Cutting tool and method for manufacturing cut product using same

A cutting tool and cutting edge technology, applied in tool holders, cutting blades, manufacturing tools, etc., can solve the problems of poor reproducibility of cutting inserts, easy rotation of cutting inserts, and difficulty in fitting tolerances of cutting tools, etc. Achieves the effect of suppressing mounting stability and improving reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

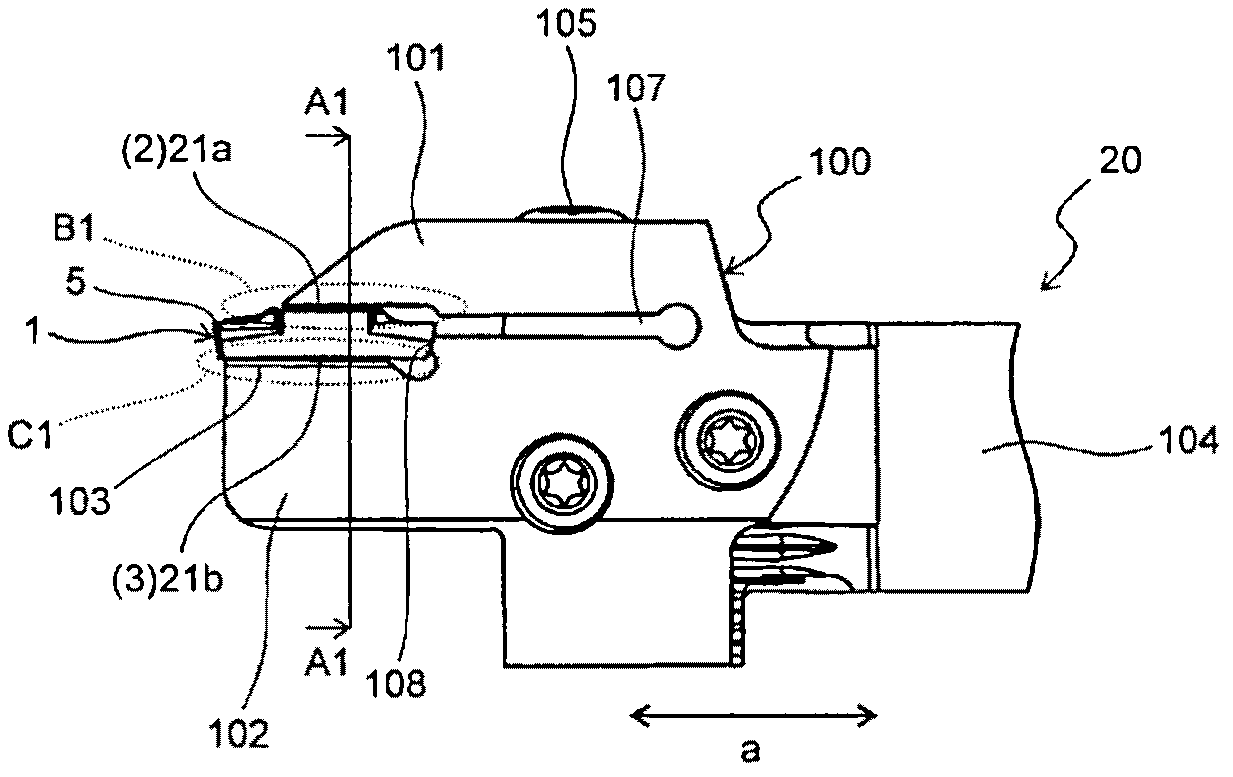

[0024] Below, use Figure 1 to Figure 6 A first embodiment of the cutting tool according to the present invention will be described.

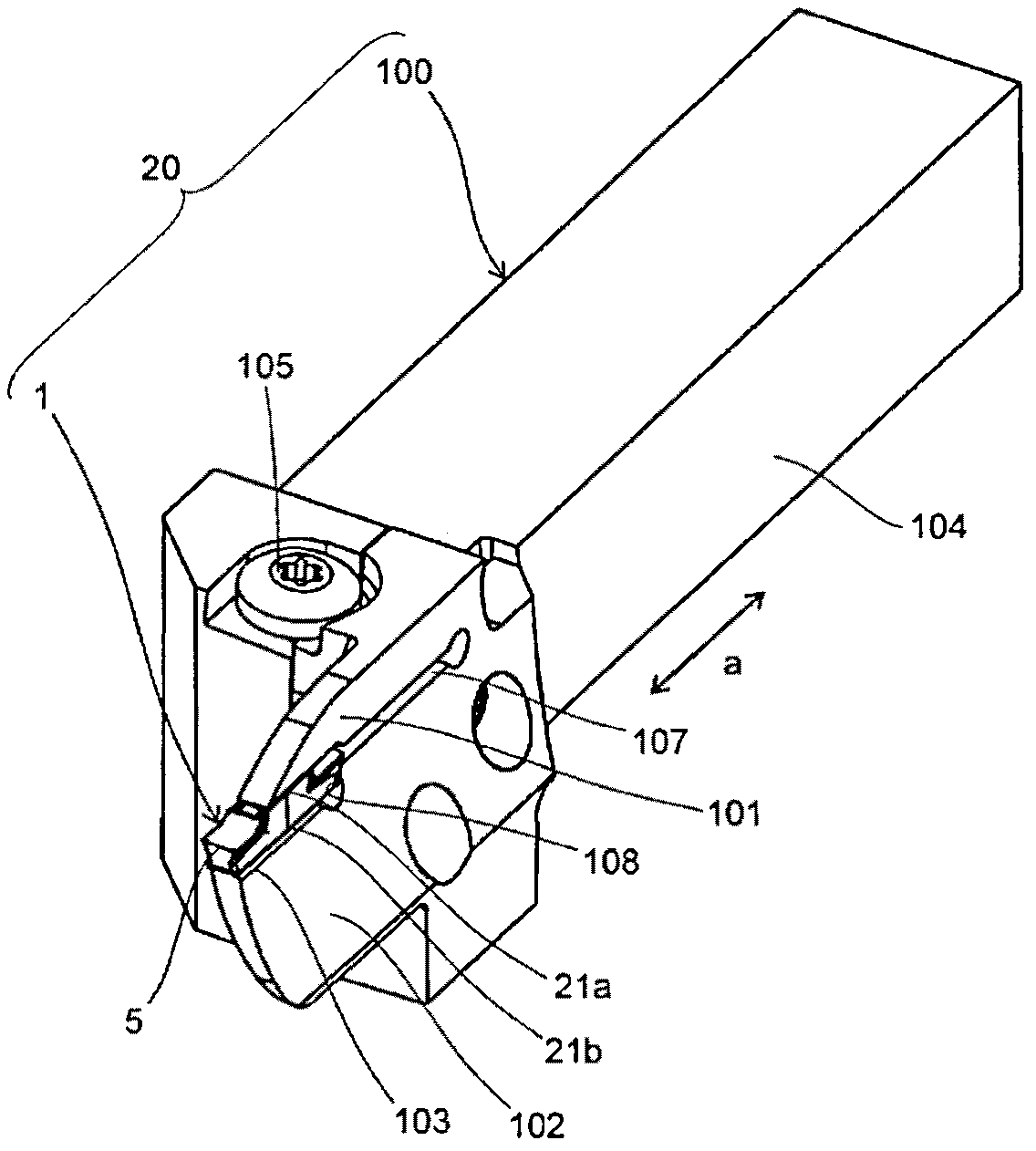

[0025] Such as figure 1 and figure 2 As shown, the cutting tool 20 of the present embodiment has a substantially prismatic shape, and includes a cutting insert (hereinafter, sometimes referred to as an “insert”) 1 and a holder 100 for fixing the insert 1 at the front end.

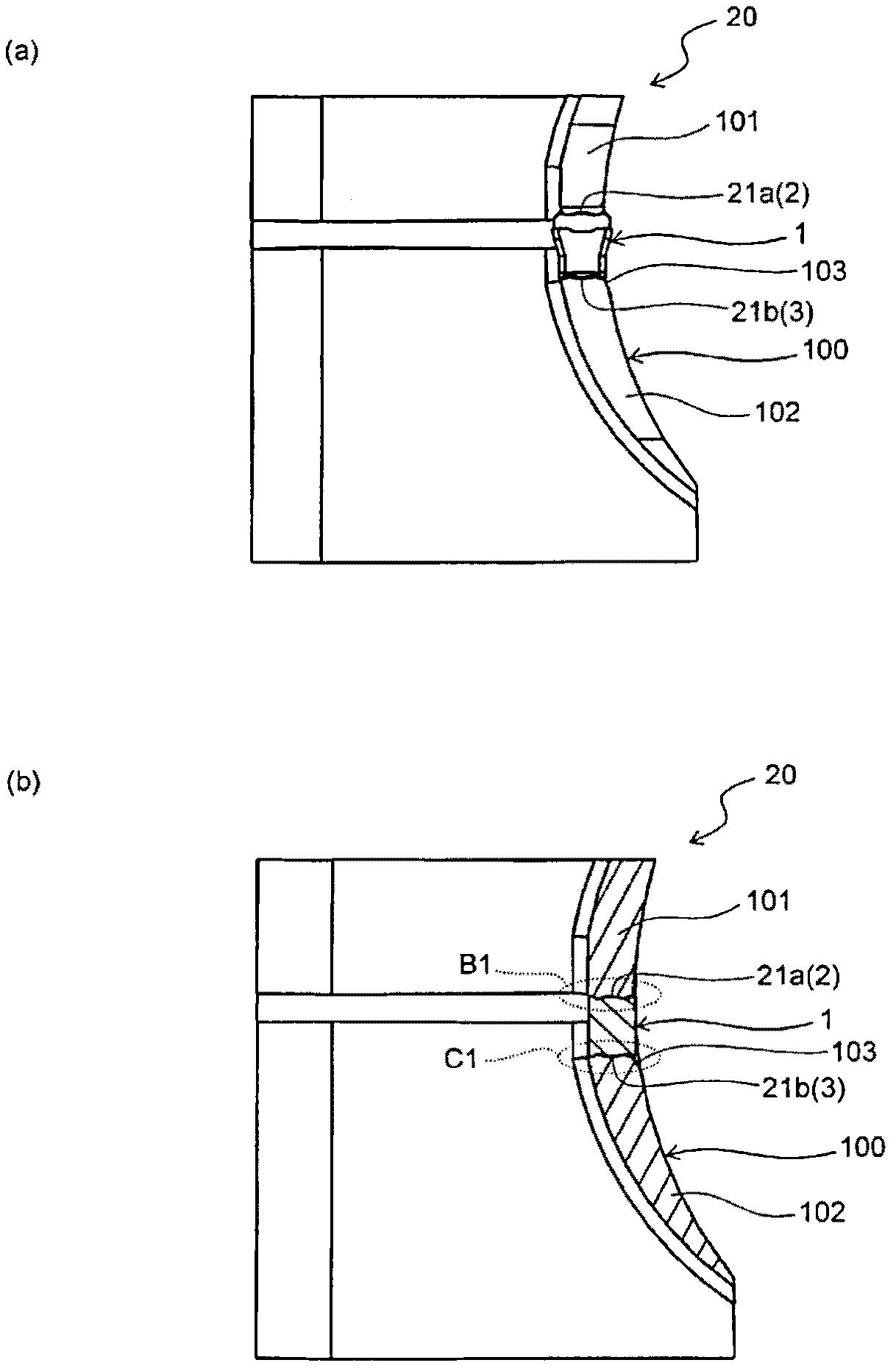

[0026] as described later Figure 6 As shown, the insert 1 has an upper surface 2 , a lower surface 3 and a cutting edge 5 on at least a portion of the upper surface 2 . Additionally, if figure 1 and figure 2 As shown, the holder 100 has an upper flange portion 101 and a lower flange portion 102 for fixing the insert 1 from the upper surface 2 and the lower surface 3 at the front end portion in the longitudinal direction indicated by the arrow a. Furthermore, the insert 1 is fixed to the holder 100 such that the cutting edge 5 protrudes from the front end of the hold...

no. 2 approach

[0066] Next, use Figure 7 ~ Figure 12 , the insert according to the second embodiment of the present invention will be described in detail. It should be noted that, in Figure 7 ~ Figure 12 , for the above Figure 1 to Figure 6The same components are assigned the same symbols, and explanations thereof are omitted.

[0067] Such as Figure 7 ~ Figure 9 and Figure 12 As shown, the cutting tool 20' of this embodiment has: an upper contact portion 21'a composed of the upper surface 2' of the insert 1' and the opposing surface of the upper flange portion 101' of the toolholder 100'; The lower contact portion 21'b is constituted by the opposing surface of the lower surface 3' of the insert 1' and the lower flange portion 102' of the holder 100'.

[0068] Such as Figure 10 As shown in (a), the upper contact portion 21'a has a second concave-convex surface 23' on the upper flange portion 101' of the holder 100', and has a first concave-convex surface 22' on the upper surface ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap