Multi-carrier cyclic loading and unloading device

A carrier and cycle conveying technology, which is applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of inapplicability to precision industrial production, low work efficiency, and difficulty in distinguishing, so as to reduce manpower input and operation Convenience and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

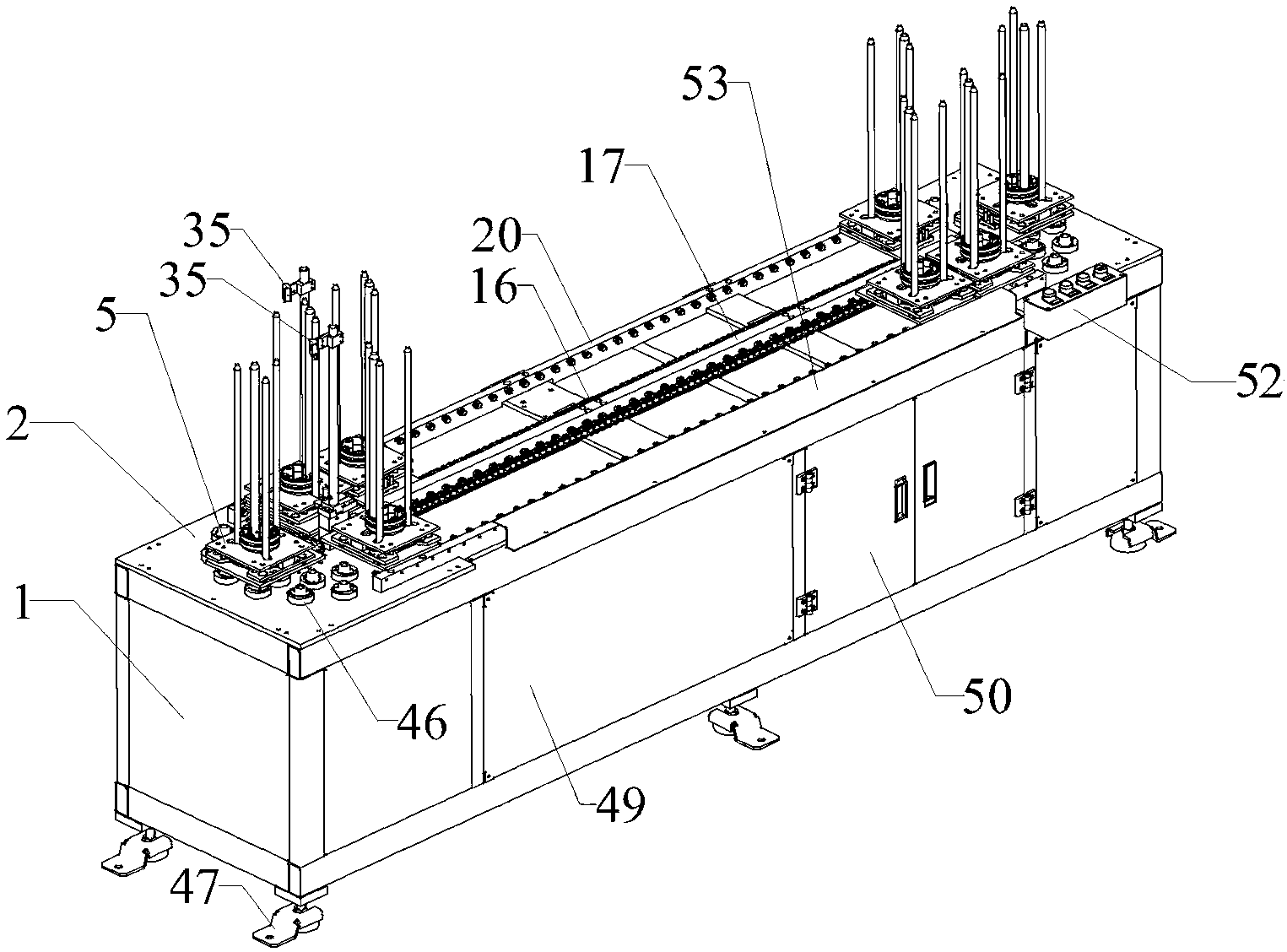

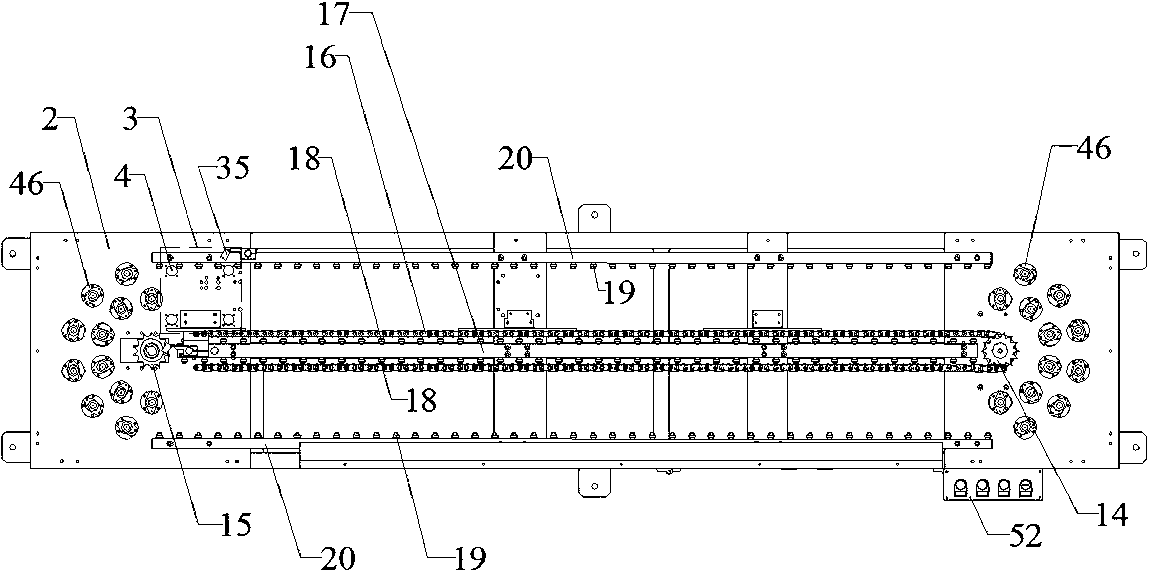

[0040] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

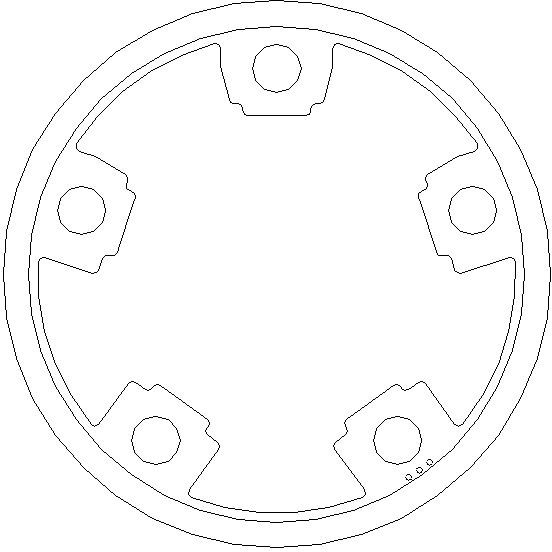

[0041] refer to Figure 2 to Figure 14 As shown, the multi-vehicle circulation loading and unloading device of the present invention mainly includes the following parts:

[0042] a machine 1 with a carrying table 2,

[0043] A plurality of loading units 5 for reciprocating motion on the loading platform 2 of the machine 1,

[0044] A circular conveying system for realizing the reciprocating motion of the loading unit 5,

[0045] A lifting transmission system for lifting and transporting the workpiece 0 on the loading unit 5 in the vertical direction,

[0046] The control system used to control the circular conveying system and the lifting conveying system.

[0047] The machine platform 1 is mainly used to construct a carrying platform 2 and a frame structure for fixing various system components, so that each part can constitute a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com