A stretching method and its mold for adjusting the injection molding film in a mold by controlling the timing of glue feeding

A technology of timing adjustment and in-mold injection molding, which is applied in the field of in-mold injection molding, can solve problems such as creases in the in-mold injection molding process, and achieve a practical structural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

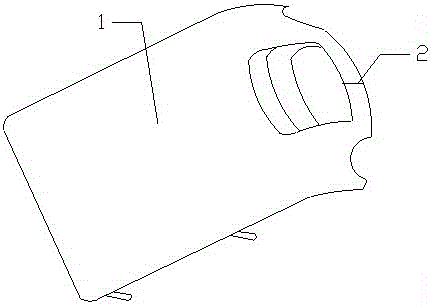

[0020] figure 1 It is a schematic diagram of the product implemented according to this plan. It is equipped with the main glue point 1 and the narrow side 2 structure of the workpiece; Crease; Narrow side 2 corresponds to the secondary glue point 5 set for adjusting the position of the joint line.

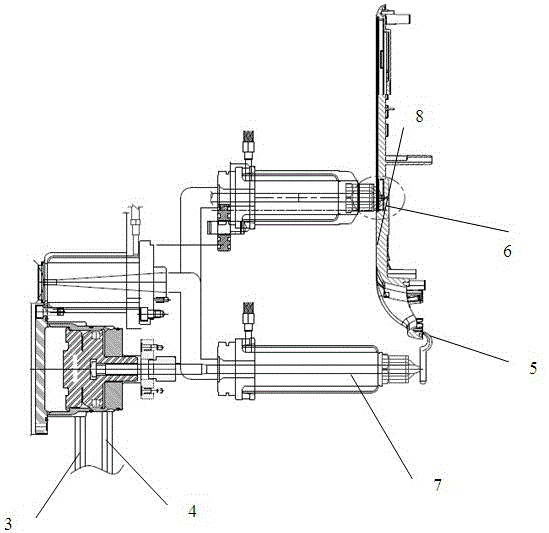

[0021] figure 2 It is a schematic diagram of the mold structure design, including secondary glue point 5 (smaller than the main glue point), main glue point 6, secondary glue point hot runner valve needle 7, main glue point hot runner valve needle 8, air pressure inlet and outlet pipes (3,4).

[0022] The specific steps of controlling the timing of glue feeding to adjust the stretching method of the in-mold injection molding film are as follows:

[0023] 1) Connect the timing controller with the injection signal of the injection machine to conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com