Continuous casting tundish and continuous casting tundish casting control method

A continuous casting tundish and control method technology, applied in the field of tundish, can solve the problems of unfavorable tundish flow field improvement, reduction of molten steel residence time, large amount of residual steel in tundish, etc., to prolong average residence time, reduce The effect of stopping casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

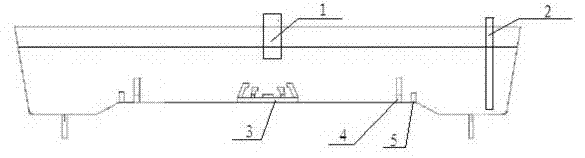

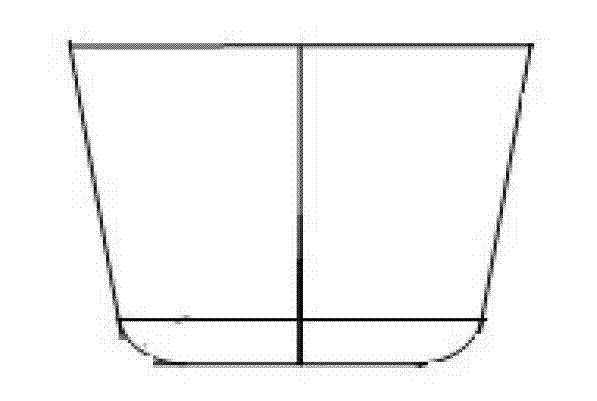

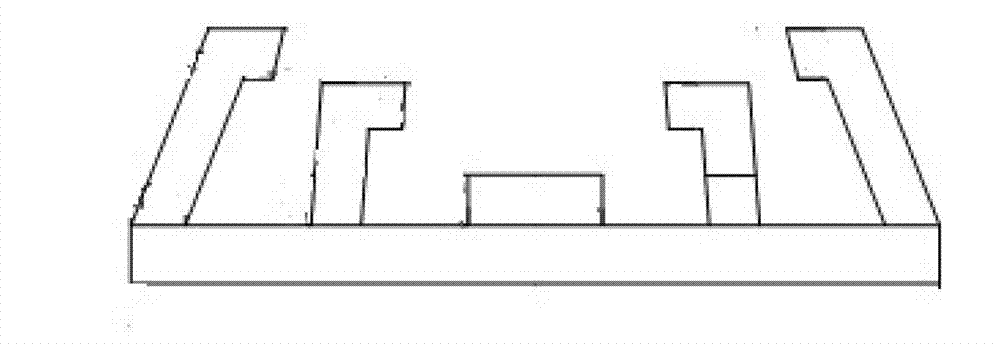

[0028] see Figure 1-4 , a continuous casting tundish provided by an embodiment of the present invention, which includes a two-strand slab continuous casting tundish, and further includes a tundish, a shroud 1, a stopper rod 2, a flow stabilizer 3 and a double retaining wall flow control device. Wherein, the shroud 1 is fixed on the bag body. The stopper rod 2 is fixed on the bag body. The flow stabilizer 3 is located below the shroud 1 . The flow stabilizer 3 is circular with eaves, and there is a double-layer turbulence controller with an inner ring inside. The double retaining wall flow control device is located between the shroud 1 and the stopper rod 2 . The double retaining wall flow control device includes a lower retaining wall 4 and a small retaining dam 5 . Have two apertures on the lower retaining wall 4. Small retaining dam 5 is positioned at lower retaining wall 4 rear sides, and height is slightly higher than the height of the hole that lower retaining wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com