PLC-based (programmable logic controller-based) knife switch control method and system

A control method and control system technology, applied to electrical components, electric switches, circuits, etc., can solve problems such as difficulty in changing locking conditions, non-reusable auxiliary contacts, complicated circuit wiring, etc., to achieve easy changing of locking conditions, electrical operation circuit Reliable and Simplified Circuit Wiring Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

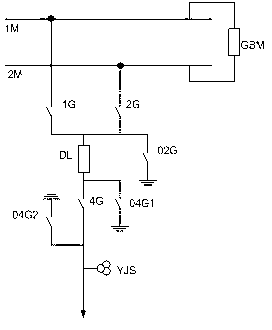

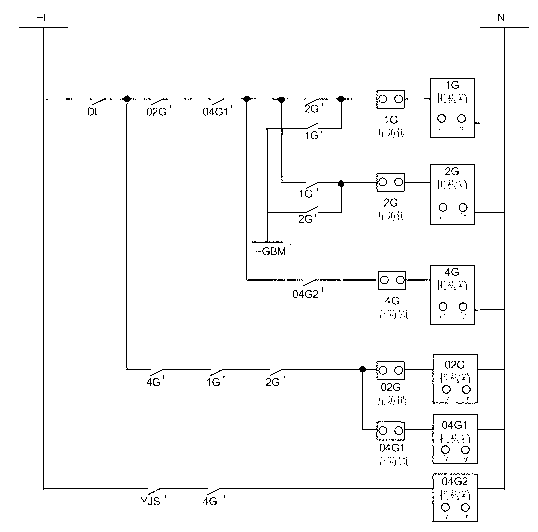

[0036] Attached below figure 1 , 3 A kind of PLC-based knife switch control method and system of the present invention are further described:

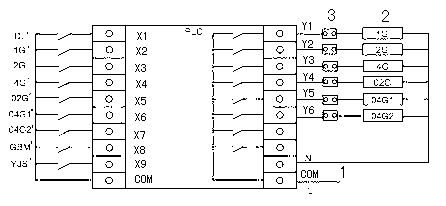

[0037] A PLC-based knife switch control system of the present invention includes a bus tie switch GBM on the bus 1M and 2M, a switch DL in a certain interval, isolating knife switches 1G, 2G, 4G, grounding knife switches 02G, 04G1, 04G2, lines Voltage relay YJS, and PLC, AC power supply 1, mechanism box 2 of each switch and several five-proof locks 3, switch DL, isolation switch 1G, 2G, 4G, grounding switch 02G, 04G1, 04G2, bus coupler One end of the auxiliary contacts DL', 1G', 2G', 4G', 02G', 04G1', 04G2', GBM', YJS' of the switch GBM and the line voltage relay YJS correspond to the X1~X9 input terminals of the PLC one by one Connected, the other end of them is connected in parallel to the COM input terminal of the PLC, and the position information switch value is sent to the PLC, so that the PLC can share information with other pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com