Soybean milk steaming device

A soy milk and steam pipe technology, applied in the field of kitchen utensils, can solve the problems of hindering liquid surface contact, hindering the uniform transfer of heat, and sticking the bottom of the pot, so as to achieve the effect of promoting uniform heating, avoiding overflow, and promoting distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

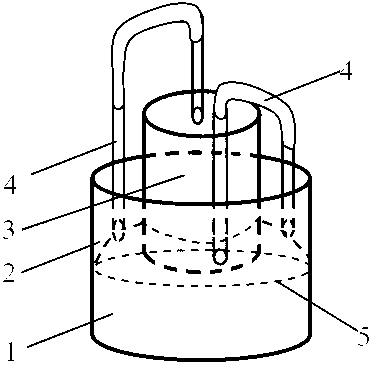

[0010] A device for steaming soybean milk, which is composed of a water container 1, a cover plate 2, a soybean milk container 3 and a steam pipe 4. There is a ring-shaped protruding edge near the middle position of the inner wall of the water container 1 (referred to as the convex edge 5). The outer wall of the soya-bean milk container 3 is connected with an annular trumpet-shaped cover plate 2, and the cover plate 2 rests on the annular rib of the water container 1. Since the soy milk container 3 is located above the water container 1, the bottom area of the soy milk container 3 is smaller than that of the water container. Because of the cross-sectional area of the container 1, there is a larger gap between the water container 1 and the soybean milk container 3, and this gap is sealed by the cover plate 2. There are 2-8 steam pipes 4 on the cover plate 2. The steam pipes 4 guide the steam generated by the water container 1 into the soybean milk container. A part of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com