Dynamic grating for 2D-to-3D (two-dimension to three-dimension) conversion

A dynamic grating and 3D technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as narrow working temperature range of liquid crystal molecules, narrow viewing angle range, and complex devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

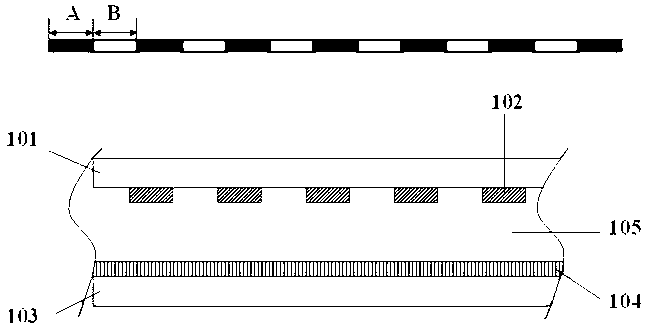

[0038] figure 1 It is an electrochromic dynamic grating that can be used for 2D / 3D conversion provided by the embodiment of the present invention. It is characterized in that it includes a first control layer, a second control layer, a grating material layer and a control module. In this embodiment, The grating material layer is an electrochromic material layer.

[0039] The first control layer includes: a first transparent substrate 101, a first transparent electrode 102; in this embodiment, the first transparent electrodes can be strip-shaped, sawtooth-shaped or stepped, and the first transparent electrodes are spaced from each other and parallel to the lower surface of the first transparent substrate. The second control layer includes: a second transparent substrate 103 and a second transparent electrode 104; the second transparent electrode is a surface electrode and is arranged on the upper surface of the second transparent substrate. The electrochromic grating material...

Embodiment 2

[0046] Figure 4 It is a thermochromic dynamic grating that can be used for 2D / 3D conversion provided by the embodiment of the present invention. It is characterized in that it includes a first control layer, a second control layer, a grating material layer and a control module. In this embodiment, The grating material layer is a thermochromic material layer.

[0047] The first control layer includes: a first transparent substrate 201, and a first transparent electrode 202; the first transparent electrodes can be in the shape of strips, zigzags and steps, and are spaced from each other and arranged in parallel on the first transparent substrate lower surface. The second control layer includes: a second transparent substrate 203 and a second transparent electrode 204; the second transparent electrode is a surface electrode and is arranged on the upper surface of the second transparent substrate. The thermochromic grating material layer 205 is placed between the first control ...

Embodiment 3

[0053] Figure 5 It is a piezochromic dynamic grating and its control method that can be used for 2D / 3D conversion provided by the embodiment of the present invention. It is characterized in that it includes a first control layer, a second control layer, a grating material layer and a control module; In an embodiment, the grating material layer is a piezochromic material layer.

[0054] The first control layer includes: a first transparent substrate 301, and a first transparent electrode 302; the first transparent electrodes can be in the shape of strips, zigzags and steps, and are spaced from each other and arranged in parallel on the first transparent substrate lower surface. The second control layer includes: a second transparent substrate 303 and a second transparent electrode 304; the second transparent electrode is a surface electrode and is arranged on the upper surface of the second transparent substrate. The piezochromic grating material layer 305 is placed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com