Testing device and testing method of anchor-tension type retaining wall model

A model test device and retaining wall technology, which is applied in the fields of railway engineering, geotechnical engineering, and road engineering, can solve problems such as different force characteristics, achieve convenient transportation, easy processing, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

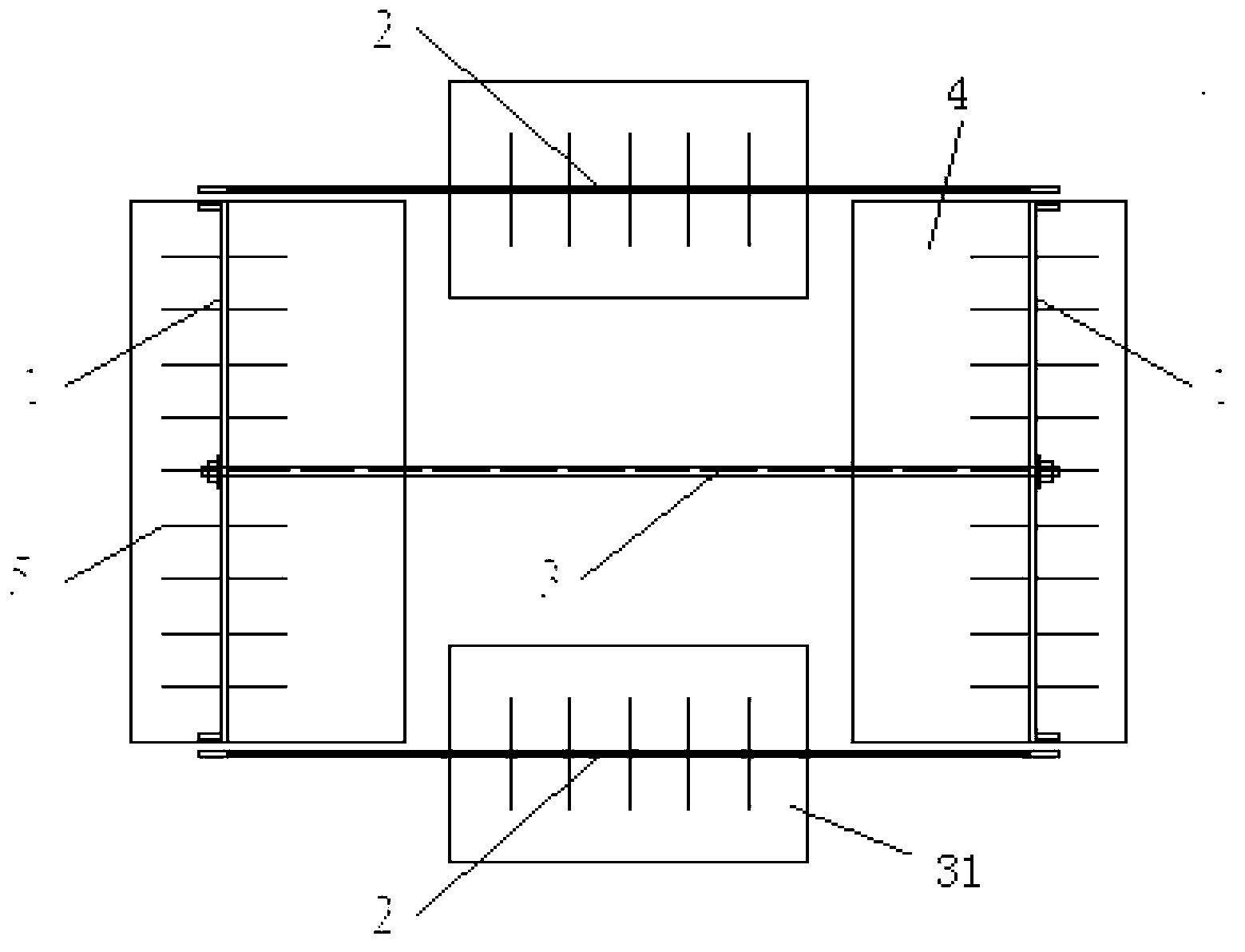

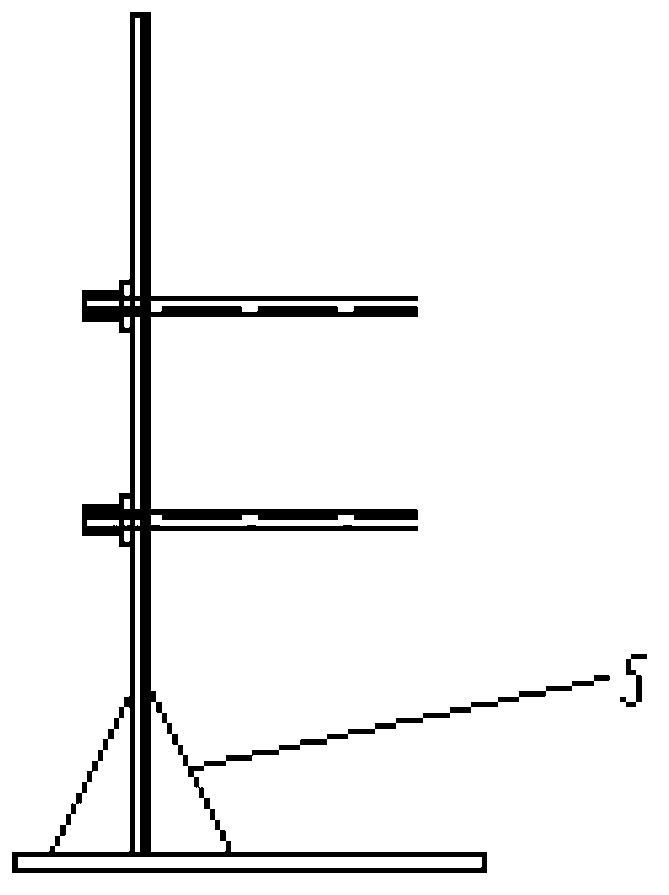

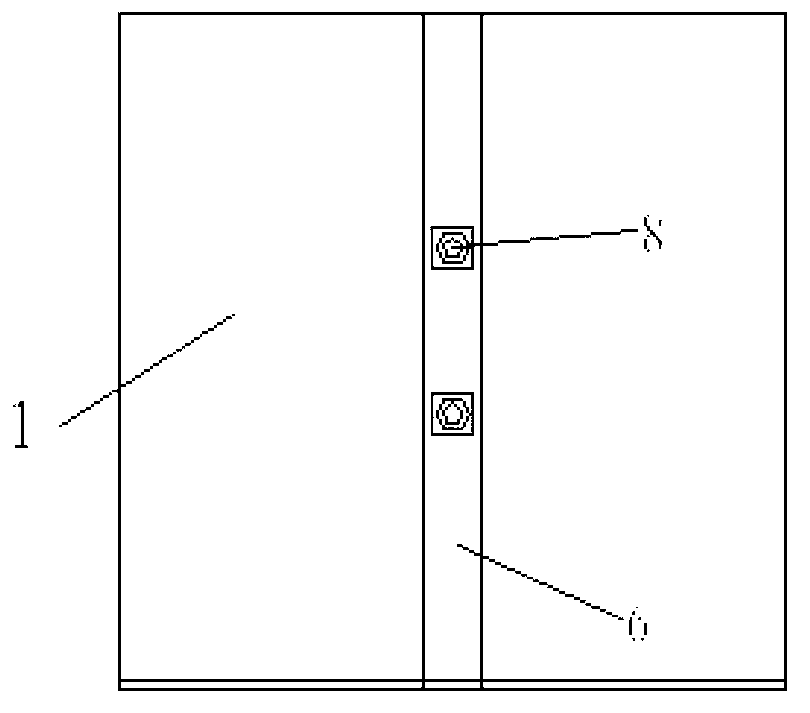

[0049] An anchor pull type retaining wall model test device, combined Figure 1 to Figure 7 , Including the test slot 24, the main bearing surface cantilever retaining wall, the auxiliary bearing surface cantilever retaining wall, the loading system, the test system; the main bearing surface cantilever retaining wall, the auxiliary bearing surface cantilever retaining wall are set in the test slot 24 Inside, the main bearing surface cantilever retaining wall includes a main bearing surface vertical steel plate 1 and a first horizontal steel plate 4 connected, and the main bearing surface vertical steel plate 1 is welded to the first horizontal steel plate 4; The force surface cantilever retaining wall includes the auxiliary force surface vertical steel plate 2 and the second horizontal steel plate 31 connected, the main force surface vertical steel plate 2 and the second horizontal steel plate 31 are welded; the main force surface vertical steel plate 1 The first anchor rod hol...

Embodiment 2

[0079] Among them, the vertical steel plate 1 of the main bearing surface cantilever retaining wall has a thickness of 20mm, a length of 2000mm, and a width of 2000mm. The horizontal steel plate 4 is 30mm thick, 2000mm long and 90mm wide. The height of the auxiliary bearing surface cantilever retaining wall is the same as the main bearing surface cantilever retaining wall. The vertical steel plate 2 of the auxiliary bearing surface cantilever retaining wall is 10mm thick, 2000mm long and 2000mm wide.

[0080] Reinforced ribs 5 are arranged between the vertical steel plates and horizontal steel plates of the main bearing surface cantilever retaining wall and the auxiliary bearing surface retaining wall. The thickness of the reinforced rib 5 is 30mm, the height is 400mm, the bottom length is 200mm, and the uniform spacing is 200mm. The reinforcing rib 5 avoids welding deformation when the vertical steel plate and the horizontal steel plate are welded; the vertical steel plate 1 of ...

Embodiment 3

[0099] The main bearing surface cantilever retaining wall and the auxiliary bearing surface cantilever retaining wall are made of Q235 steel plate, of which the vertical steel plate 1 of the main bearing surface cantilever retaining wall has a thickness of 20mm, a length of 2000mm and a width of 2000mm. The horizontal steel plate 4 is 30mm thick, 2000mm long and 90mm wide. The height of the auxiliary bearing surface cantilever retaining wall is the same as the main bearing surface cantilever retaining wall. The vertical steel plate 2 of the auxiliary bearing surface cantilever retaining wall is 10mm thick, 2000mm long and 2000mm wide.

[0100] Reinforced ribs 5 are arranged between the vertical steel plates and horizontal steel plates of the main bearing surface cantilever retaining wall and the auxiliary bearing surface retaining wall. The thickness of the reinforced rib 5 is 30mm, the height is 400mm, the bottom length is 200mm, and the uniform spacing is 200mm. The reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com