Suspension type wool material separation method

A technology of suspension and woolen material, which is applied in the field of suspension separation, can solve the problems that the unfolding effect of the fabric is not the best and the unfolding effect is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

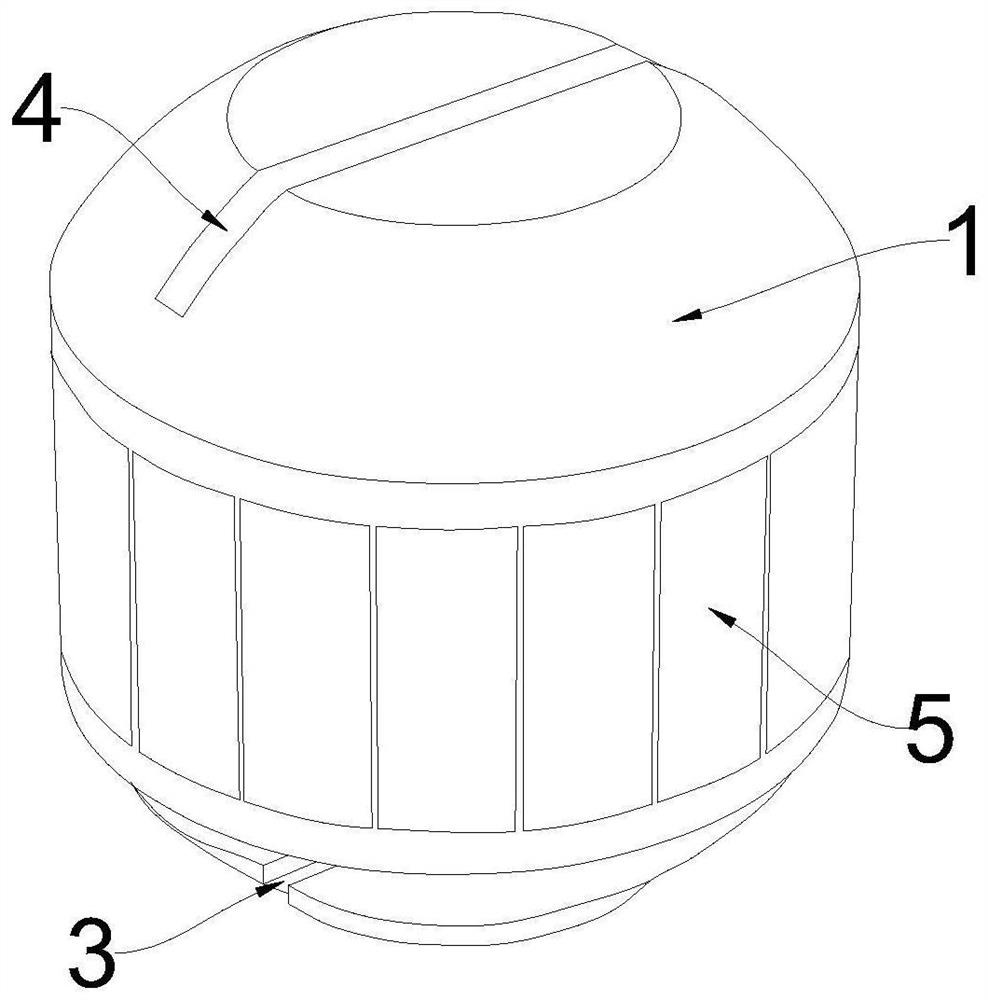

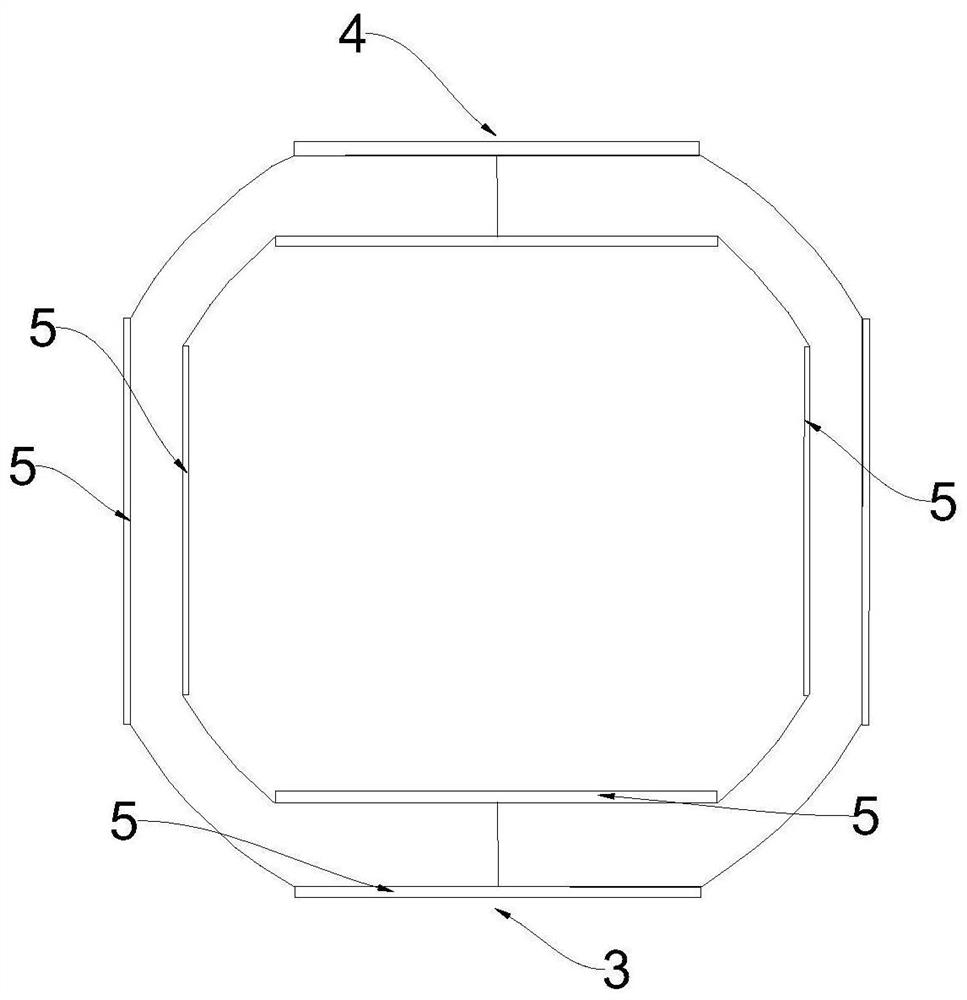

[0019] see figure 1 and figure 2 , Suspension separation method, the levitation body maintains the levitation state by means of magnetic levitation, in order to achieve the effect of magnetic levitation, a magnetic levitation mechanism is designed. The magnetic levitation mechanism includes a housing 1 and a suspension 2. One end of the housing 1 is provided with an inlet 3, and the other end is provided with an outlet 4. The housing is equipped with a first permanent magnet group, and the suspension is equipped with a second permanent magnet group. The first permanent magnet group and the second permanent magnet group are composed of several magnet pieces 5 respectively. The magnet pieces 5 in the first permanent magnet group are distributed around and at the bottom of the casing 1, and the magnet pieces 5 in the second permanent magnet group are distributed on the suspension. Around and at the bottom of the body 2, the magnet pieces 5 in the first permanent magnet group co...

Embodiment 2

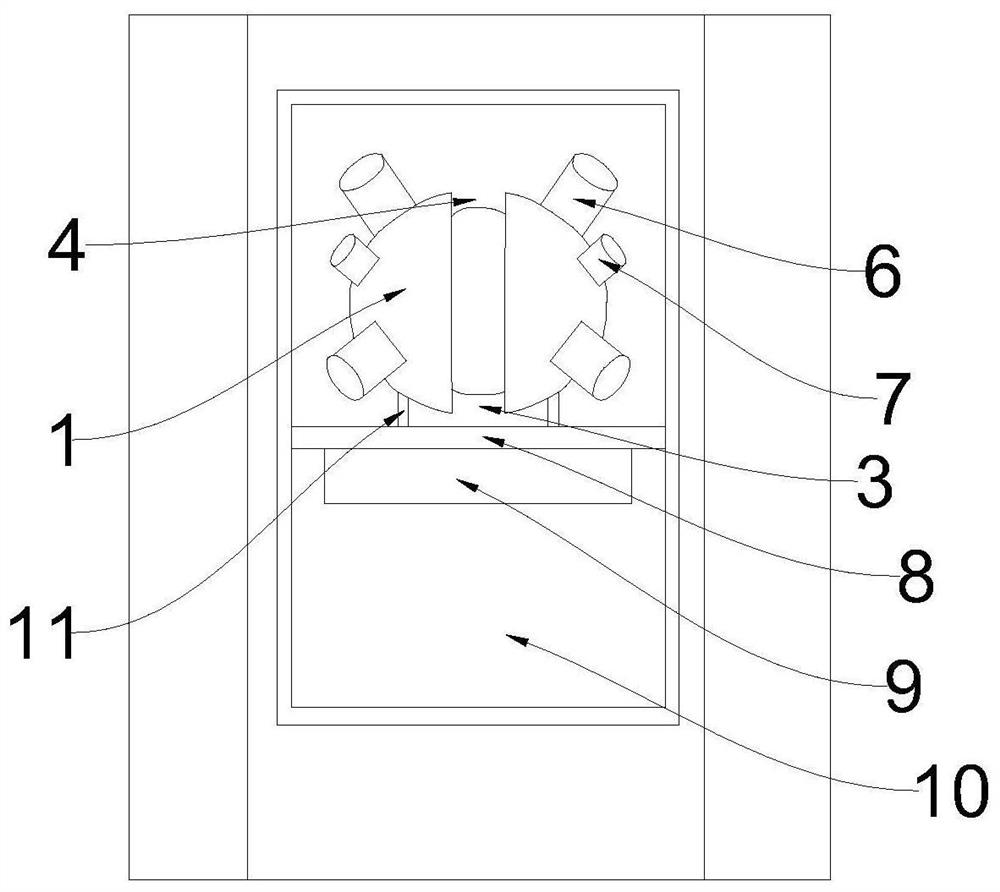

[0023] refer to image 3 , Suspension separation method, the suspending body maintains the suspended state by means of electromagnetic levitation, in order to achieve the effect of electromagnetic levitation, an electromagnetic levitation mechanism is designed. The electromagnetic levitation mechanism includes 8 electromagnetic coils 6, 4 permanent magnets 7, a casing 1, and a suspension body 2. The suspension body 2 is an iron ball, and the suspension ball 4 is a pure iron sphere, which can be magnetized to achieve levitation. The permanent magnet 7 on the shell 1 provides vertical support for the suspension ball 4 . The electromagnetic coil 6, the permanent magnet 7 and the iron ball constitute an electromagnetic levitation structure. The suspension separating device is installed in the shrinking machine. Shrinking machine comprises woolen sub-frame 8, sewage bucket 9, machine groove 10.

[0024] The shell 1 is in the shape of a drum as a whole, and the shell 1 includes a...

Embodiment 3

[0027] refer to Figure 4 , Suspension separation method, the suspension is maintained in a suspended state by means of air suspension, in order to achieve the effect of air suspension, an air suspension mechanism is designed. The air suspension mechanism includes a casing 1 and a suspension body 2 suspended in the casing 1. One end of the casing 1 is provided with an inlet, and the other end is provided with an outlet. The suspension 2 is an elastic inflatable ball, and the shell 1 is a sphere composed of a left hemisphere 12 and a right hemisphere 13. There is a gap between the left hemisphere 12 and the right hemisphere 13, and the left hemisphere 12 and the right hemisphere 13 are respectively installed on the support Rack 14. The shell 1 can also be a combination of cylindrical or spherical cylindrical shapes. The gap between the left hemisphere 12 and the right hemisphere 13 forms an inlet 3 at the lower end of the shell 1 and an outlet 4 at the upper end of the shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com