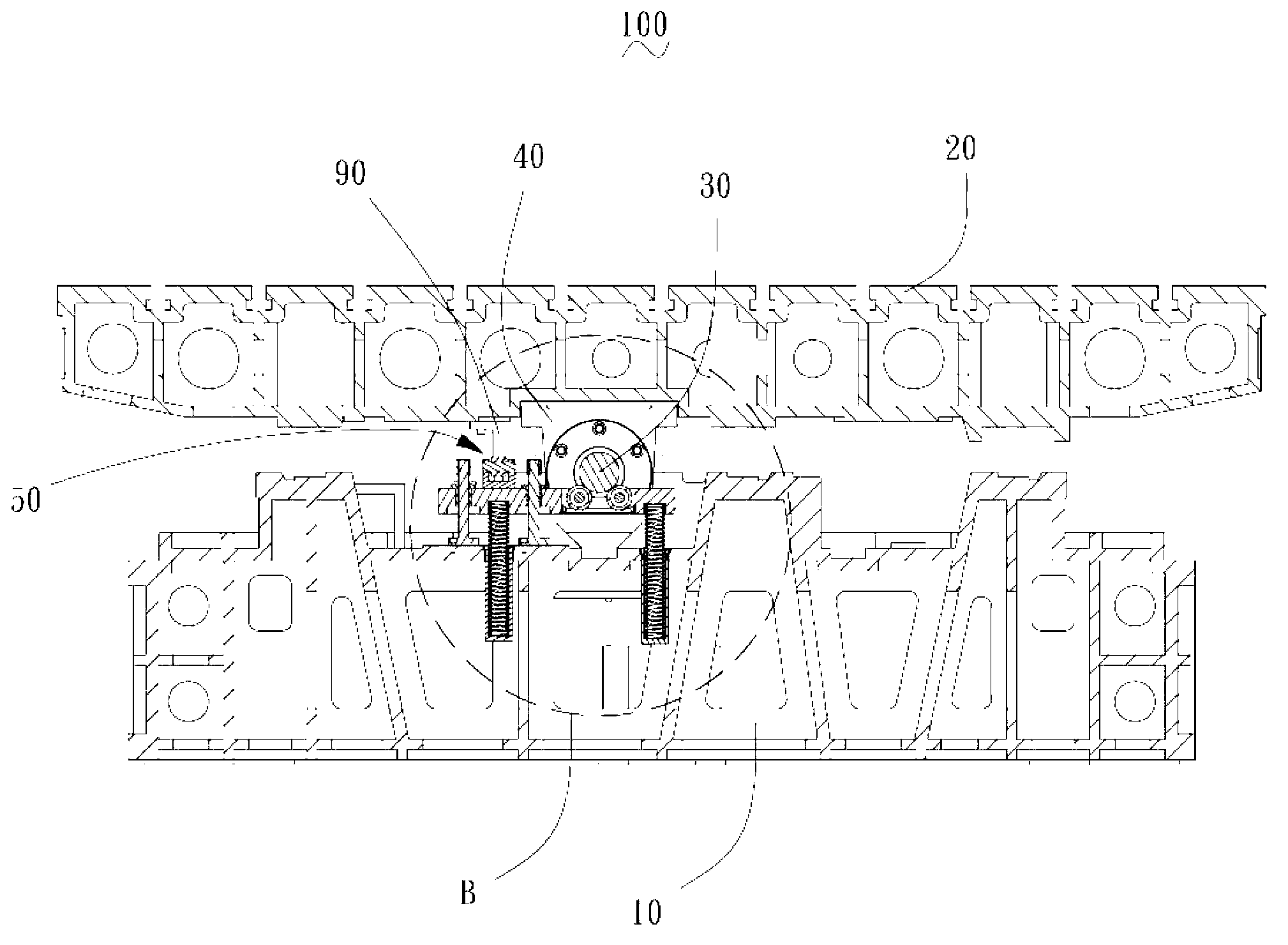

[0021] Such as figure 1 and figure 2 Shown is a machine tool 100 of a preferred embodiment of the present invention, and the machine tool 100 is a numerically controlled machine tool in this embodiment. The machine tool 100 includes a base 10 and a workbench 20 . The base 10 is equipped with a driving motor (not shown) and a screw 30 connected to the driving motor at one end, and the other end of the screw 30 is fixed on the base 10 through a bearing seat (not shown). A nut 40 mounted on the screw 30 is fixed at the bottom of the workbench 20 . When the screw 30 rotates, the nut 40 is driven to drive the workbench 20 to move back and forth along the axis of the screw 30 . The base 10 is further provided with a screw supporting device 50 , and the screw supporting device 50 elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com