Connecting device applied between assembly lines

A connecting device and assembly line technology, applied in the field of mechanical devices, can solve problems such as wasting manpower, material resources, and low production efficiency, and achieve the effect of avoiding the consumption of manpower and material resources and optimizing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

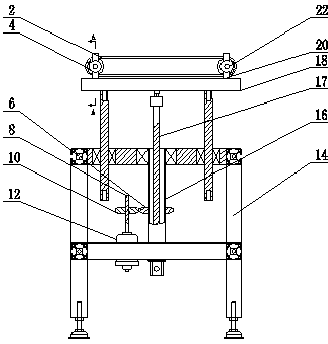

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the present invention is a connection device applied between assembly lines, including a support frame 14, a workbench 18 is arranged above the support frame 14, and the workbench 18 and the support frame are connected by a lifting mechanism for driving the workbench 18 to lift , in the present invention, lifting mechanism comprises the rotating tube 16 of hollow tubular structure, and its outer wall is fixedly connected on the support frame 14 by rolling bearing, and internal thread is provided on its inner wall, and the inside of rotating tube 16 is provided with the elevating rod 17 that protrudes from one end. The extended end of the elevating rod 17 is fixedly connected to the workbench 18, and the elevating rod 17 is also provided with an external thread that cooperates with the internal thread of the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com