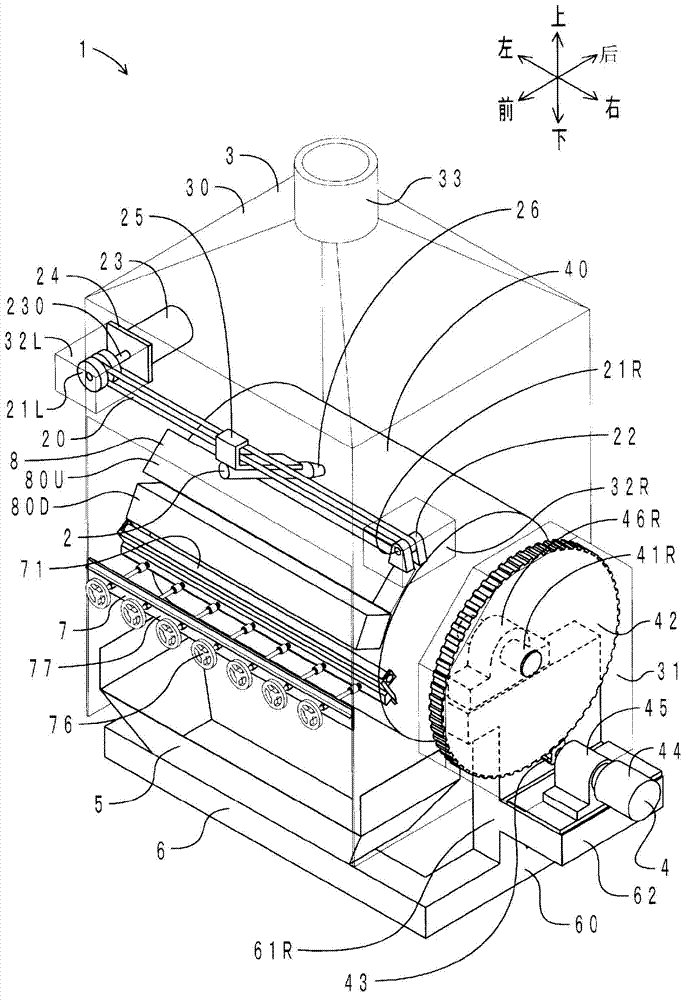

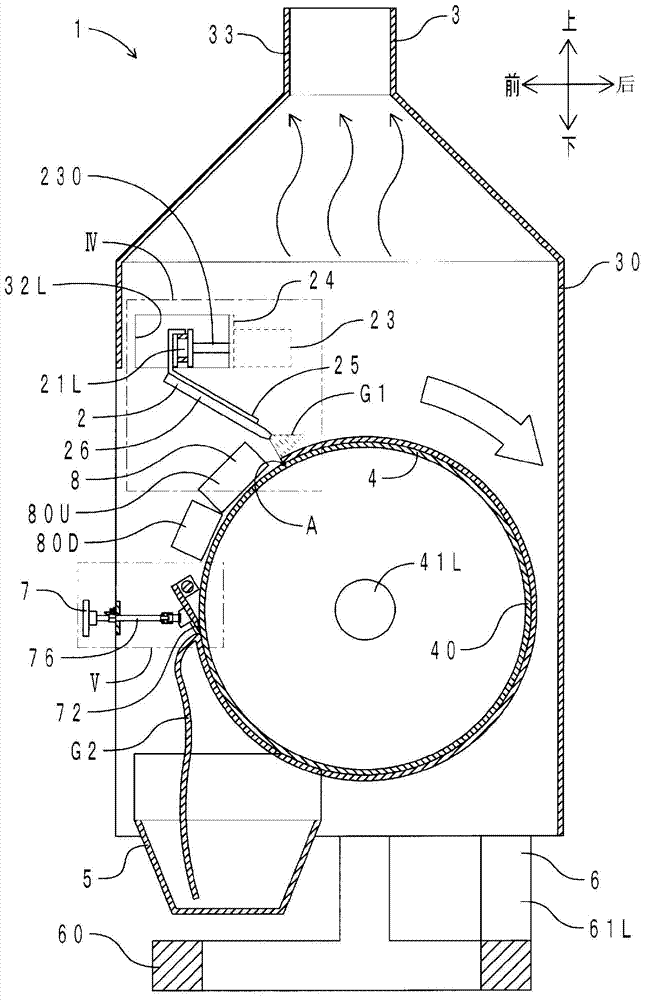

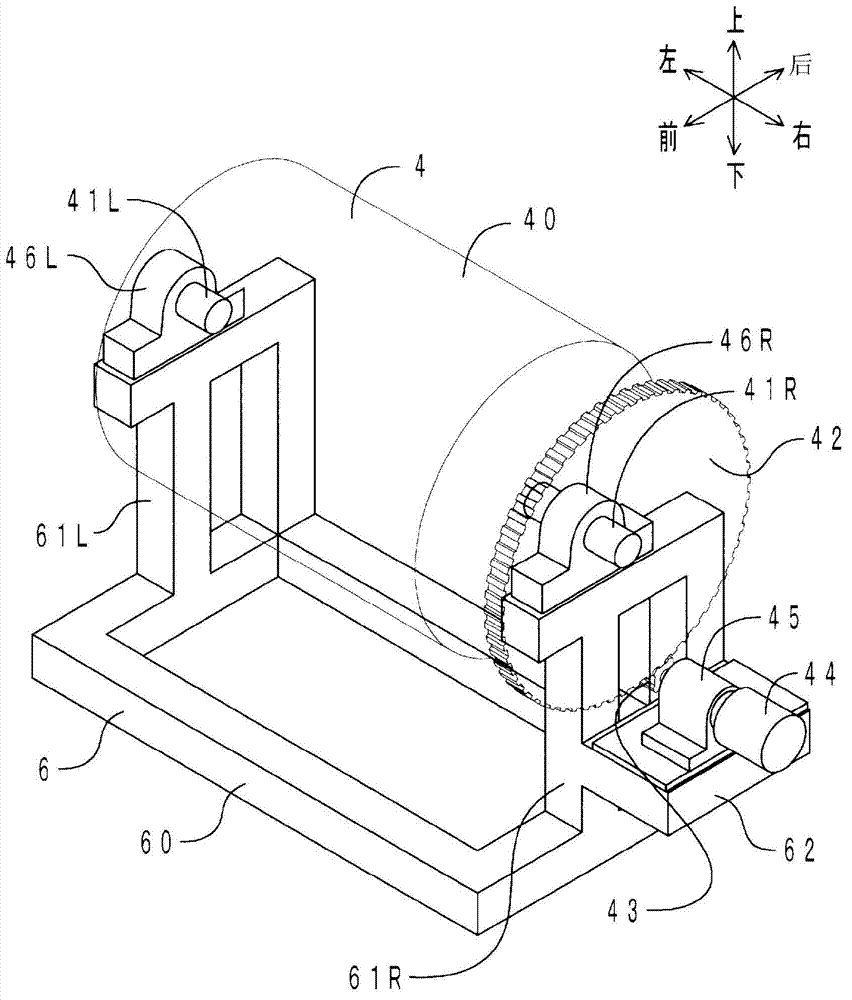

Solid natural rubber and method and device for producing same

A solid natural rubber and manufacturing device technology, applied in the field of solid natural rubber, can solve problems such as rubber viscosity deviation, and achieve the effects of shortening time, low cost, and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] The solid natural rubber produced by the manufacturing apparatus 1 of the above-mentioned embodiment was cross-linked, and its cross-linking properties were evaluated. First, 100 parts by mass of solid natural rubber, 2.5 parts by mass of sulfur, and 1 part by mass of N-cyclohexyl-2-benzothiazole sulfenamide ("NOCCELER" manufactured by OUCHI SHINKO CHEMICAL INDUSTRIAL CO., LTD. (registered trademark) CZ-G"), 5 parts by mass of zinc oxide (the zinc oxide is zinc oxide type 2 according to JIS K1410) and 1 part by mass of stearic acid were kneaded to prepare a rubber composition. Two types of rubber compositions were prepared using two types of solid natural rubbers produced in different batches as the solid natural rubber (Example 1 and Example 2). Next, the prepared two rubber compositions were crosslinked at a temperature of 150° C., and the crosslinking speed and the like were measured. Measurements were carried out in accordance with JIS K6300-2 (2001) using a rotorl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com