Two-prop shielding type electro-hydraulic-control top-coal caving hydraulic support

A hydraulic support and electro-hydraulic control technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of easy damage to the support, moving speed, unbalanced force of the four-column hydraulic support, etc., to improve the overall reliability , Improve structural strength and reliability, and increase the effect of lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

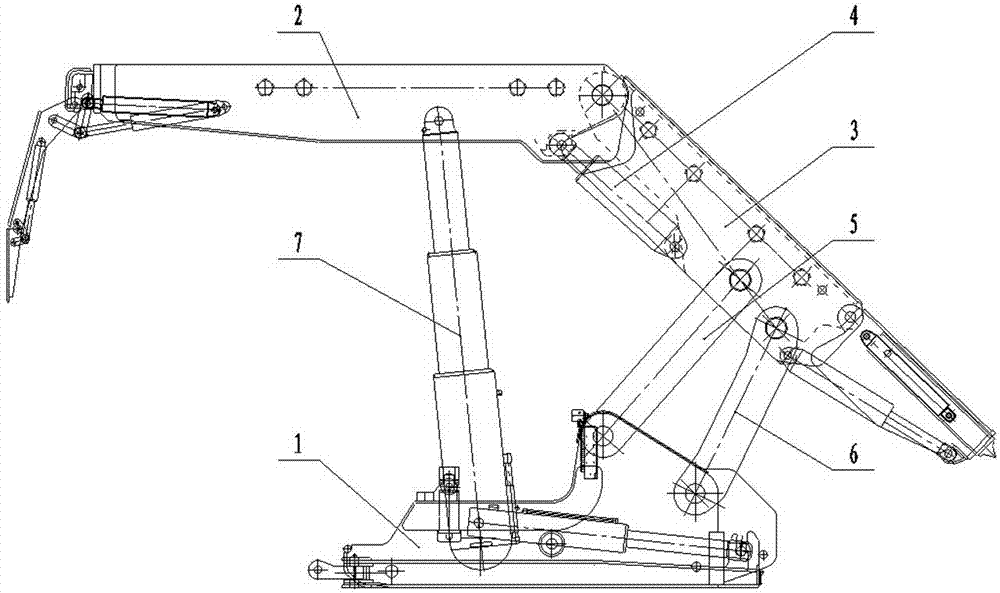

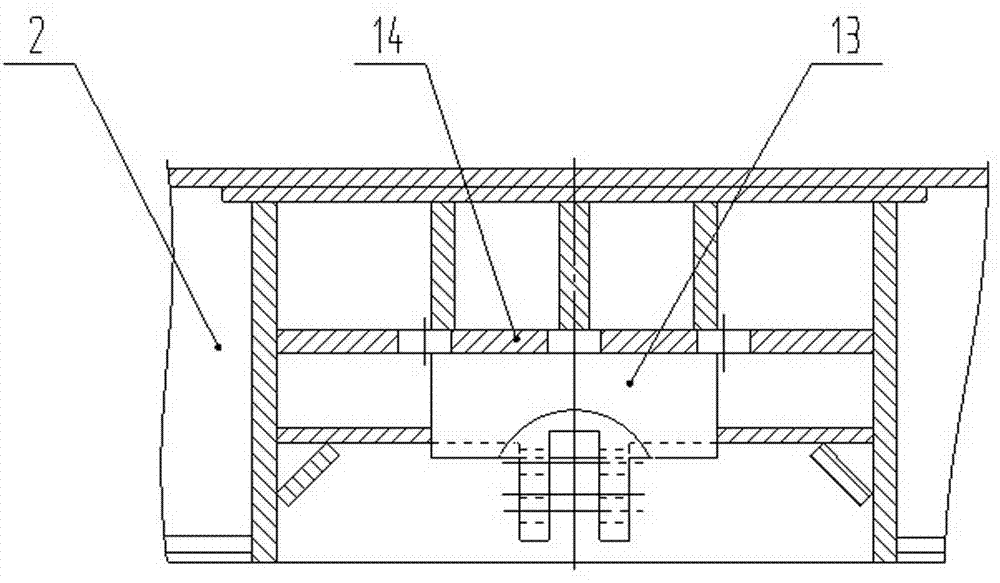

[0022] The two-column shield type electro-hydraulic control top coal caving hydraulic support includes a base 1, a roof beam 2 and a shield beam 3 hinged to the roof beam 2, a balance jack 4 is arranged between the shield beam 3 and the roof beam 2, and the shield beam 3 is connected to the roof beam 2. Between the base 1 there is a front link 5 and a rear link 6 which are hinged to both, the top beam 2 is an integral structure, and between the top beam 2 and the base 1 there are two uprights which are distributed left and right and the top is inclined forward 7. An electro-hydraulic control system communicating with each column 7 is installed in the cavity;

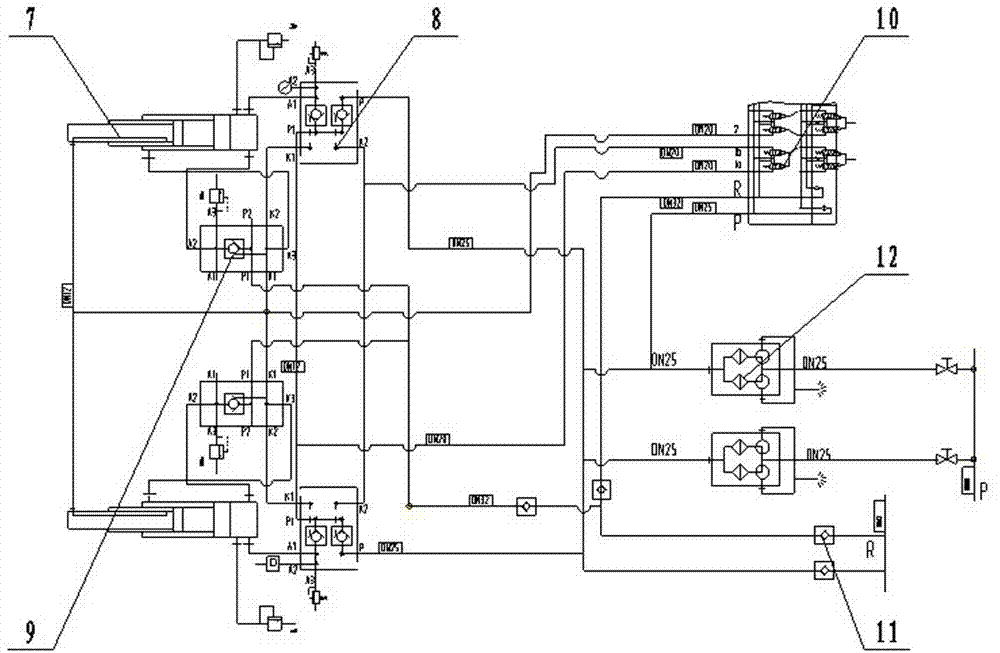

[0023] The electro-hydraulic control system includes a double-inlet and double-return quick-inlet and return system, and the double-inlet and double-circuit quick-inlet and return system includes a rapid liquid supply hydraulic control check valve 8, a hydraulic control check valve 9, an electro-hydraulic control reversin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com