Method for welding large-size tantalum strips

A welding method and large-scale technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as inability to weld tantalum bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First cut off the cracked part of the diamond-shaped tantalum bar with a side length of 4×4mm to ensure that the broken end of the tantalum bar is free of cracks, hollows and black centers. Strictly remove oil and other pollutants within 30mm of the welding part, and wipe with alcohol to ensure that the welding area is clean.

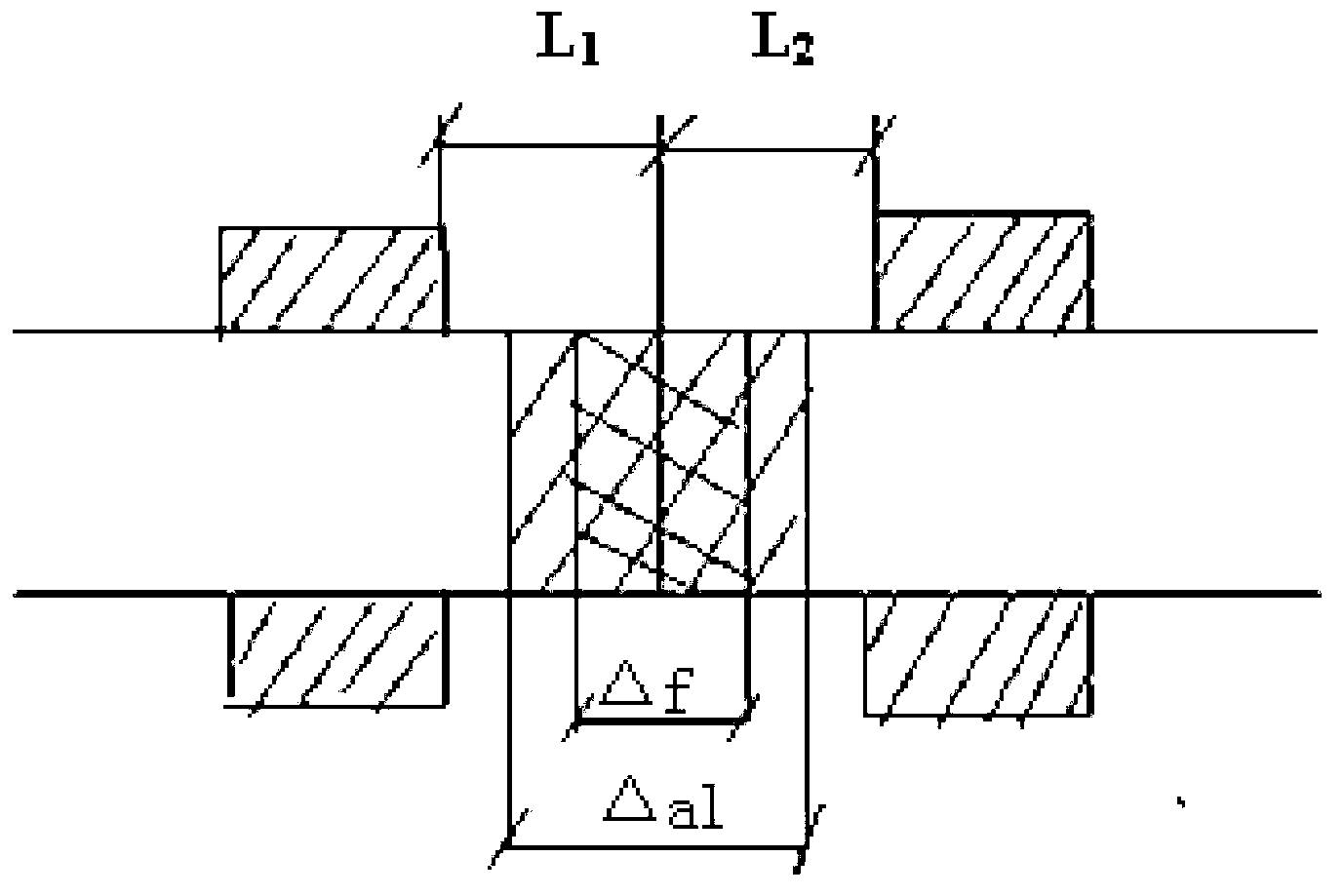

[0027] Then clamp the two ends of the two 4×4mm diamond-shaped tantalum bars with the two electrodes of the butt welding machine respectively, and connect the two electrodes to the transformer of the butt welding machine, so as to generate clamping force above the tantalum bars. The protruding length between the electrodes is L=6mm, the flash margin Δf=1.5mm, and the upsetting margin Δup=4.5mm.

[0028] The preheating of the welding material before welding is carried out on the butt welding machine. After the temperature of the end surface of the weldment is raised to a suitable value through preheating, the flashing and upset forging process is ...

Embodiment 2

[0030] First, cut off the cracked part of the diamond-shaped tantalum bar with a side length of 6×6mm to ensure that the broken end of the tantalum bar is free of cracks, hollows and black centers. Strictly remove oil and other pollutants within 30mm of the welding part, and wipe with alcohol to ensure that the welding area is clean.

[0031] Then two 6×6mm rhombic tantalum strips are respectively clamped by the electrodes, and the two electrodes are connected to the transformer of the butt welding machine, and the clamping force is generated above, and the two ends of the tantalum strips protrude between the two electrodes with a length of L=8mm, flash allowance Δf=1.8mm, upsetting allowance Δup=4.7mm, the welding material is preheated on the welding machine, and the temperature of the end surface of the weldment is raised to a suitable value through preheating, and then Perform flashing and upsetting process. At the end of the preheating phase, the end face of the rod mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com