Sole frictional wear experiment machine

A friction and wear and experimental machine technology, applied in the direction of testing wear resistance, can solve the problems of increased sole wear, environmental pollution, waste of resources, etc., and achieve the effect of reducing sole wear, reducing pollution, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

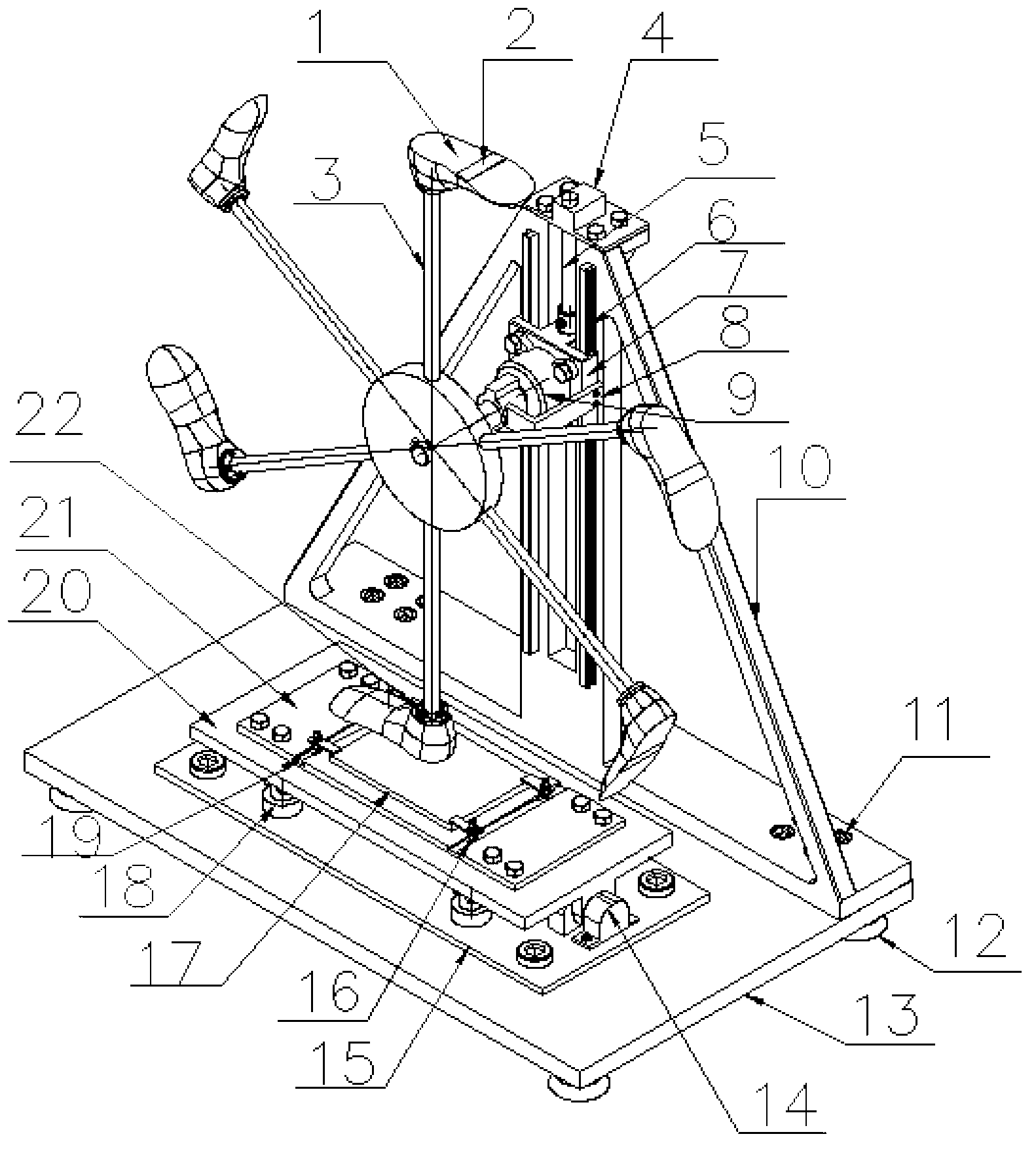

[0014] Such as figure 1 As shown, a shoe sole friction and wear testing machine includes a test bench base 13, a test bench 20, a support 10, a controllable normal pressure cylinder 4, a cylinder connecting rod 5, a slide plate 7, a drive motor 9, a torque sensor 8, a shoe last 1. Elastic material 2, shoe last connecting rod 3 and sample clamping device 16, the bracket 10 is fixed on the base 13 of the test bench by fastening screws 11, and a transition plate 15 is set on the base 13 of the test bench. 20 is installed on the transition plate 15 by four symmetrically distributed controllable angular displacement cylinders 18, the angular displacement sensor 14 for measuring the inclination of the test bench 20 is installed on the transition plate 15, and the sample pad is set on the test bench 20 plate 21, the sample backing plate 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com