Automatic dry-type centrifugal roller torque force clutch

An automatic clutch and roller technology, applied in the direction of clutches, mechanical equipment, etc., can solve the problems of reduced clutch service life, low service life, high cost, etc., and achieve the effect of improving work efficiency, increasing service life, and large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

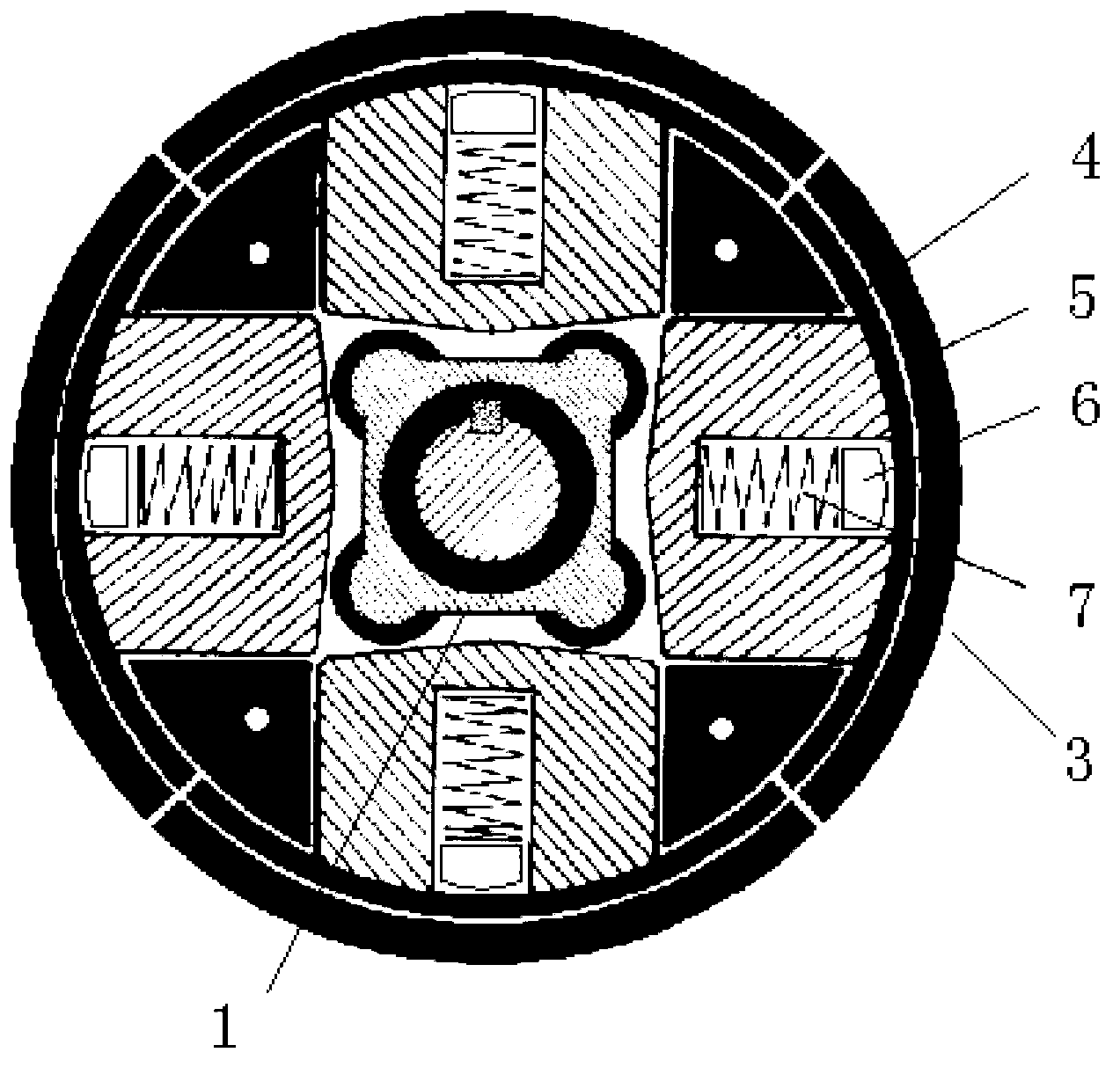

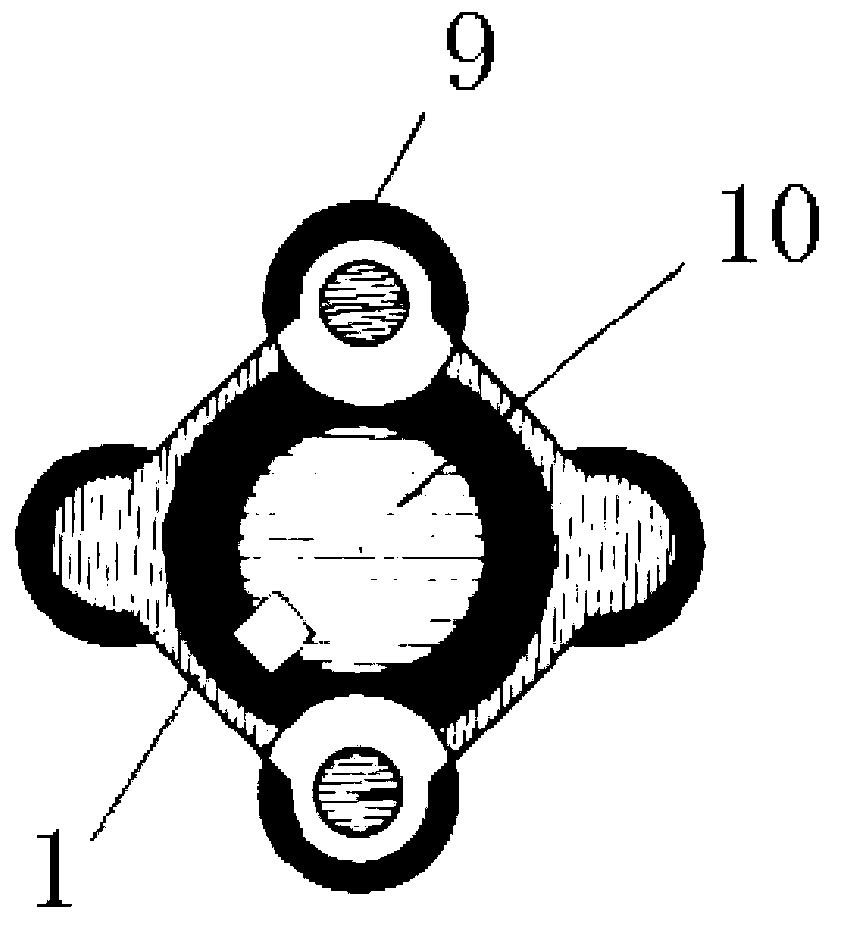

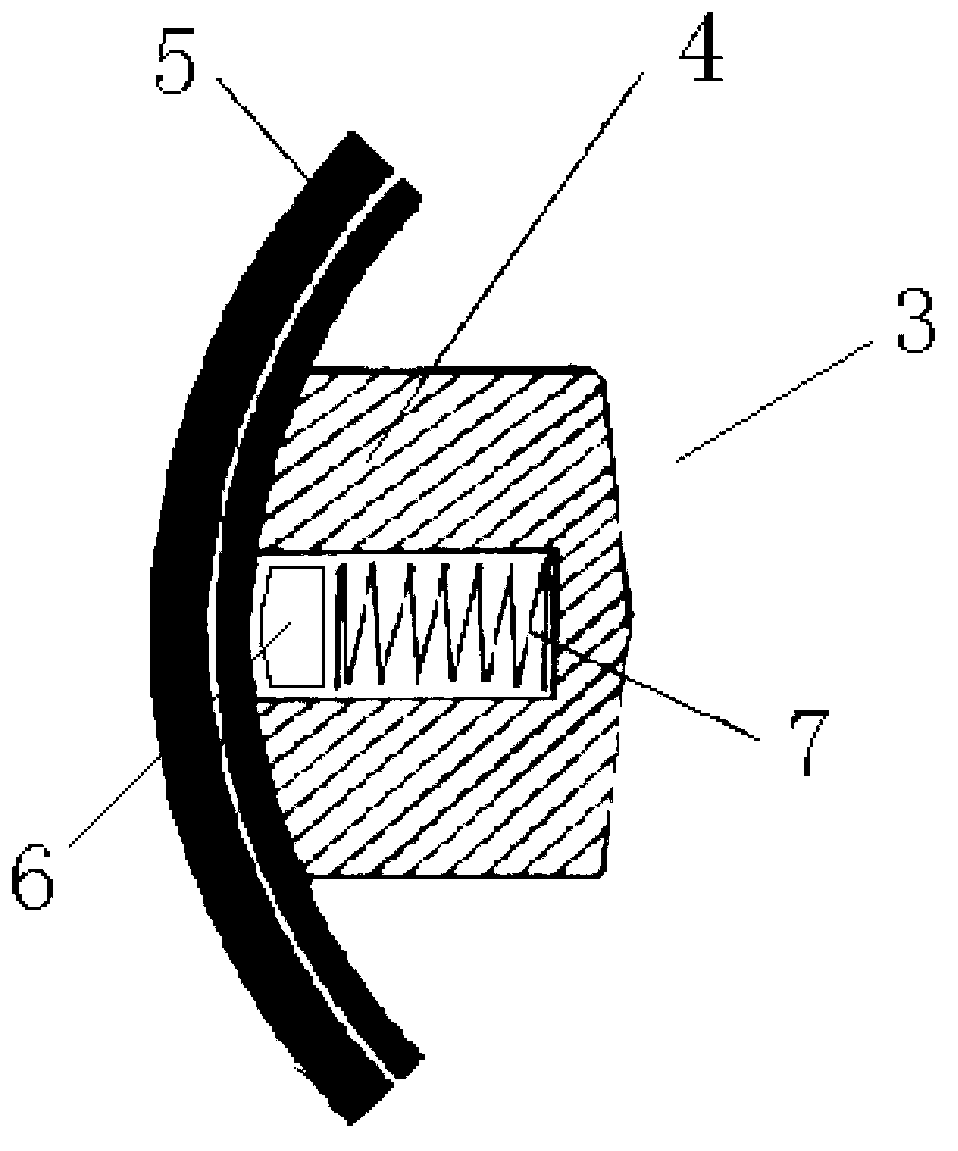

[0019] attached Figure 1-3 It is a dry centrifugal roller torsion automatic clutch according to the present invention, which includes a cam 1, a fixed seat 2, and a slider assembly 3; connection; there are four slider assemblies 3, and the four slider assemblies 3 are respectively arranged around the cam 1; each slider assembly 3 includes a slider 4, a friction plate 5, a fixed arm 6 and a return Spring 7; the slide block 4 is slidably arranged on the fixed seat 2; the friction plate 5 is arranged on the end of the slide block 4 away from the cam 1, and each friction plate 5 extends circumferentially, so that all the friction plates 4 are approximately combined to form a complete circle; the fixed arm 6 is arranged on the fixed seat 2; the return spring 7 is arranged between the slider 4 and the fixed arm 6; the cam 1 is provided with four protrusions Each raised portion 8 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com