beam tank

A beam-type and tank-container technology, which is applied in the field of tank containers, can solve the problems of not being able to make full use of the strength of the frame corner columns and the unreasonable stress state of the upper and lower supports, and achieve the effects of reasonable stress state, shortened length, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

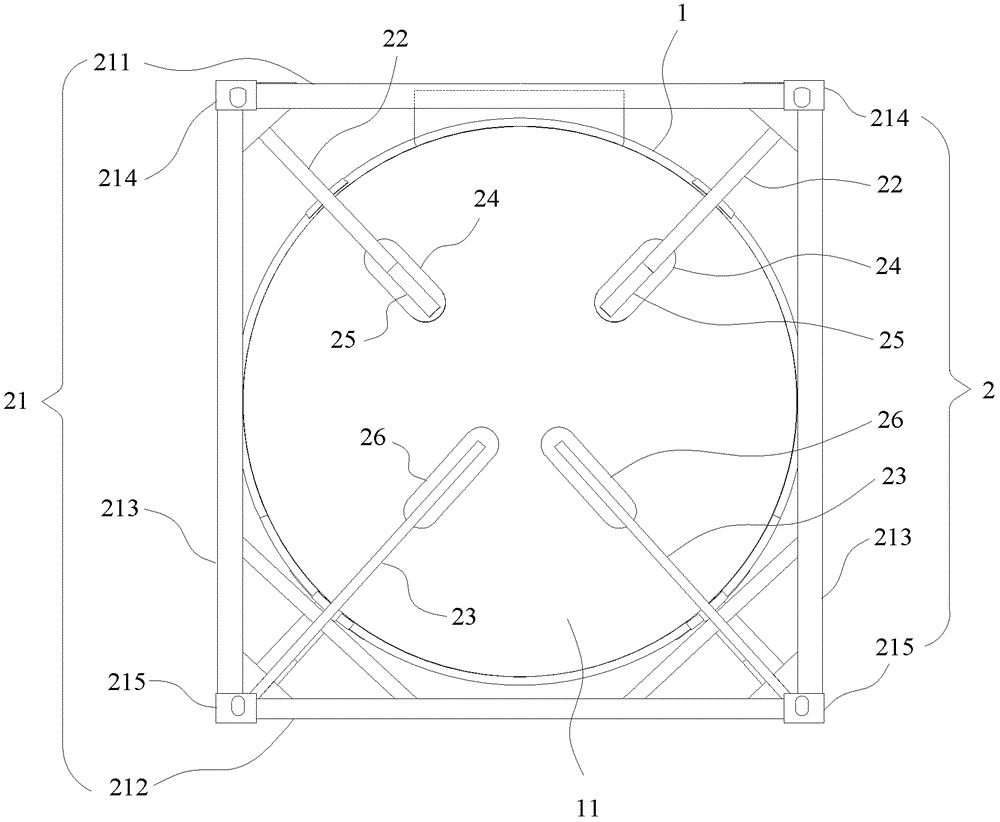

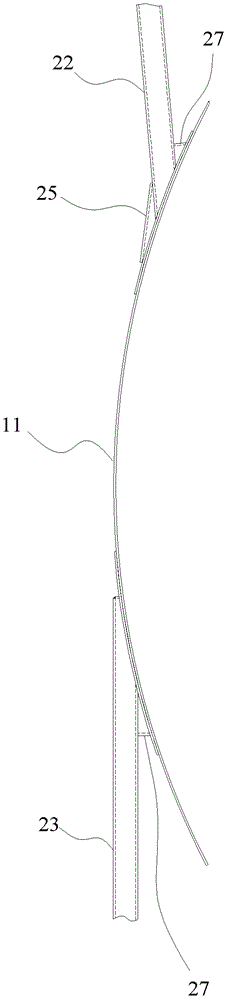

[0018] see Figure 1 to Figure 2 As shown, the beam-type tank of the present invention includes a tank body 1 and two beam-type frames 2 symmetrically connected at both ends of the tank body 1 .

[0019] The tank body 1 is a common container tank structure, and the end of the tank body 1 is provided with a head 11 .

[0020] The two-beam frame 2 is symmetrically connected to both ends of the tank body 1. The beam frame 2 includes an end outer frame 21, an upper support member 22 and a lower support member 23, and may also include at least one upper backing plate member 24. At least one pressing structural member 25, at least one lower backing plate member 26 and at least one reinforcing box 27.

[0021] The end outer frame 21 is vertically arranged, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com