Self-locking composite conducting wire hoisting hook

A technology of lifting hooks and multiple wires, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of not being on the same straight line, the lower wires are easy to fall off, and the center of gravity of the hook is shifted, so as to increase the working time, Improving efficiency and professional level, the effect of locking firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

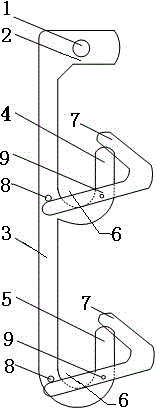

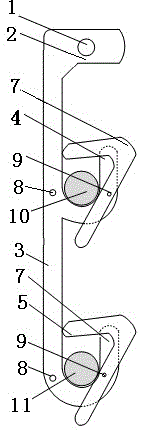

[0014] Such as figure 1 and figure 2 As shown, a self-locking double wire lifting hook includes a suspension ring 1 and a wire hook, and the suspension ring 1 is arranged on a beam 2; The hook 5 is connected with the crossbeam 2 through the connecting rod 3; the crossbeam 2 and the connecting rod 3 are vertically arranged; the upper wire hook 4 and the lower wire hook 5 are respectively connected with the connecting rod 3 to form a U-shaped accommodation structure 6 for accommodating the wire; The center of the suspension ring 1 is located on the same straight line as the center of the U-shaped accommodation structure 6 of the upper wire hook and the lower wire hook; the U-shaped accommodation structure 6 is provided with a self-locking mechanism for preventing the wire from falling off. The self-locking mechanism includes a "7-shaped" self-locking rod 7 and a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com