A catenary wire wear detection device

A detection device and catenary technology, applied in the detection field, can solve the problems of measurement accuracy limitation and high detection cost, and achieve the effects of convenient operation, reliable work, high detection efficiency and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

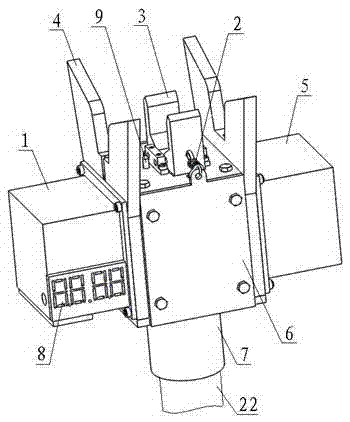

[0028] like figure 1 As shown, the cross-section of the catenary conductor to be detected is an irregular circle, and the notches on both sides of the upper part are used for sling clamping. The worn part is the lower part of the conductor, when the catenary conductor is excessively worn (such as figure 2 As shown), the cross-section of the wire is too small will cause the current density to flow too high, which will cause an accident.

[0029] see Figure 3 ~ Figure 11 , the device includes a measurement control system, a clamping clamp return spring 2, a clamping clamp 3, a guide plate 4, a housing 6, an insulating rod joint 7, a display 8, a guide block 10, a differential transformer return spring 11, a detection cam 12, Lifting cam 13, drive shaft 14, lifting block 15, differential transformer 16, guide column 17, sleeve 19, bearing 20, stepper motor 21, insulating rod 22.

[0030] The bottom of shell 6 is provided with 4.5 meters long insulating rod 22, to facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com