Automatic drill pipe assembly and disassembly mechanism of trenchless horizontal directional drilling machine

A horizontal directional drilling rig, automatic loading and unloading technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of high construction cost, unreliable work, collapse of drilled holes, etc., to achieve fast automatic loading and unloading, stable operation Reliable and labor cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

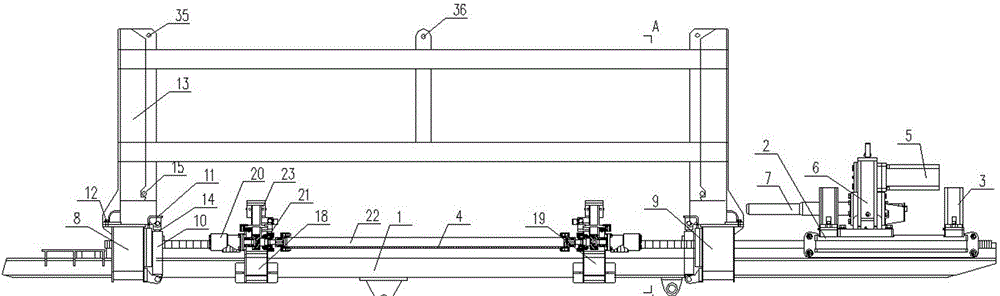

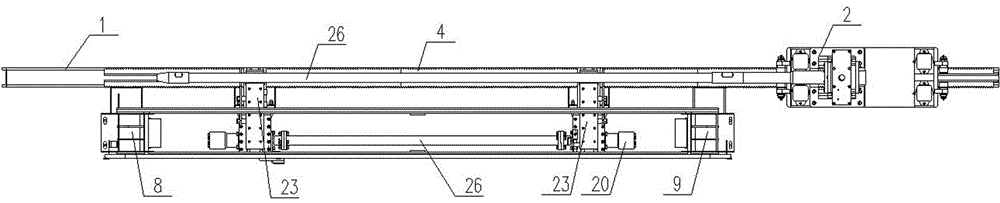

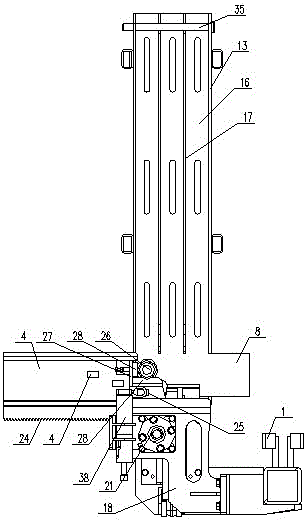

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the non-excavation horizontal directional drilling machine automatically loads and unloads the drilling rod mechanism, including: a beam 1 and a power head device 2 slidingly arranged on the beam 1, and the lower end of the power head device 2 is provided with a power head push-pull motor 3 and a push-pull gear. The push-pull rack 4 cooperating with the push-pull gear is arranged on the beam 1, the upper end of the power head device 2 is provided with a power head rotation motor 5 and a power head rotation gearbox 6, and the power head rotation motor 5 The rotary gear box 6 of the power head is connected with the variable diameter 7, and the left drill box fixing seat 8 and the right drilling box fixing seat 9 are fixedly arranged on the said beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com