Semi-trailing full-load-bearing highway passenger vehicle body structure

A bus body structure and full load-carrying technology, which is applied to the upper structure of the bus, the upper structure, the motor vehicle, etc., can solve the problems that the driver is difficult to grasp the surrounding situation, the application of semi-trailer buses is reduced, and it is difficult to ensure the personnel in the car, etc. Achieve the effect of improving rollover safety, improving ride comfort and comfort, and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is further described in conjunction with accompanying drawing:

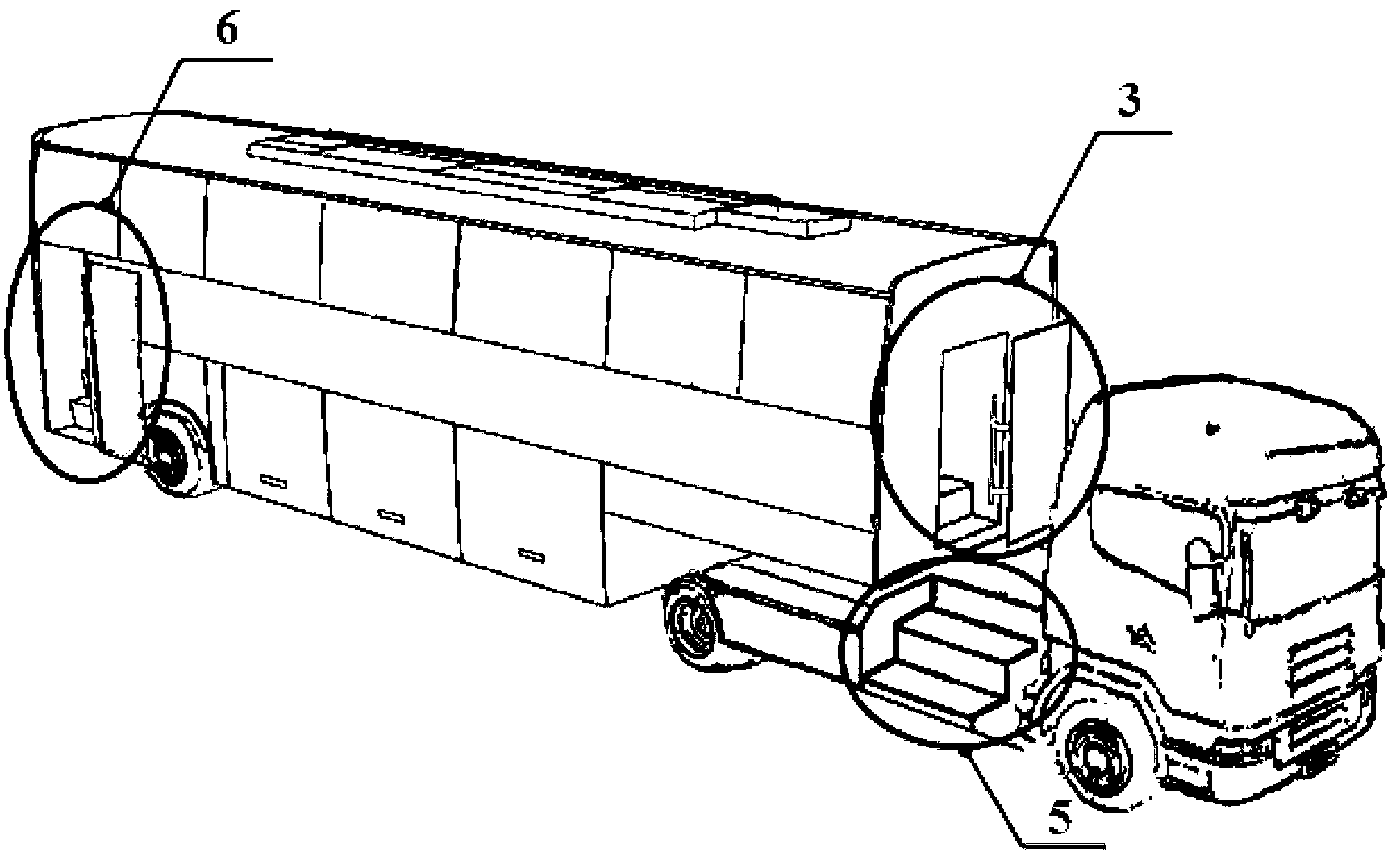

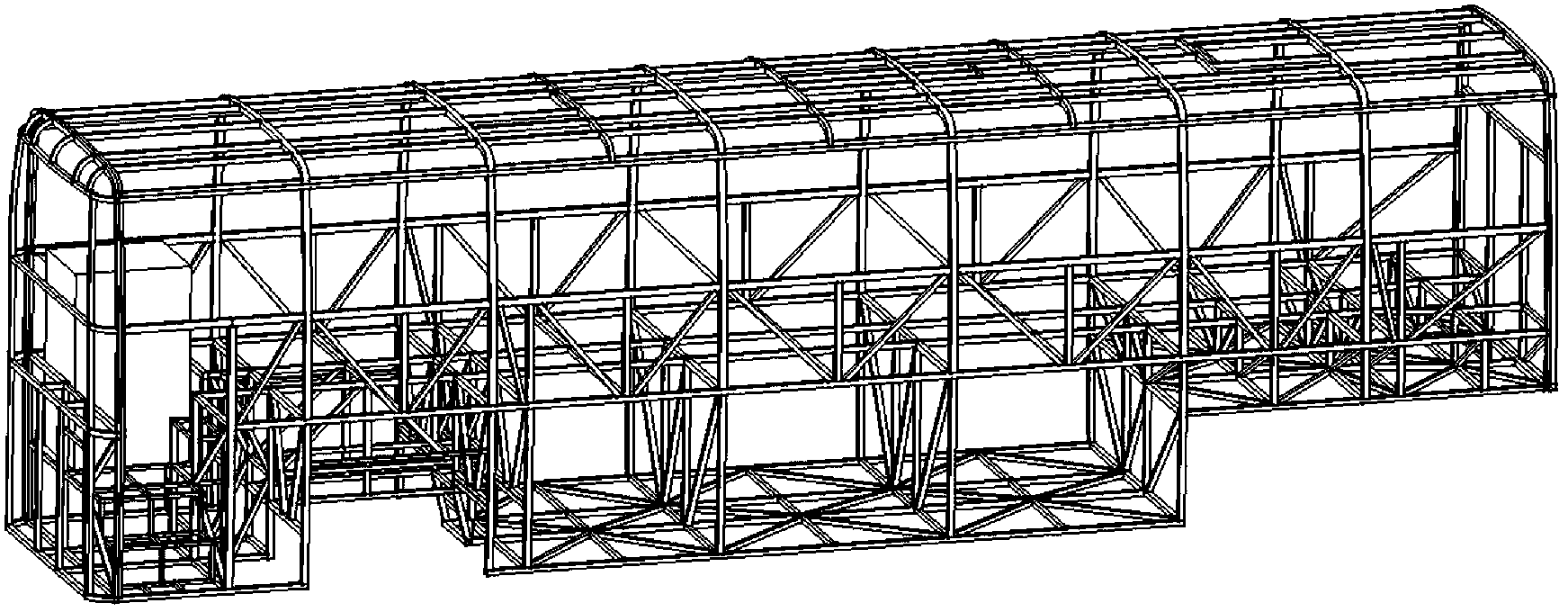

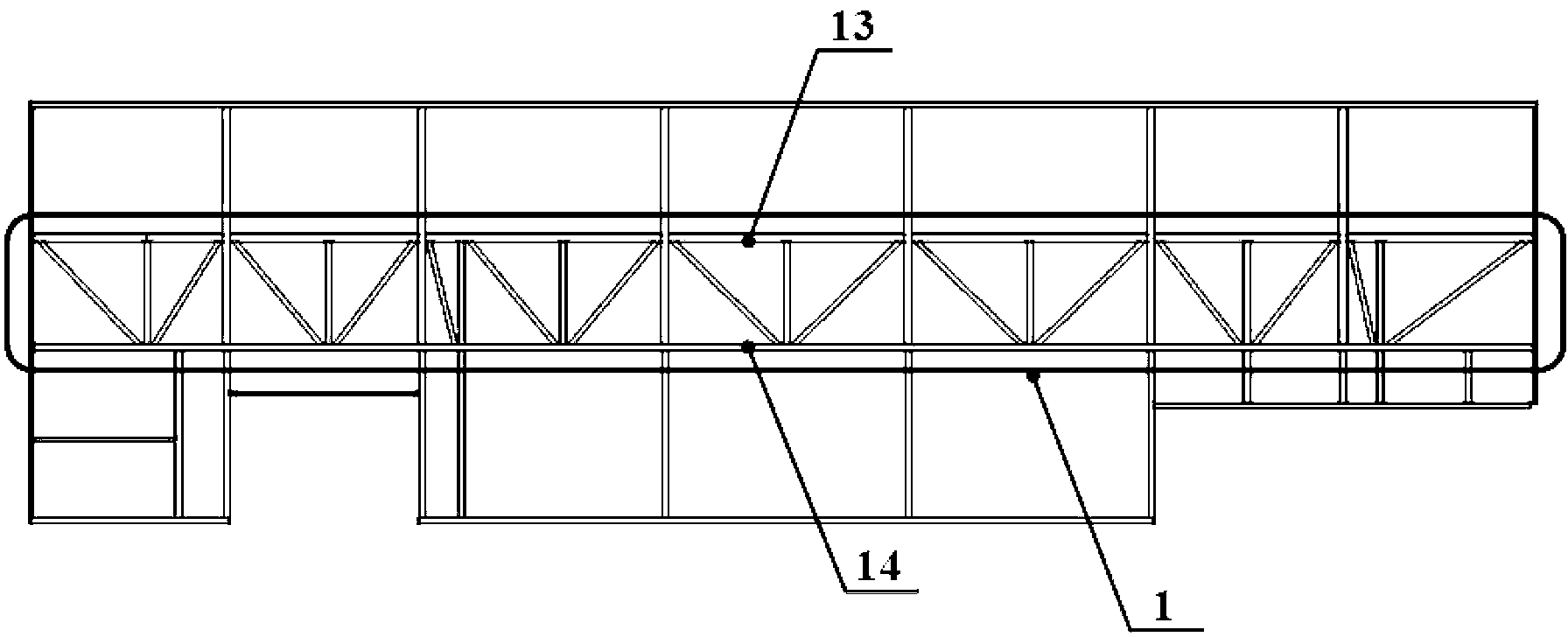

[0025] The body structure of the semi-trailer full load passenger car proposed in this scheme, the overall skeleton is as follows figure 2 , Figure 5 As shown, the whole is tailor-welded with small cross-section rods. The bearing section 1 on the left side of the vehicle body and the bearing section 2 on the right side maintain a frame structure with diagonal bracing that is completely connected, so that the vehicle body has a strong bearing capacity, such as image 3 , Figure 4 shown.

[0026] The joint parts of the body and the traction frame and the front part of the rear suspension of the body adopt such as Figure 5 The double-section support structure shown in 11 and 12 can effectively improve the structural strength of the key load-bearing parts of the body structure. The double-section structure design should include at least one complete clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com