Dust collection type spherical stop valve

A cut-off valve, spherical technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of short service life, fragile sealing surface, not resistant to high pressure, etc., to achieve improved performance, small rotational friction, Good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

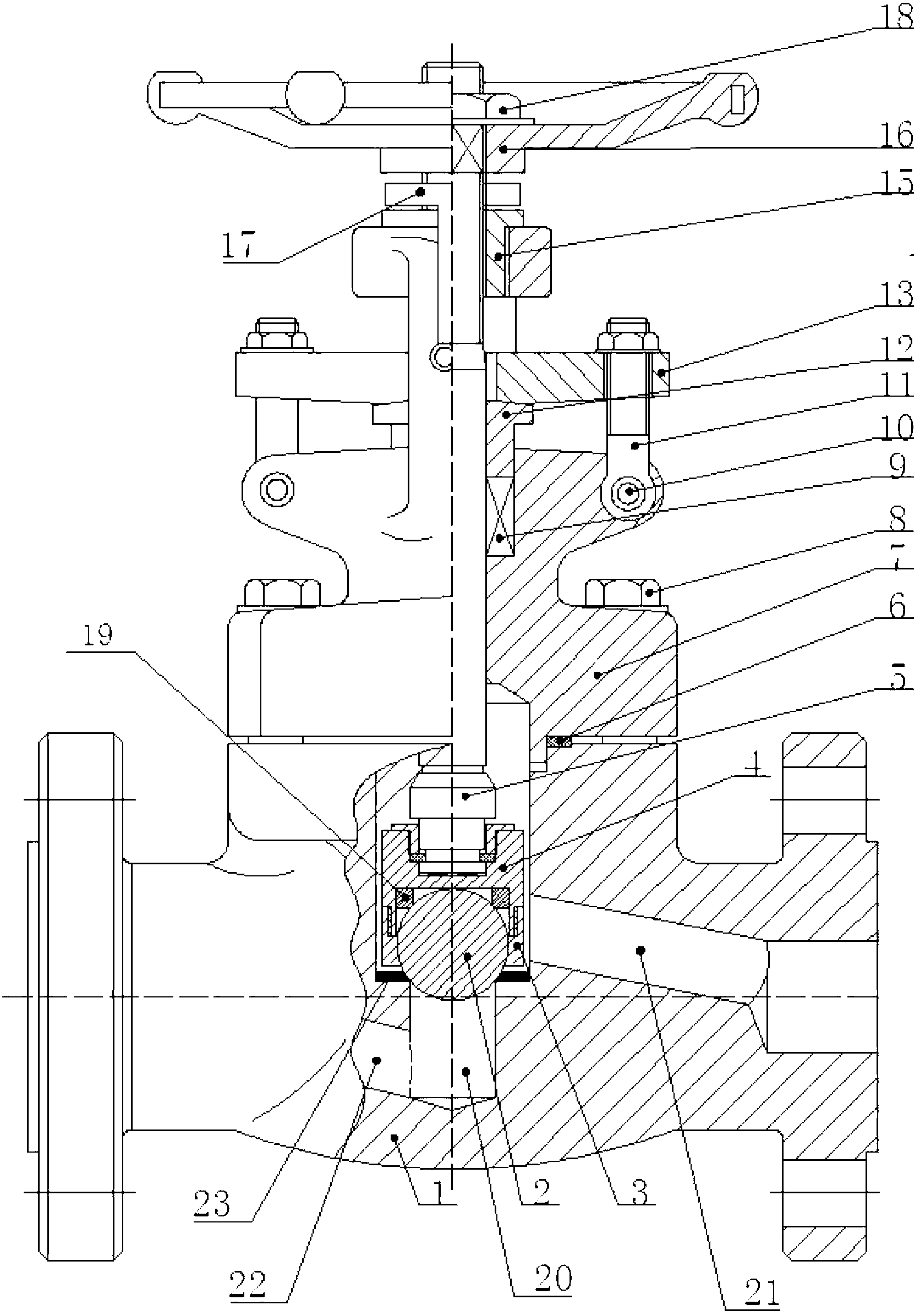

[0015] Such as figure 1 As shown, the present invention provides a dust-removing spherical globe valve, including a valve body 1, a valve cover 7, a valve clack 4, a ball core assembly, a valve stem 5 and a handwheel 16, and the valve cover 7 and the valve body 1 are arranged between There is a middle gasket 6 and the middle bolts 8 are fixedly connected together. The valve body 1 is provided with a valve cavity 20. The left and right ends of the valve body 1 are provided with an inlet 22 and an outlet 21 communicating with the valve cavity 20; the valve disc 4 is arranged in the valve cavity 20, and one end of the valve disc 4 and the valve stem 5 The other end of the valve stem 5 extends out of the valve cover 7 and is connected to the hand wheel 16, the hand wheel 16 is provided with a lock nut 18. The ball core assembly is arranged between the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com