Construction method for three-dimensional intersection concave-convex fulcrums

A construction method and fulcrum technology, applied in the direction of earth cube drilling, mining equipment, tunnels, etc., can solve the problems of large dust, large amount of reinforced concrete demolition, high risk, etc., and achieve simple process flow, large economic benefits, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

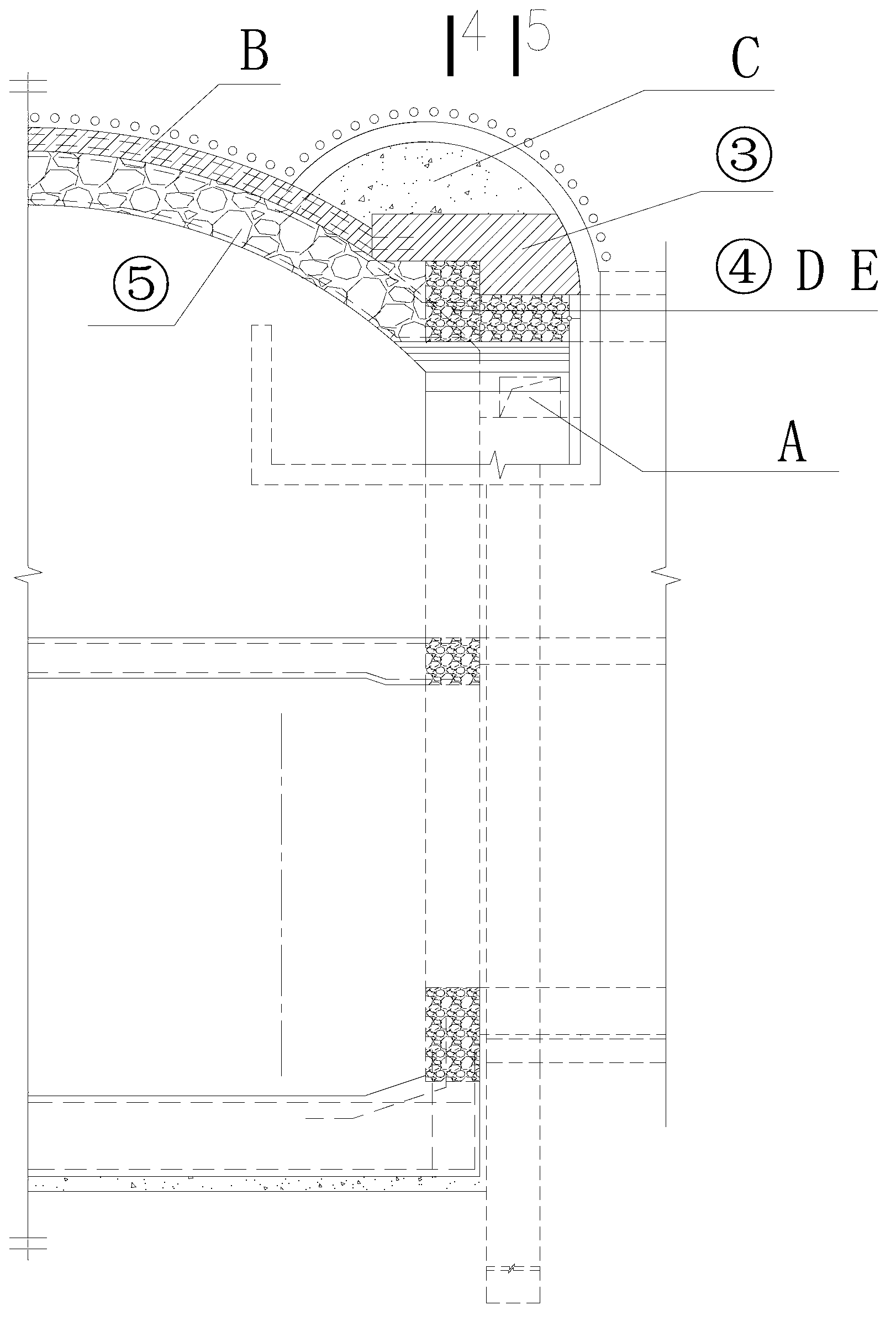

[0027] Such as Figure 1-5 As shown, the construction method of the cross concave-convex fulcrum described in the embodiment of the present invention includes the following steps:

[0028] 1. Construction of protective piles: 1) Pile position layout. For the piles on both sides other than the air duct structure (not to be demolished), there is a margin of 5cm between the side of the pile and the side of the second lining structure. The distance between the ~3 piles should be properly intensified; for the piles within the air duct structure (need to be removed), the distance between the piles should be increased appropriately. (The pile arrangement method is applicable to all opening intersection structures). 2) Construction of retaining piles. Holes are formed by mechanical or excavated piles, depending on the design and site conditions, and constructed according to norms and mature practices; within the scope of the reserved holes that need to be broken, the piles are fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com