Carbon dioxide adsorption isotherm precision testing method

A technology of adsorption isotherm and test method, applied in the direction of analyzing materials, instruments, etc., can solve the problems of low reliability and large result error, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

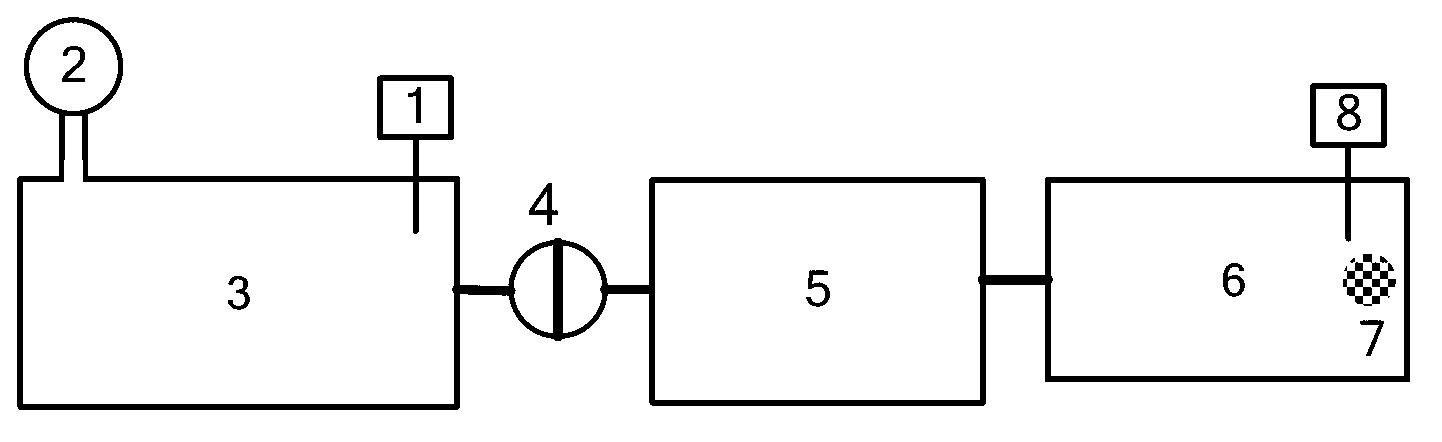

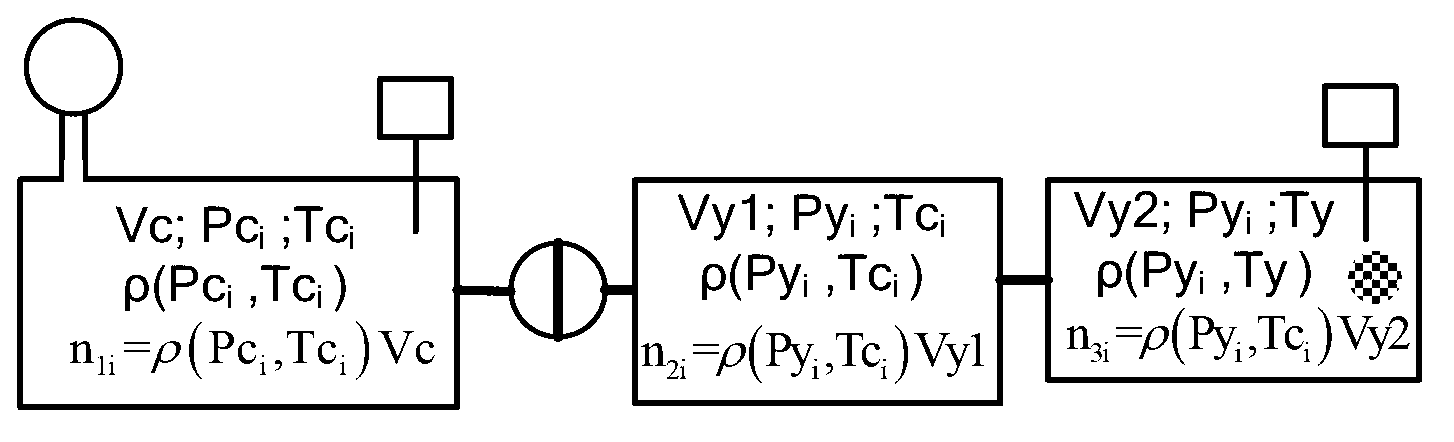

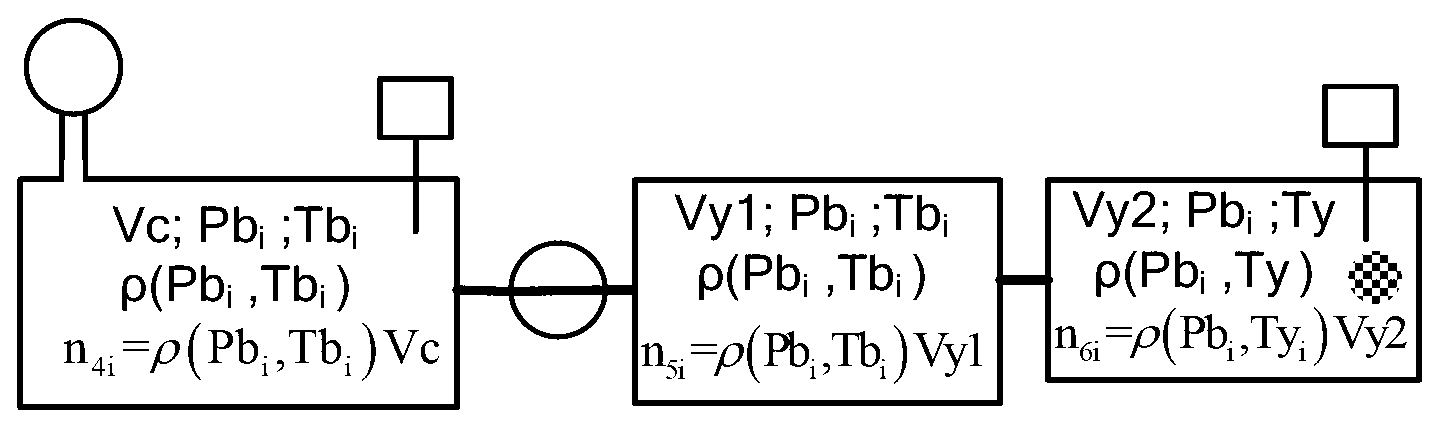

[0029] The method of the present invention uses a device such as figure 1 As shown, the device includes a temperature sensor 1, a pressure sensor 2, a gas storage chamber 3, a valve 4, a connecting pipe 5, a sample chamber 6, CO 2 Adsorption material 7, temperature sensor 8. The gas storage chamber 3 is equipped with a temperature sensor 1 and a pressure sensor 2; the sample chamber 6 is equipped with a temperature sensor 8, which contains CO 2 The adsorption material 7 ; the gas storage chamber 3 and the sample chamber 6 are connected through a connecting pipe 5 , and a valve 4 is arranged on the connecting pipe 5 .

[0030] The invention provides a method for accurately measuring CO2 adsorption isotherms, comprising the following steps:

[0031] 1. Weigh a material with a certain mass m and put it into the sample chamber;

[0032] 2. The temperature sensor 1 measures the temperature of the gas storage chamber and the temperature of the sample chamber, the pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com