Loading device used in road seam filling material low-temperature performance test

A technology for loading devices and filling materials, which is applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc. It can solve the problems of slow installation speed of test pieces and affect test accuracy, and shorten the installation time , high test efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

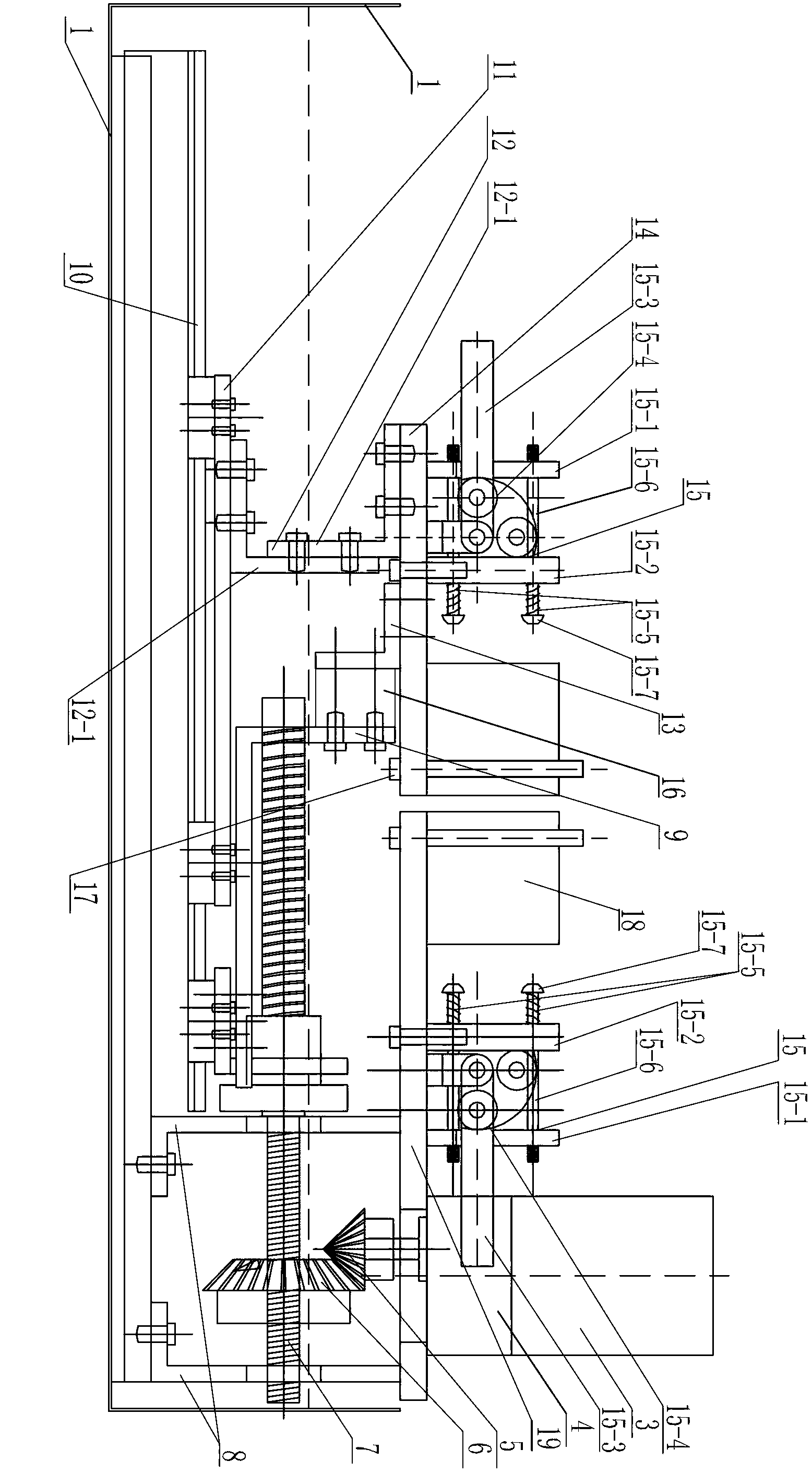

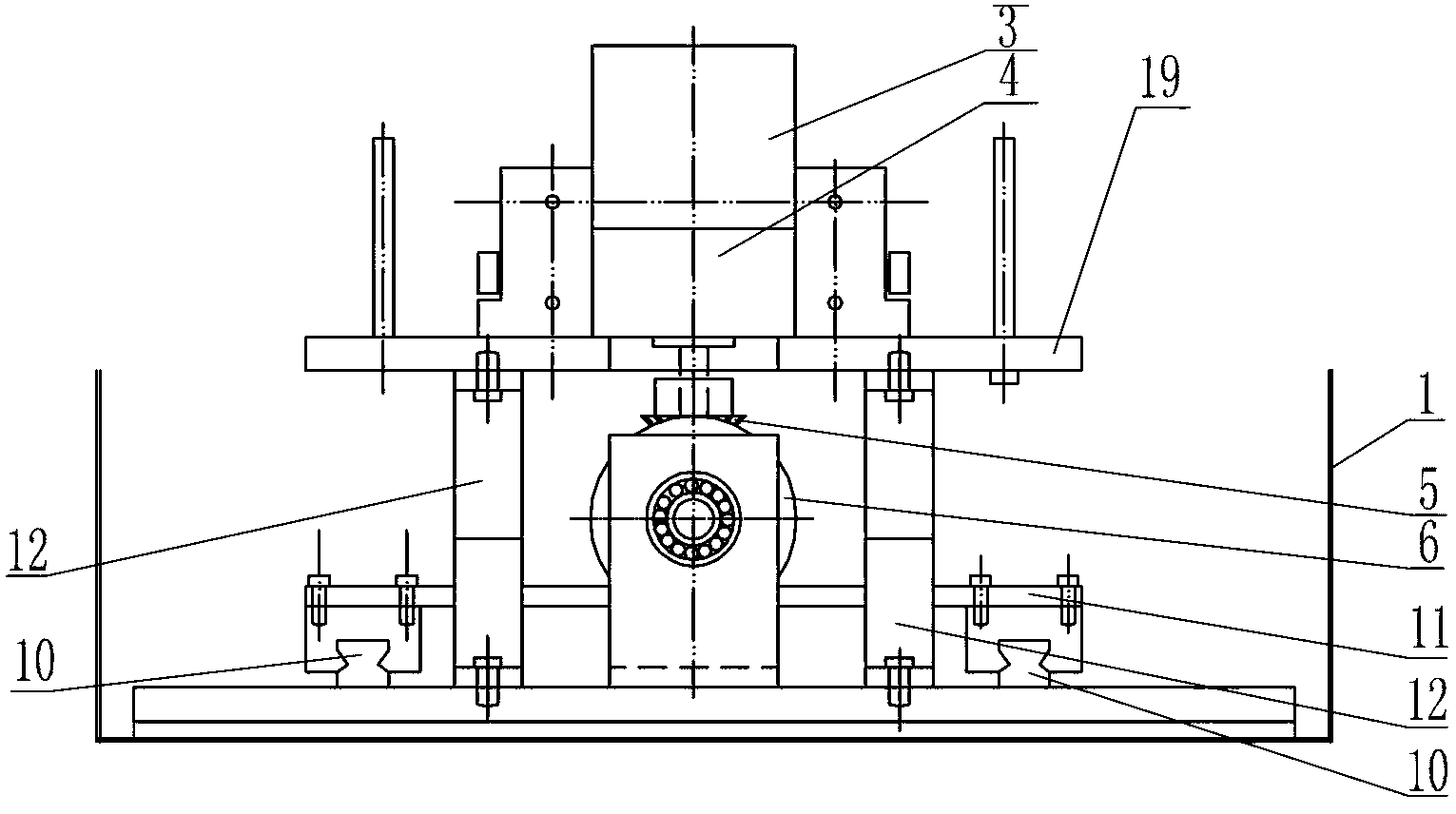

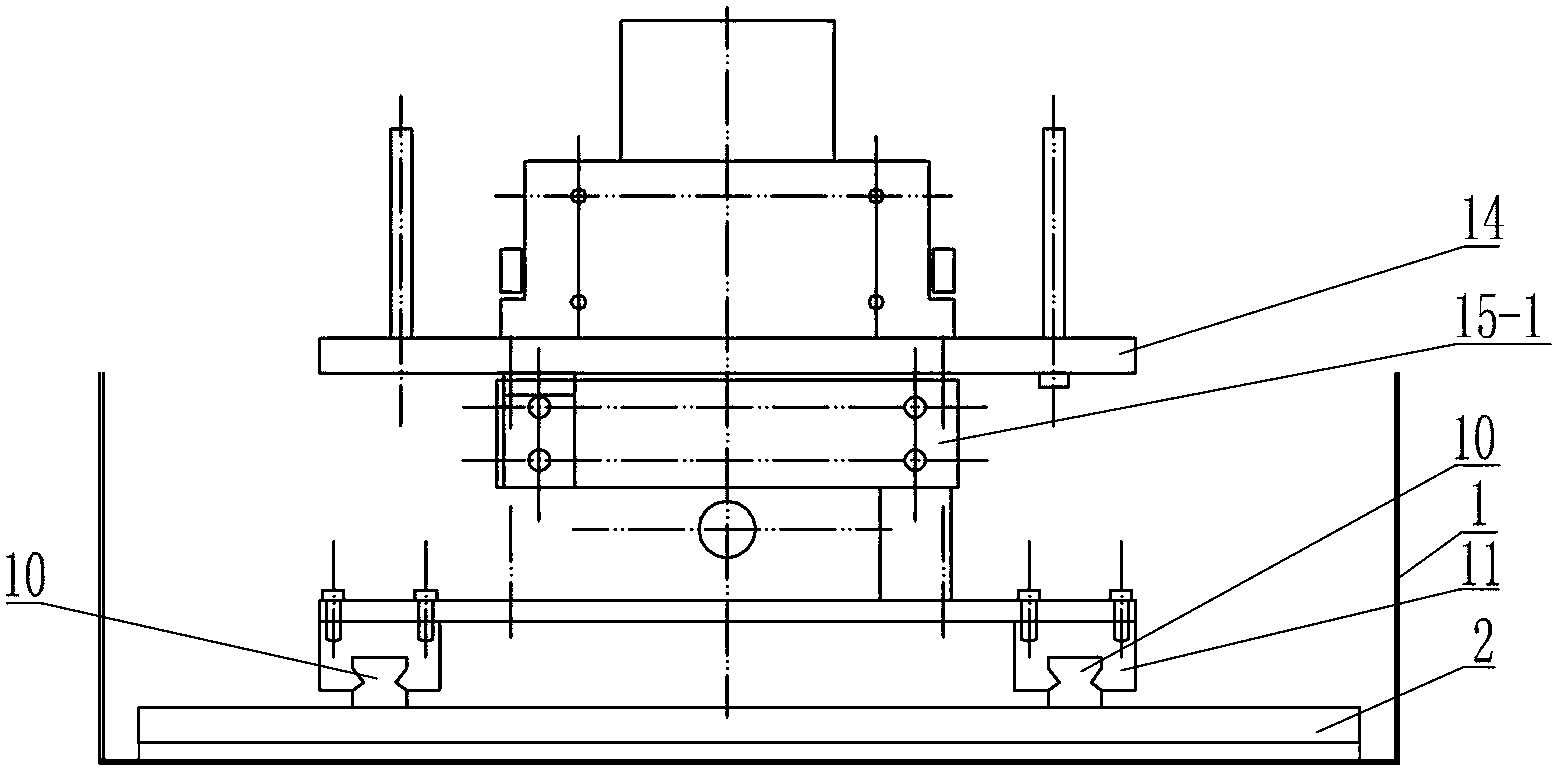

[0013] Specific implementation mode one: combine Figure 1 ~ Figure 4 To illustrate this embodiment, a loading device for testing the low-temperature performance of road joint filling materials in this embodiment includes an oil tank 1, a bearing plate 2, a transmission unit, a support sliding unit, and a loading unit;

[0014] The transmission unit includes a motor 3, a reducer 4, a first bevel gear 5, a second bevel gear 6, a transmission shaft 7, a fixed frame 8 and a transmission member 9;

[0015] The supporting slide unit includes a slide rail 10, a slide plate 11, a connection assembly 12 and a transition plate 13;

[0016] The loading unit includes a pressure sensor 16, a mobile loading platform 14, a fixed loading platform 19 and two sets of fixtures 15;

[0017] Fixture 8 is installed on the bearing plate 2 that is arranged on the bottom end surface of oil tank 1, and slide rail 10 is installed on the bearing plate 2, and slide plate 11 is installed on the slide rai...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the connection assembly 12 in this embodiment includes two connection plates 12-1, both of which are L-shaped, and the horizontal section of one connection plate 12-1 is detachably connected to the slide plate 11 , wherein the vertical section of one connecting plate 12-1 is detachably connected to the vertical section of the other connecting plate 12-1, and the horizontal section of the other connecting plate 12-1 is detachably connected to the corresponding platform 14. With such a setting, the connection and installation are convenient, and the design requirements and actual needs are met. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 Describe this embodiment, the device described in this embodiment also includes a stop post 17, the stop post 17 is vertically arranged, the stop post 17 is installed on the lower end surface of the platform 14 connected with the slide plate 11, and the transmission member 9 is located between the transition plate 13 and the stop. Between columns 17. Such arrangement facilitates the blocking of the transfer member from retreating. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com