Air-cooled plasma protecting gas hood nozzle

A plasma and protective gas hood technology, applied in the field of plasma processing equipment, can solve the problems of workpiece thermal stress, influence, insufficient reaction, etc., and achieve the effects of reducing thermal influence, reducing cost, and ensuring active atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

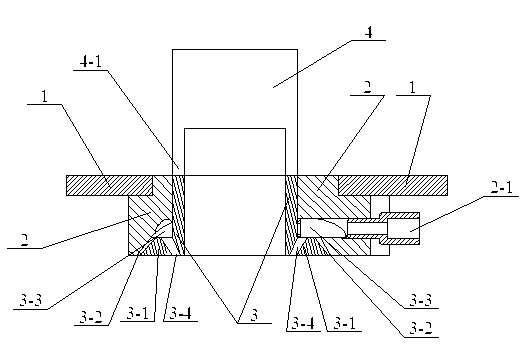

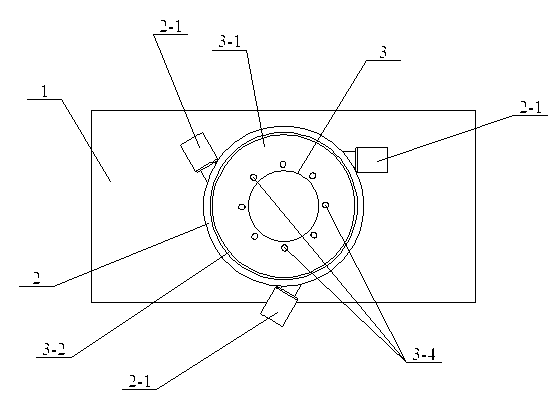

[0018] Specific implementation mode one: combine figure 1 , figure 2 As shown, it consists of a fixed plate 1, a circular tube-shaped protective cover 2, and a circular tube-shaped torch tube extension 3:

[0019] The inner hole of the tubular protective cover 2 is conical, and there are three ventilation holes 2-1 distributed at intervals of 120 degrees on the inner wall to ensure the uniformity of the air flow; the three ventilation holes 2-1 are all connected with the circular tubular protective cover. 2. The circular surface of the inner tapered hole is tangent, so that the gas enters along the tangential direction; a disc 3-1 is arranged on the outer circumference of the lower end of the circular tube-shaped torch tube extension 3, and the outer circular surface of the disc 3-1 is conical , the middle part of the fixed plate 1 is provided with a through hole 1-1, the outer circular surface of the upper end of the circular tube-shaped protective cover 2 is embedded in th...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 , figure 2 As shown, the difference between this specific embodiment and specific embodiment one is that the outer conical surface of the lower end disk 3-1 of the circular tube-shaped torch tube extension 3 is sealed with the lower end inner circular surface of the circular tube-shaped protective cover 2 When connecting, a plurality of air outlet holes 3-4 are uniformly arranged on the circumference of the disc 3-1 at the lower end of the circular tube-shaped torch tube extension 3, and the plurality of air outlet holes 3-4 and the annular air chamber 3-3 conduct gas connected. Other compositions and connections are the same as in the first embodiment.

[0022] Specific implementation mode two: combination figure 1 , figure 2 As shown, the difference between this specific embodiment and specific embodiment 1 lies in the difference between the outer conical surface of the lower end disk 3-1 of the circular tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com