Multi-purpose pipe bending mould

A versatile and bending technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as trouble changing molds, and achieve the effect of reducing mold manufacturing, unifying design standards, and reducing mold costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

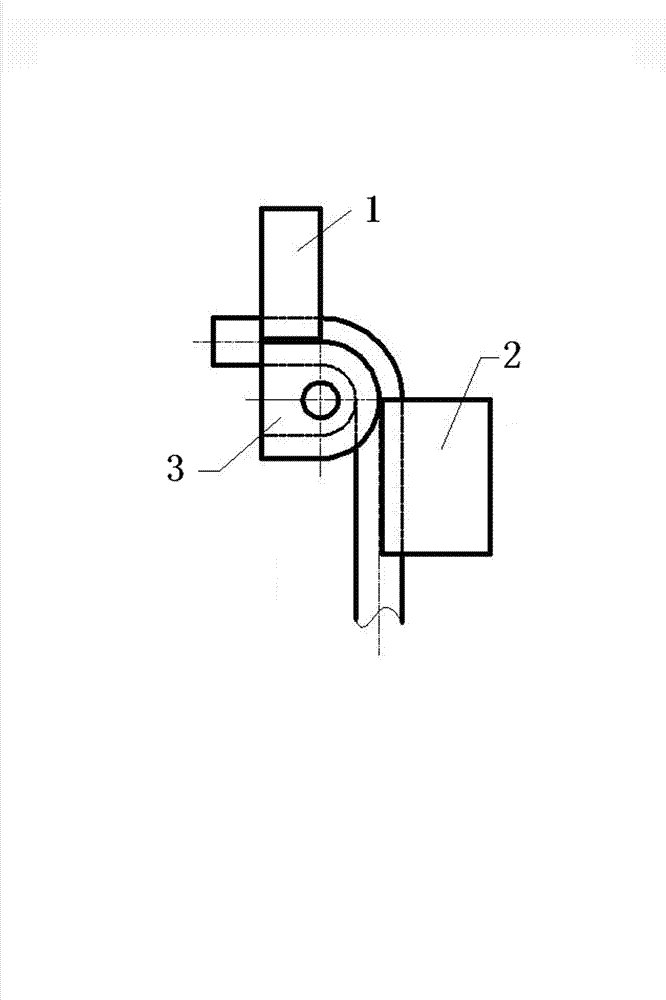

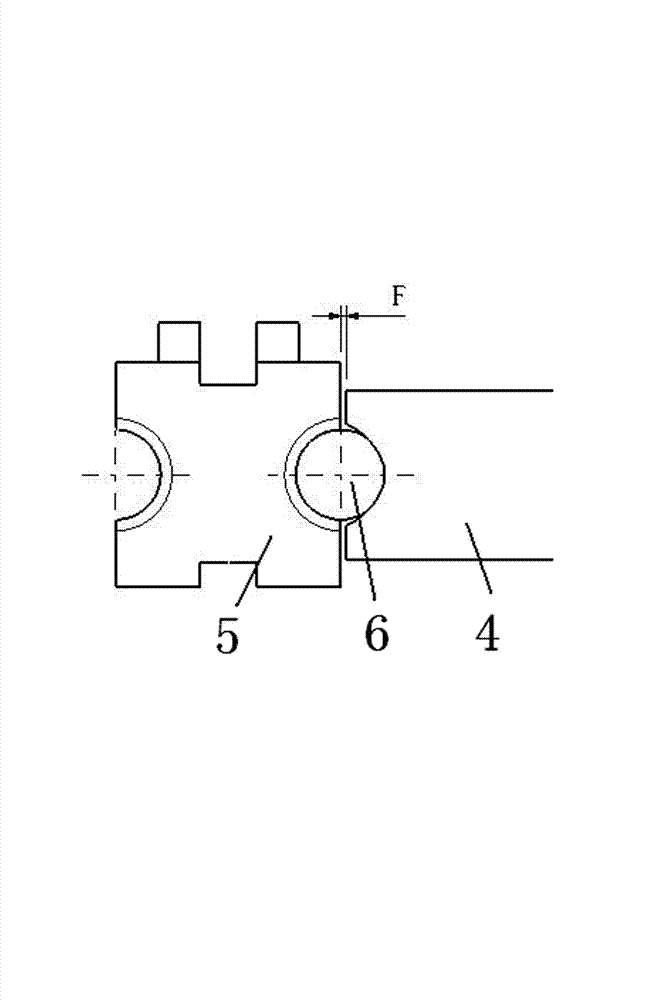

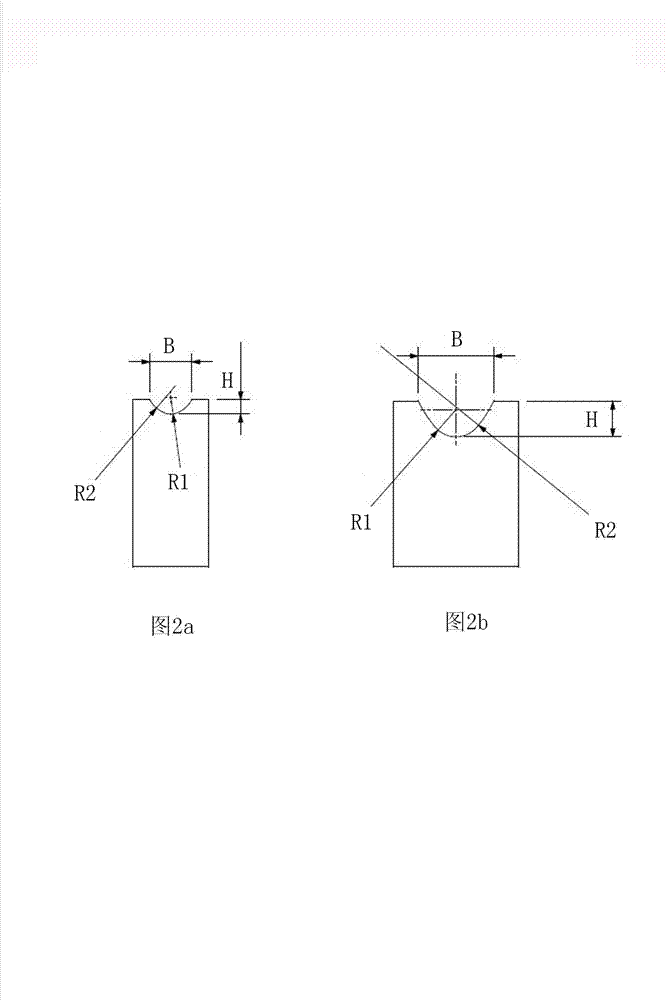

[0009] like figure 2 As shown, a multi-purpose bending pipe mold includes a fixed mold 5, a movable mold 4 and a guide plate (not shown in the figure) matched with the fixed mold 5, and is characterized in that one end of the movable mold 4 is provided with a special-shaped processing groove , the special-shaped processing groove is formed by connecting two arc surfaces with different radii. R2, where R2>R1, smooth connection between the first arc surface and the second arc surface (tangential connection between the first arc surface and the second arc surface), the stent is opened with the special shape The processing groove matches the semicircular processing groove, and the radius of the processing groove depends on the pipe diameter. According to a preferred embodiment of the present invention, the radius R1 of the first arc surface is 4-8mm, the radius R2 of the second arc surface is 6-30mm, the depth H of the processing groove is 3-10mm, and the width of the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com