Transmission mechanism of electric-control electrocar door

An electronically controlled electric vehicle and electric vehicle technology, applied in the direction of power control mechanism, wing leaf control mechanism, door/window accessories, etc., can solve the problems of slow closing speed and complicated locking action alone, and achieve small friction angle, Reduced maintenance cost, large lead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

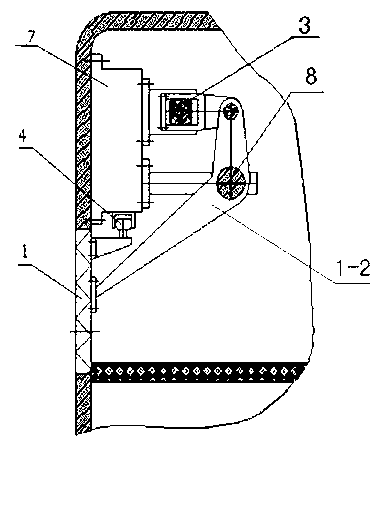

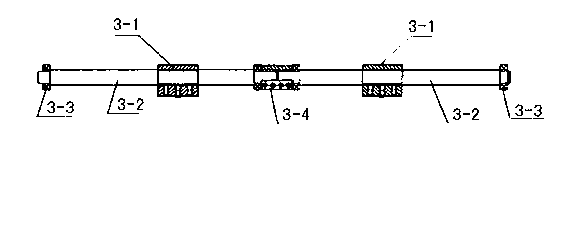

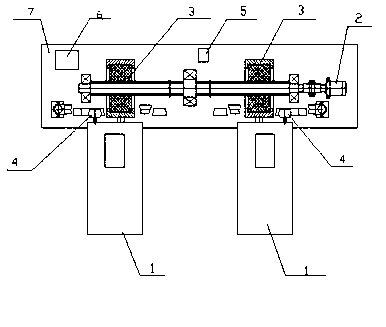

[0013] Depend on figure 1 , figure 2 Known, a transmission mechanism of an electronically controlled electric car door includes a door system 1 and a door head mechanism 7. The car door system 1 is composed of two left and right door leaves 1-1 and a shift fork 1-2, and the door head mechanism 7 is located on the door leaf 1-1. Above 1, the door head mechanism 7 is equipped with a driving mechanism 2, a transmission device 3, a guiding mechanism 4, a locking device 5 and a door control unit (DCU) 6. The driving mechanism 2 is composed of a motor and a coupling; the transmission device 3 is composed of a combined screw, a nut and three support seats; the door control unit (DCU) 6 issues instructions, the motor drives the screw to rotate, and the upper side of the door leaf is connected with a dial Fork 1-2, the shift fork is a connecting rod structure, connected with the variable diameter combination nut through the bearing shaft 8 installed in the door head mechanism, the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com