Polarizers with optical films

An optical film and polarizer technology, applied in the optical field, can solve the problems of easy dust accumulation, high consumption of materials, and low polarizer life, and achieve the effects of good wear resistance, reducing fatigue and improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

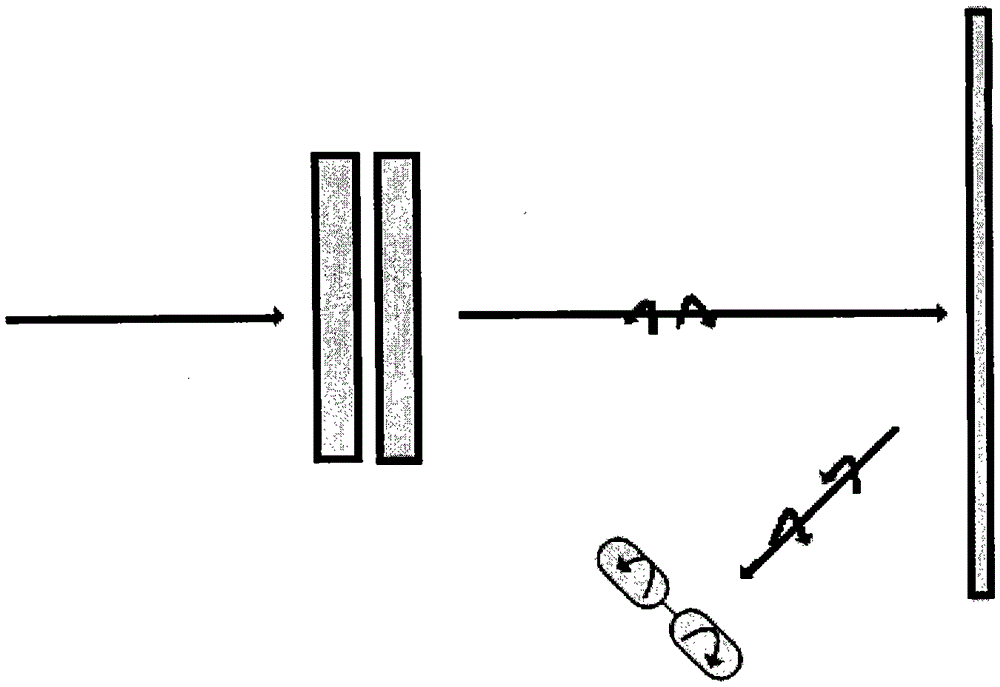

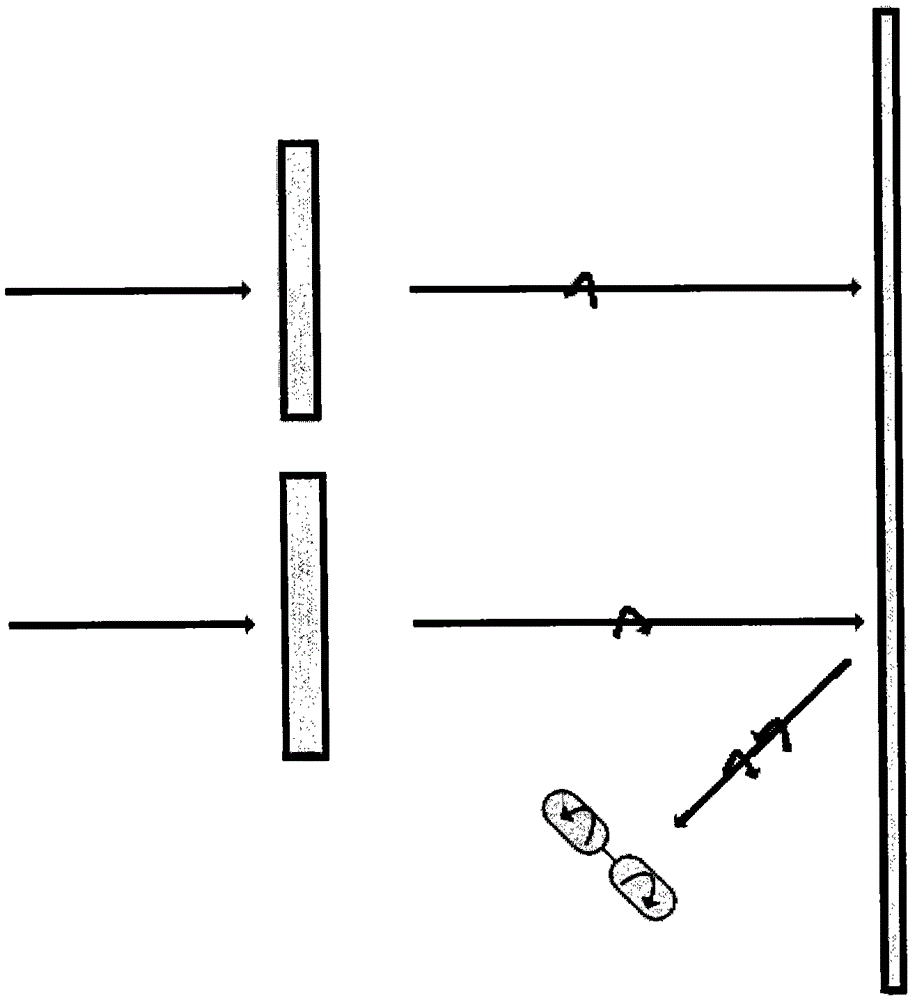

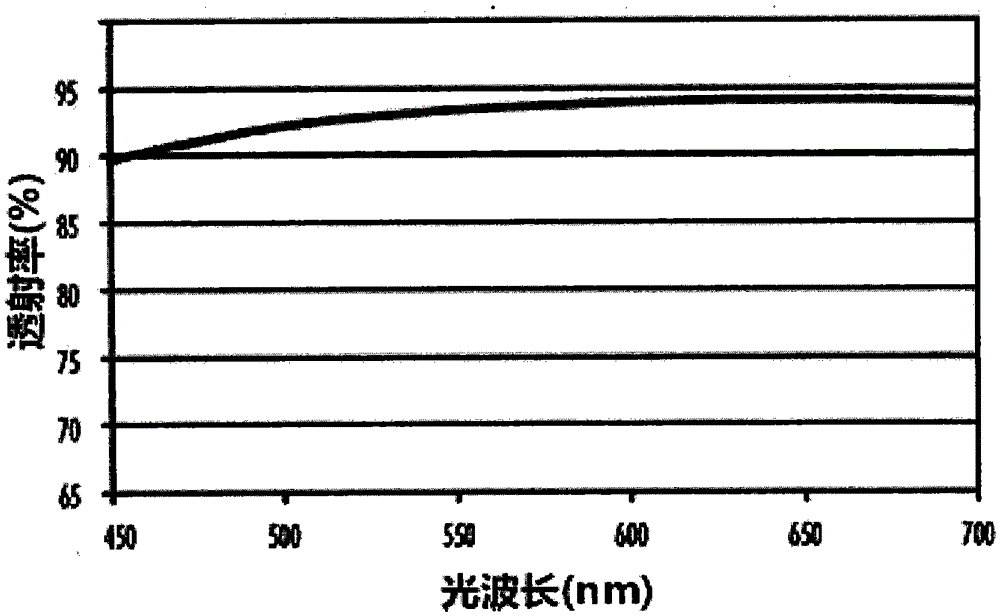

[0020] The polarizer with optical film according to the present invention, wherein boron-doped nano-ZnS is sequentially formed on the optical glass or optical resin polarizer substrate 1-X o X Thin films, composite metal films of nano-silver and copper, and nano-ZnO, TiO 2 and BaO nanocomposite oxide film. Wherein, the boron-doped nano-ZnS 1-X o X The film is prepared by a chemical vapor deposition method with a thickness of 25-50nm; the composite metal film of nano-silver and copper is prepared by an arc ion plating method with a thickness of 10-20nm, wherein the mass ratio of silver to copper is 2: 1-3:1; the nanocomposite oxide film is obtained by magnetron sputtering, with a thickness of 50-100nm. as attached image 3 As shown, in the polarizer with optical film according to the present invention, the transmittance of polarized light in the spectral range of 450-550nm is higher than 90%, and the transmittance of polarized light in the spectral range of 550-700nm is hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com