Display substrate, display device and manufacturing method of display substrate

A technology for display substrates and manufacturing methods, applied in optics, instruments, electrical components, etc., can solve problems such as product yield decline, picture display quality decline, color film surface unevenness, etc., to eliminate height differences and improve picture display quality , Improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

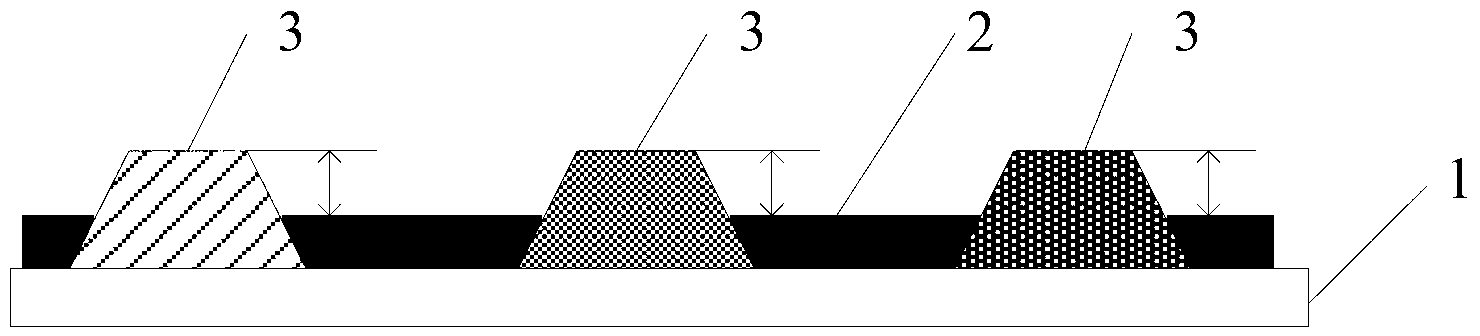

[0023] The display substrate provided by the embodiment of the present invention, such as figure 1 As shown, it includes a substrate substrate 1, a black matrix 2 formed on the substrate substrate 1, and a color filter 3 formed on the substrate substrate 1 with a height difference from the black matrix 2, and also includes: located on the black matrix 2, Or a flat layer located on the black matrix 2 and the color filter 3 , the flat layer is used to flatten the height difference between the black matrix 2 and the color filter 3 .

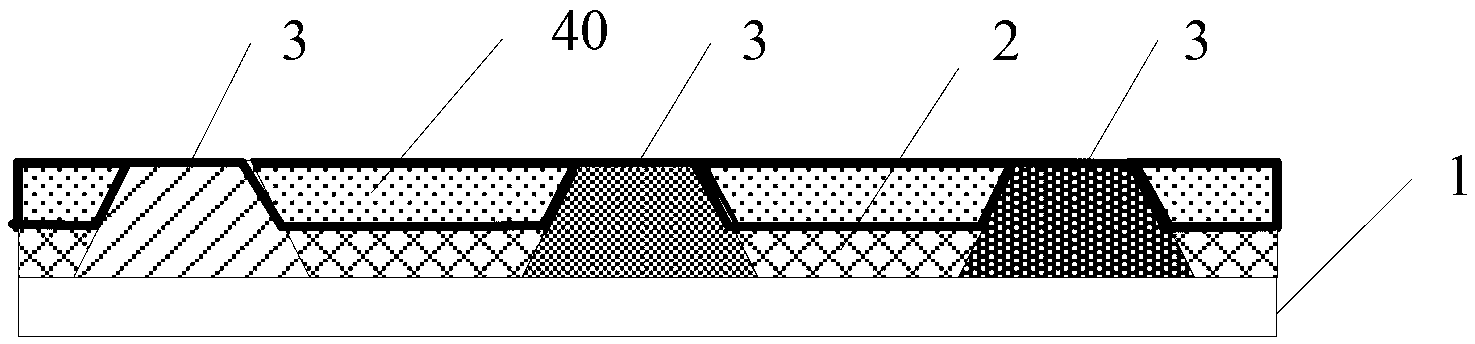

[0024] Further, in the embodiment of the present invention, the planarization layer used to planarize the height difference between the black matrix 2 and the color filter 3 can be preferably photoresist, which can be produced by simple photolithography technology, simplifying the production process.

[0025] When the photoresist is selected as the flat layer in the embodiment of the present invention, the schematic diagram of the substrate structur...

Embodiment 2

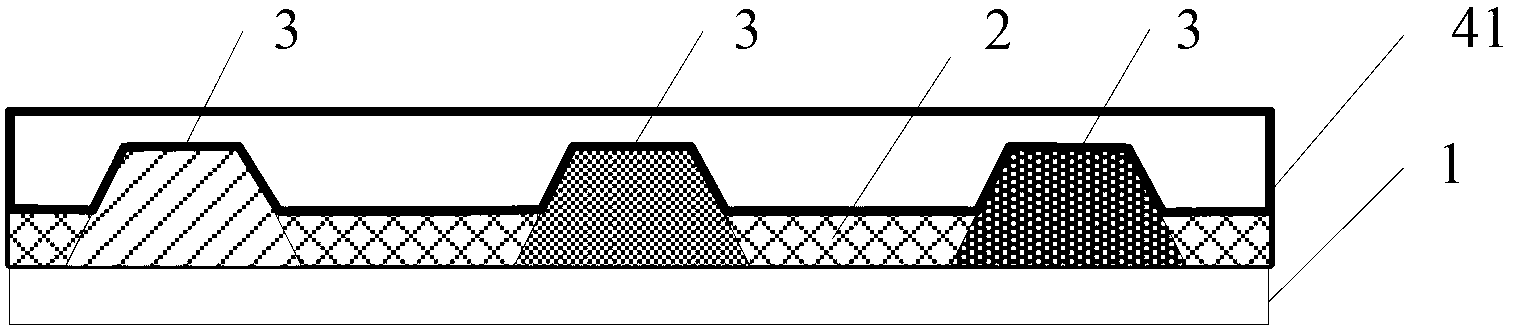

[0029] In the display substrate provided by Embodiment 2 of the present invention, a transparent photoresist is selected as the flat layer, and the transparent photoresist can be placed on the color film, such as image 3 Shown is a schematic diagram of the display substrate structure provided by the embodiment of the present invention, including a substrate substrate 1, a black matrix 2 formed on the substrate substrate 1, and a color filter 3 formed on the substrate substrate 1 with a height difference from the black matrix 2 , also includes: a transparent photoresist 41 located on the black matrix 2 and the color filter 3, wherein the upper surface of the transparent photoresist 41 is a horizontal plane, that is, the transparent photoresist 41 is at the position of the corresponding area of the black matrix 2 Different layer heights than those in the corresponding regions of the color filter 3 eliminate the height difference between the black matrix 2 and the color filter ...

Embodiment 3

[0032] In the display substrate provided in Embodiment 3 of the present invention, the flat layer includes a transparent resin 42 and a photoresist 43, the transparent resin 42 covers the black matrix 2 and the color filter 3, and the photoresist 43 covers the transparent resin corresponding to the area of the black matrix 2, And the upper surface of the photoresist 43 is located on the same horizontal plane as the upper surface of the transparent resin corresponding to the color filter area, such as Figure 4 shown.

[0033] It should be noted that the material of the transparent resin 42 in the embodiment of the present invention may be a transparent organic resin material, a transparent inorganic resin material or other materials that can achieve the purpose of the present invention.

[0034] The embodiment of the present invention provides a flat layer comprising transparent resin and photoresist. Due to the double-layer structure, the height difference between the black...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com