Anti-explosion lamp

A technology of explosion-proof lamps and explosion-proof structures, which is applied in lighting applications, lighting and heating equipment, office buildings, etc., and can solve problems such as not soft, single light distribution of lamps, and heavy lamps with flameproof shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

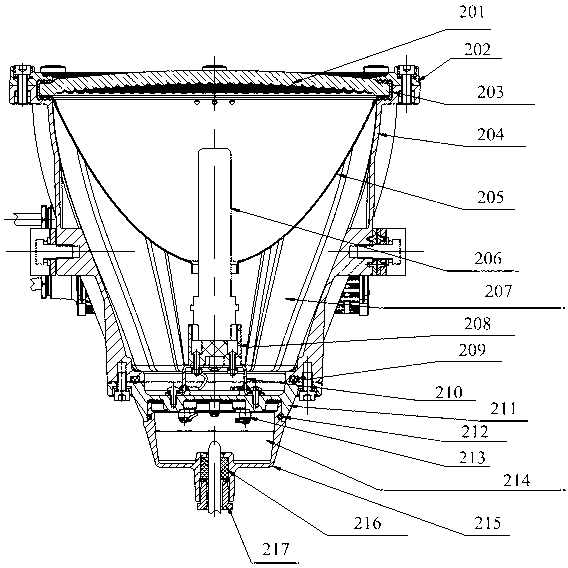

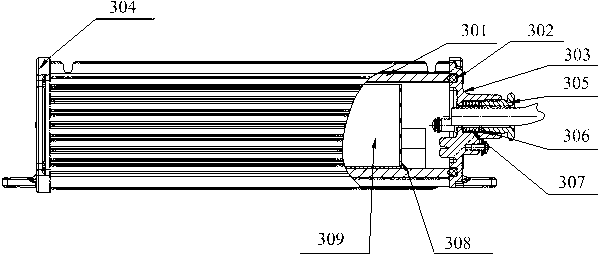

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

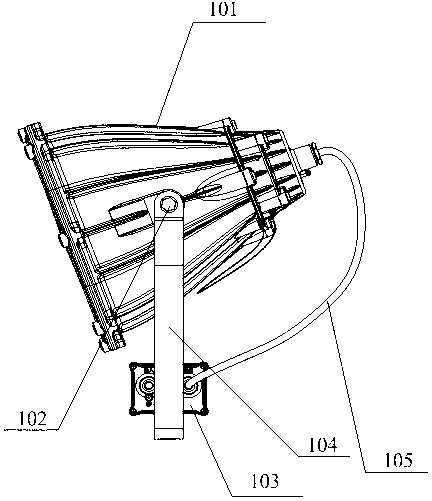

[0020] This embodiment provides an explosion-proof lamp. The explosion-proof lamp is suitable for high-power projection lighting in Zone 2 of potentially explosive hazardous gas environment, such as high-pole lighting in oilfield gathering and transportation stations, projection lighting in oil irrigation areas, factory areas, etc. It can effectively reduce the surface working temperature, facilitate installation, and has good explosion-proof effect.

[0021] like figure 1 As shown, the explosion-proof lamp includes a lamp body 101, an electrical box 103 and a mounting bracket 104, the lamp body 101 is fixed on the upper part of the mounting bracket 104, and the electrical box 103 is fixed on the lower part of the mounting bracket 104; and, the lamp body 101 and the electrical box 103 are respectively The fastener 102 is integrally assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com