Engine

An engine and tight ring technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of not preventing the valve stem and valve guide from accelerated wear and valve hovering, manual removal, and the engine cannot automatically remove the valve stem. Carbon and other issues can be reduced to reduce valve hovering and reduce accelerated wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

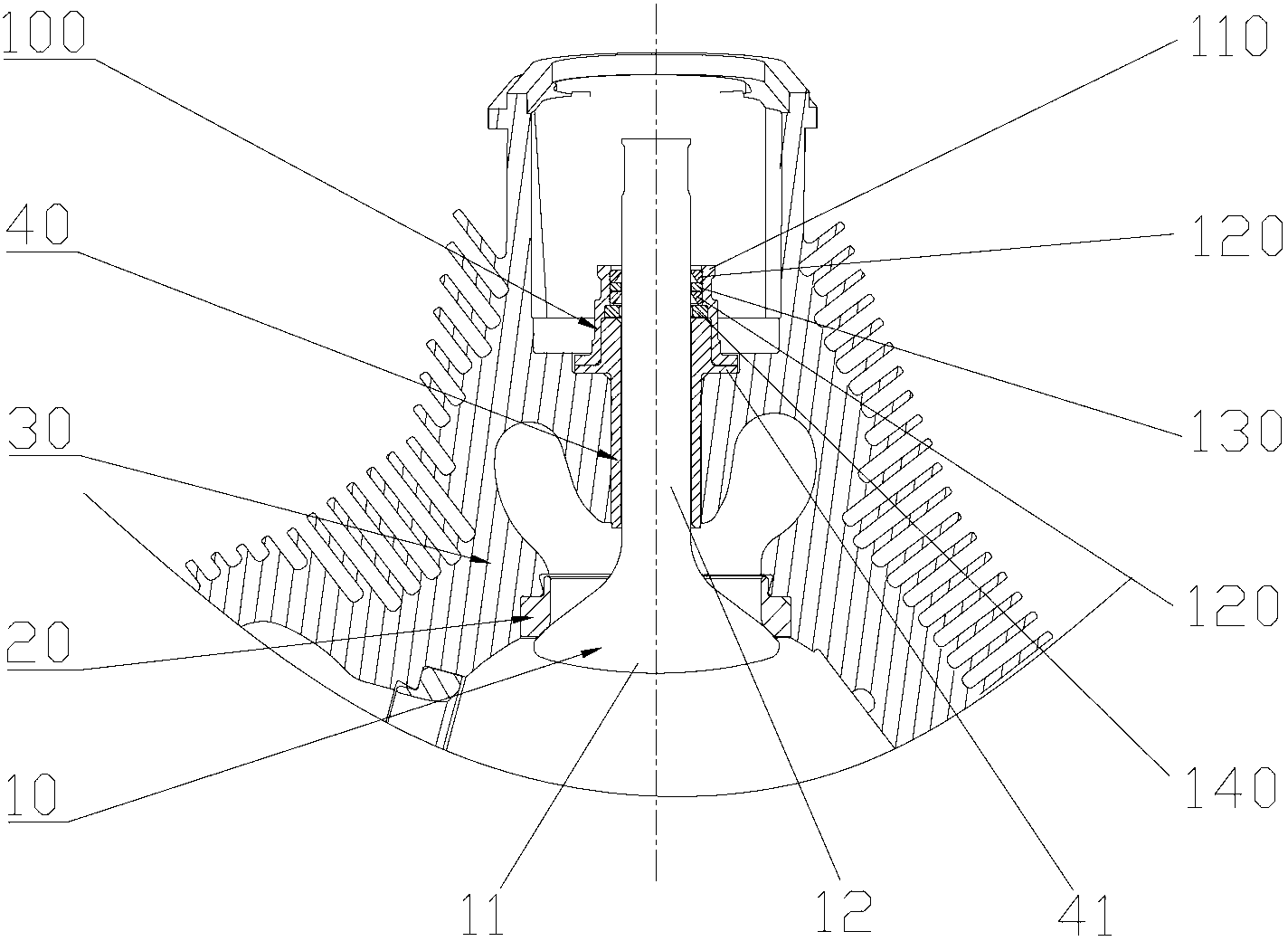

[0033] figure 1 It is a schematic diagram of the matching structure of the valve stem carbon scraping device, the valve and the valve guide of the engine according to an embodiment of the present invention. in figure 1 In the figure, only the valve 10, the valve seat 20, a part of the body 30, the valve guide 40 and the valve stem carbon scraping device 100 are shown.

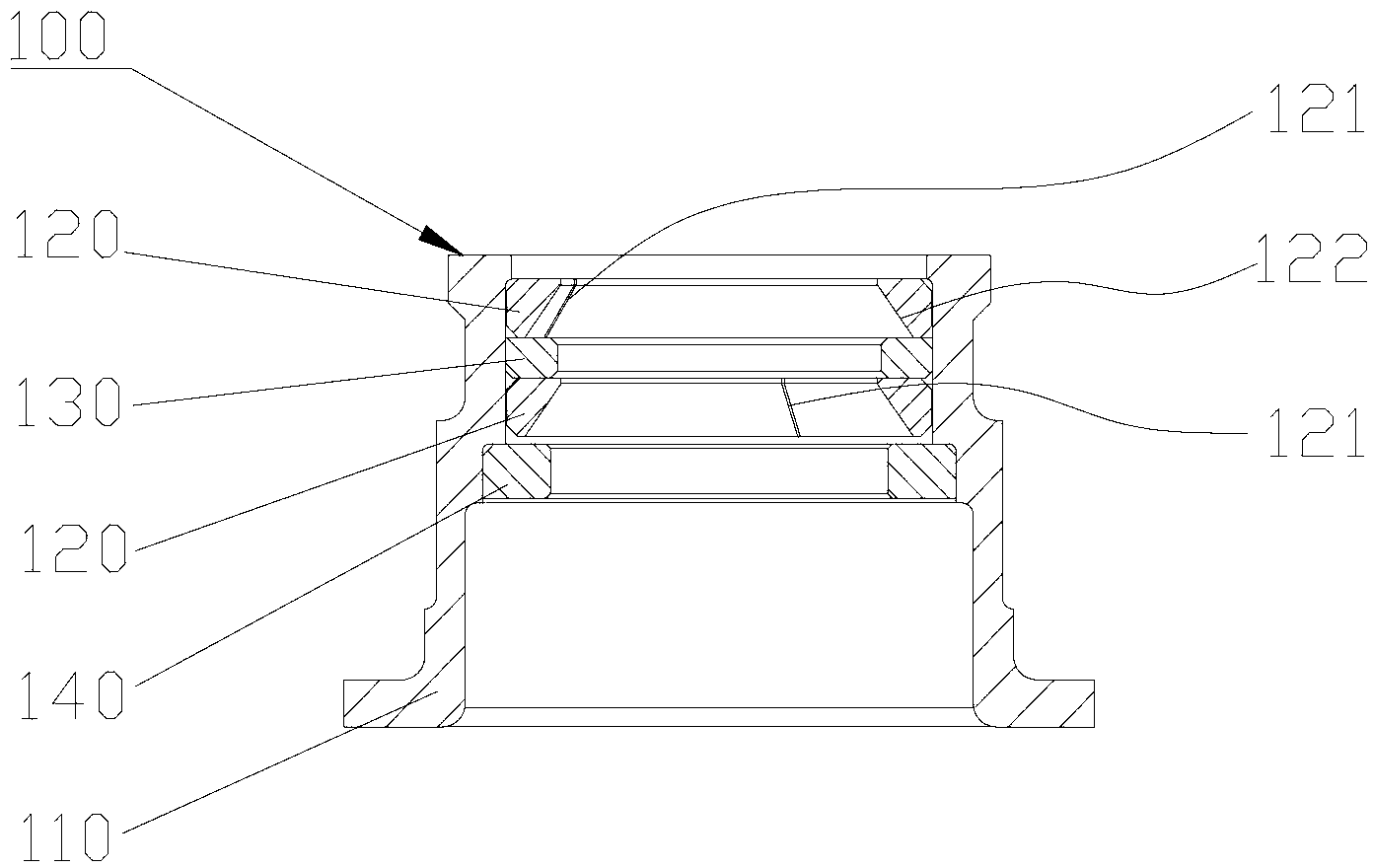

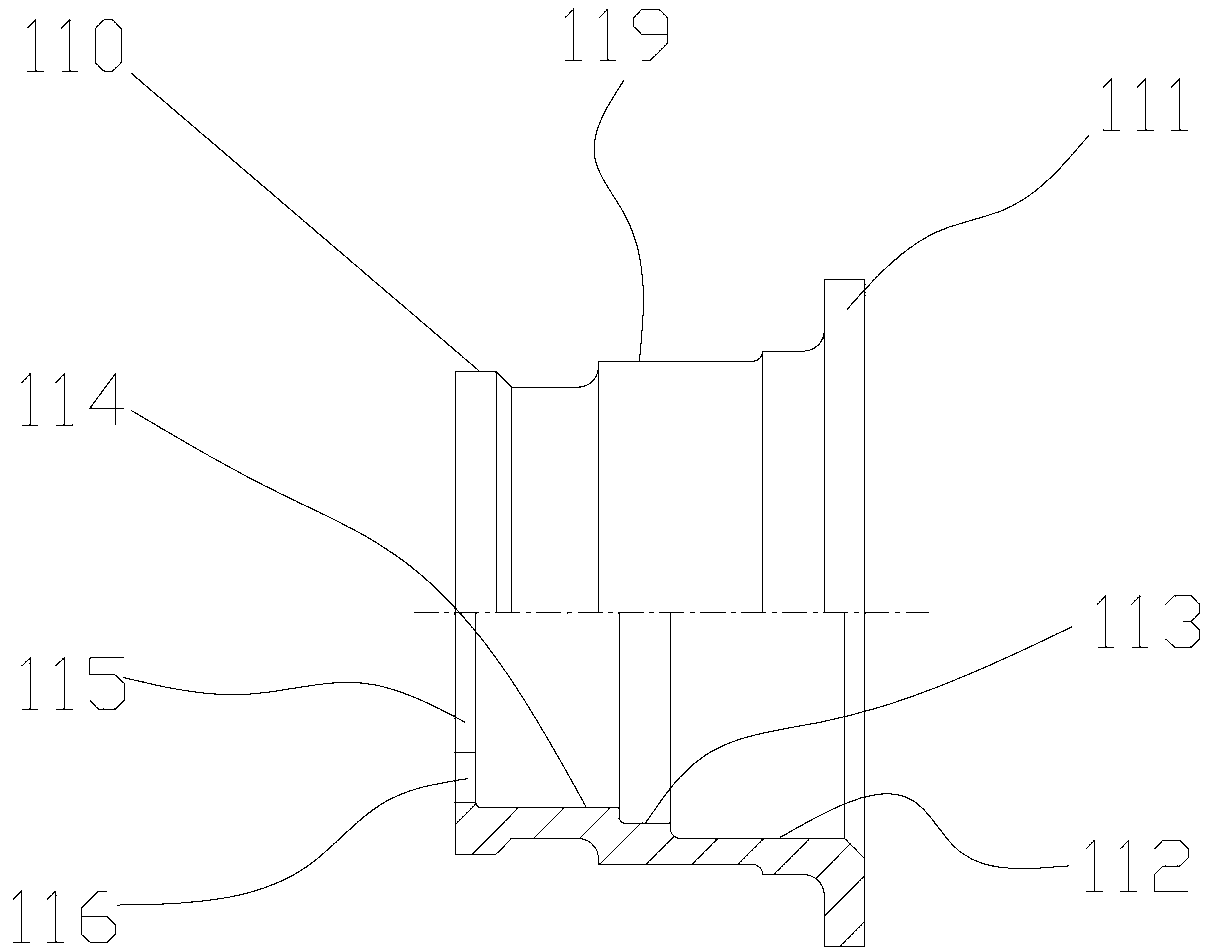

[0034] Such as figure 1 As shown, the engine of this embodiment includes a valve 10, a valve guide 40, and a valve stem carbon deposit scraping device 100. The valve 10 includes a head 11 and a valve stem 12 that is clearance fit with the valve guide 40. The valve stem carbon deposit scraping device 100 includes a rigid sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap