Yarn feeder and yarn brake

A technology of yarn brake and yarn supply, applied in textiles and papermaking, looms, knitting, etc., can solve problems such as uncontrollability and affecting braking effect, and achieve the effect of eliminating oscillation and maintaining yarn braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

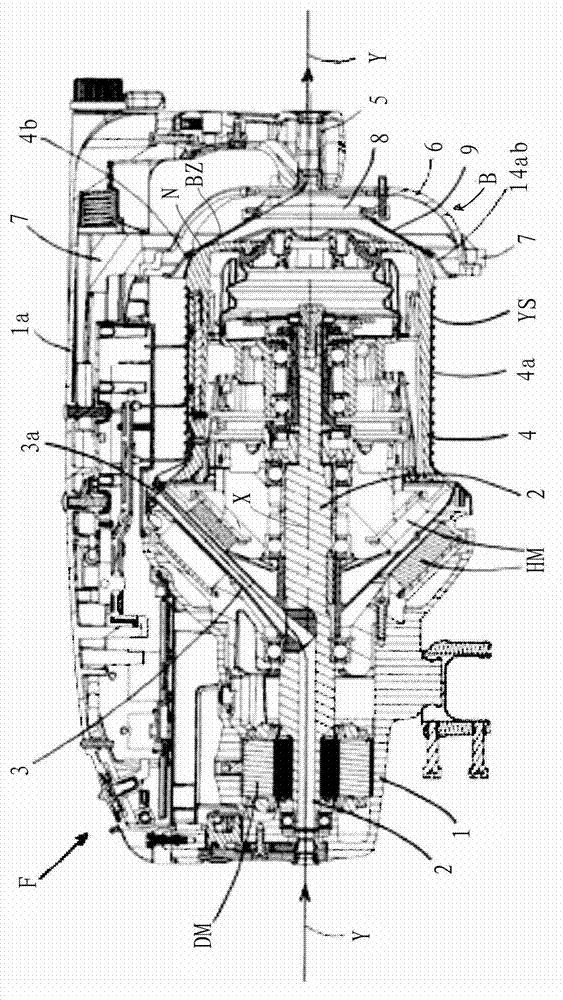

[0016] figure 1 A yarn feeder F with a stationary housing 1 is shown, comprising a drive motor DM for driving a central shaft 2 in rotation within the housing 1 . The upstream rear part of the shaft 2 is hollow and communicates with the yarn winding tube 3 extending obliquely outwards, the yarn winding tube 3 is fixed to the middle part of the shaft 2, and the yarn winding tube 3 rotates together with the shaft 2 . A storage body 4 is rotatably supported in front of the shaft 2 . The storage body 4 is prevented from co-rotating with the shaft 2 when the shaft 2 is driven, for example in cooperation with the permanent magnets HM arranged in the storage body 4 and the stationary housing 1 respectively. The storage body 4 defines a substantially cylindrical storage surface 4a and has an axis X. As shown in FIG. The storage surface 4a serves to support a schematically shown temporary yarn storage YS formed from a plurality of coils of yarn Y wound continuously. For example, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com