Double-point compressing device

A technology of a pressing device and a power device, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of large static friction, inconsistent downward pressure on the workpiece, and inability to perform relative motion, and achieves the effect of improving operation speed and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

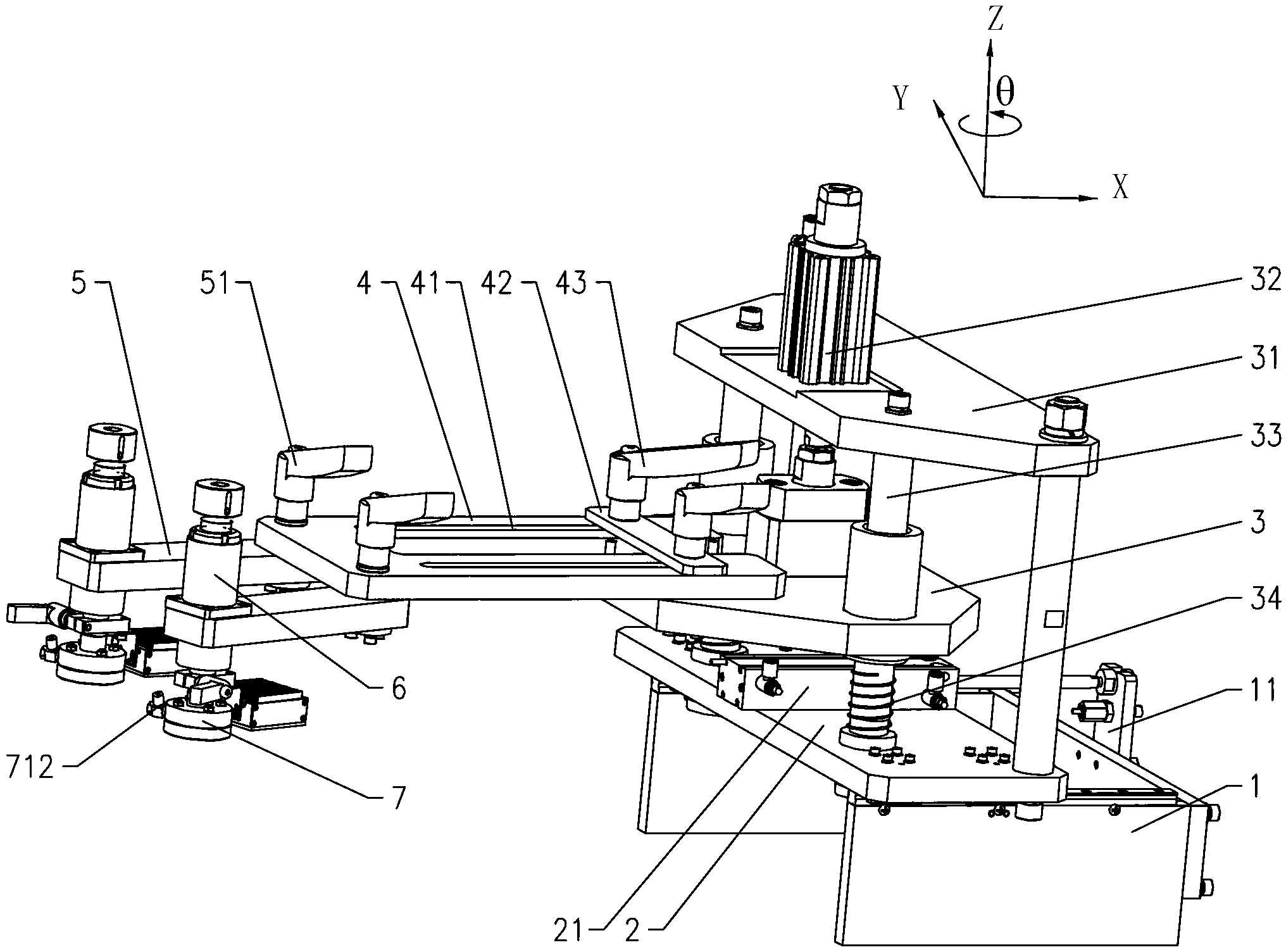

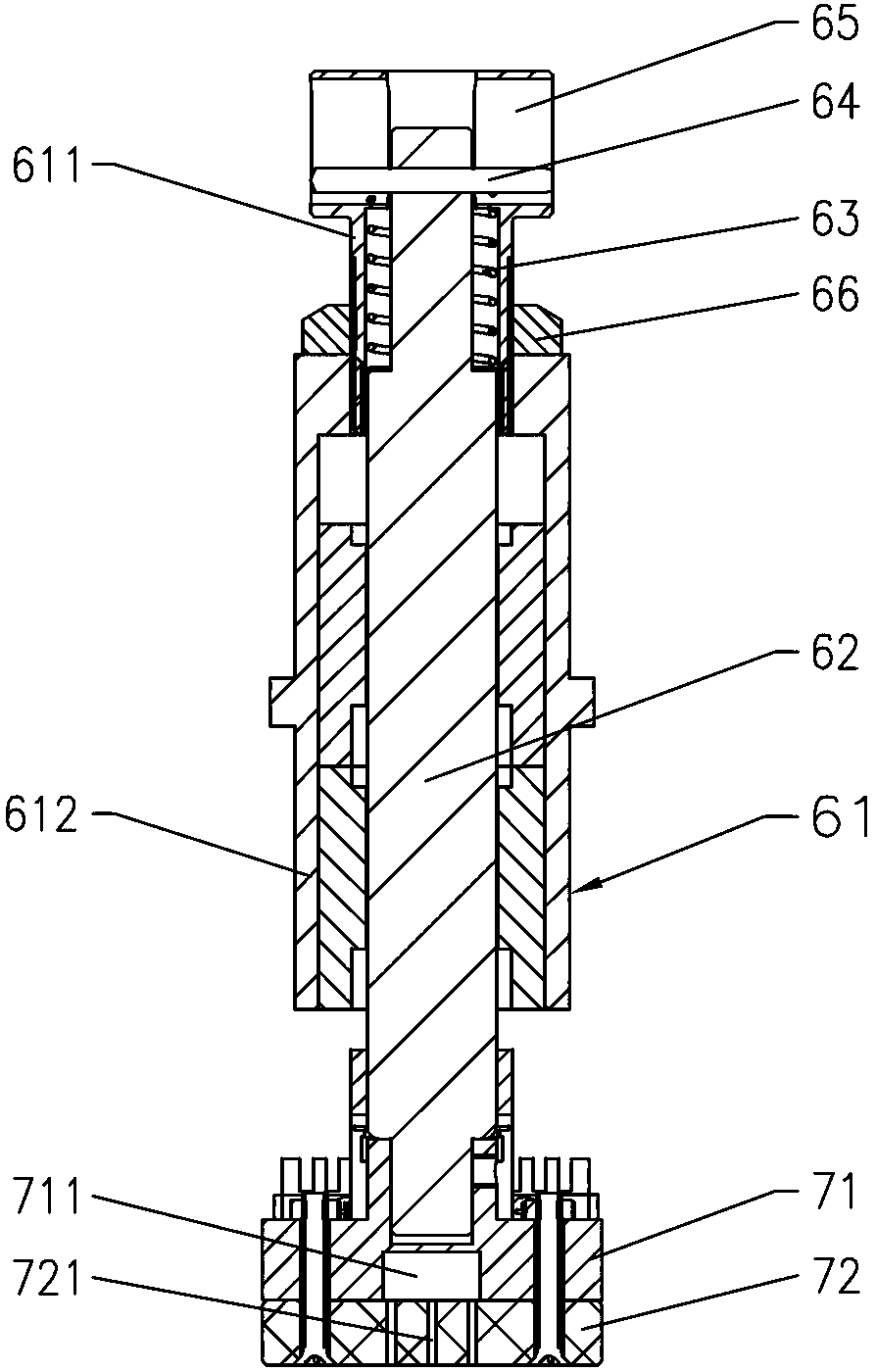

[0026] Such as figure 1 with figure 2 Shown, a two-point pressing device. See X, Y, Z directions in the three-dimensional coordinate system figure 1 , where the X direction and the Y direction are two directions perpendicular to each other in the horizontal plane, and the Z direction is the direction perpendicular to the horizontal plane. The specific structure includes the following parts.

[0027] First include base 1. The X-direction mobile platform 2 driven by the first power device 21 is installed on the base 1. In this implementation process, the first power device 21 adopts a cylinder, and a linear guide rail is installed between the X-direction mobile platform 2 and the base 1. The first power The device 21 is fixed on the X-direction moving platform 2 , and the end of the push rod of the first power device 21 is fixed on the protruding retaining wall 11 of the base 1 .

[0028] The Z-direction mobile platform 3 driven by the second power unit 32 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com