Catalytic air flotation device for treatment of sewage

A technology for catalytic gas and sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as inability to remove water-soluble substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

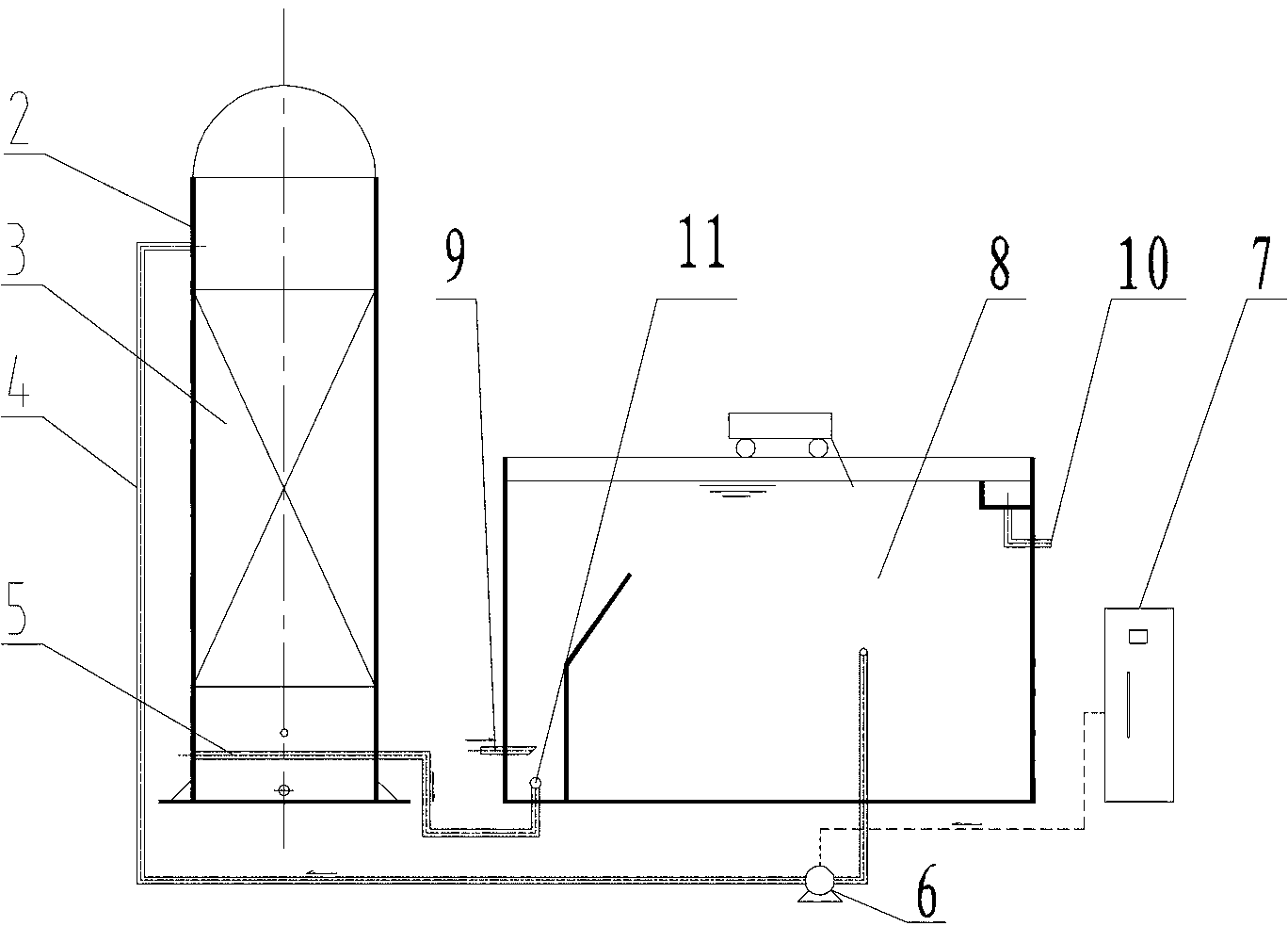

[0008] Specific implementation mode 1: Combination figure 1 To illustrate this embodiment, the device of this embodiment includes a catalytic oxidation reaction vessel 2, a filler 3, a dissolved gas water inlet pipe 4, a dissolved gas water outlet pipe 5, a gas-liquid mixing pump 6, an air floatation machine 8, and an air floatation machine The inlet pipe 9 and the air floatation machine outlet pipe 10, the air floatation tank of the air floatation machine 8 is provided with an air floatation machine inlet pipe 9 and an air floatation machine outlet pipe 10, and the bottom of the air floatation tank of the air floatation machine 8 is connected to the dissolved air inlet pipe 4 One end is connected, and the other end of the dissolved gas water inlet pipe 4 is connected with the upper water inlet of the catalytic oxidation reaction vessel 2. The dissolved gas water inlet pipe 4 is equipped with a gas-liquid mixing pump 6, and the middle of the catalytic oxidation reaction vessel 2 ...

specific Embodiment approach 2

[0009] Specific implementation manner two: combination figure 1 To describe this embodiment, the catalytic oxidation reaction vessel 2 of this embodiment is an ozone-resistant material vessel. The other embodiments are the same as the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 To describe this embodiment, the device of this embodiment further includes an ozone generator 7, and the ozone outlet end of the ozone generator 7 is in communication with the gas-liquid mixing pump 6. The other embodiments are the same as the first embodiment.

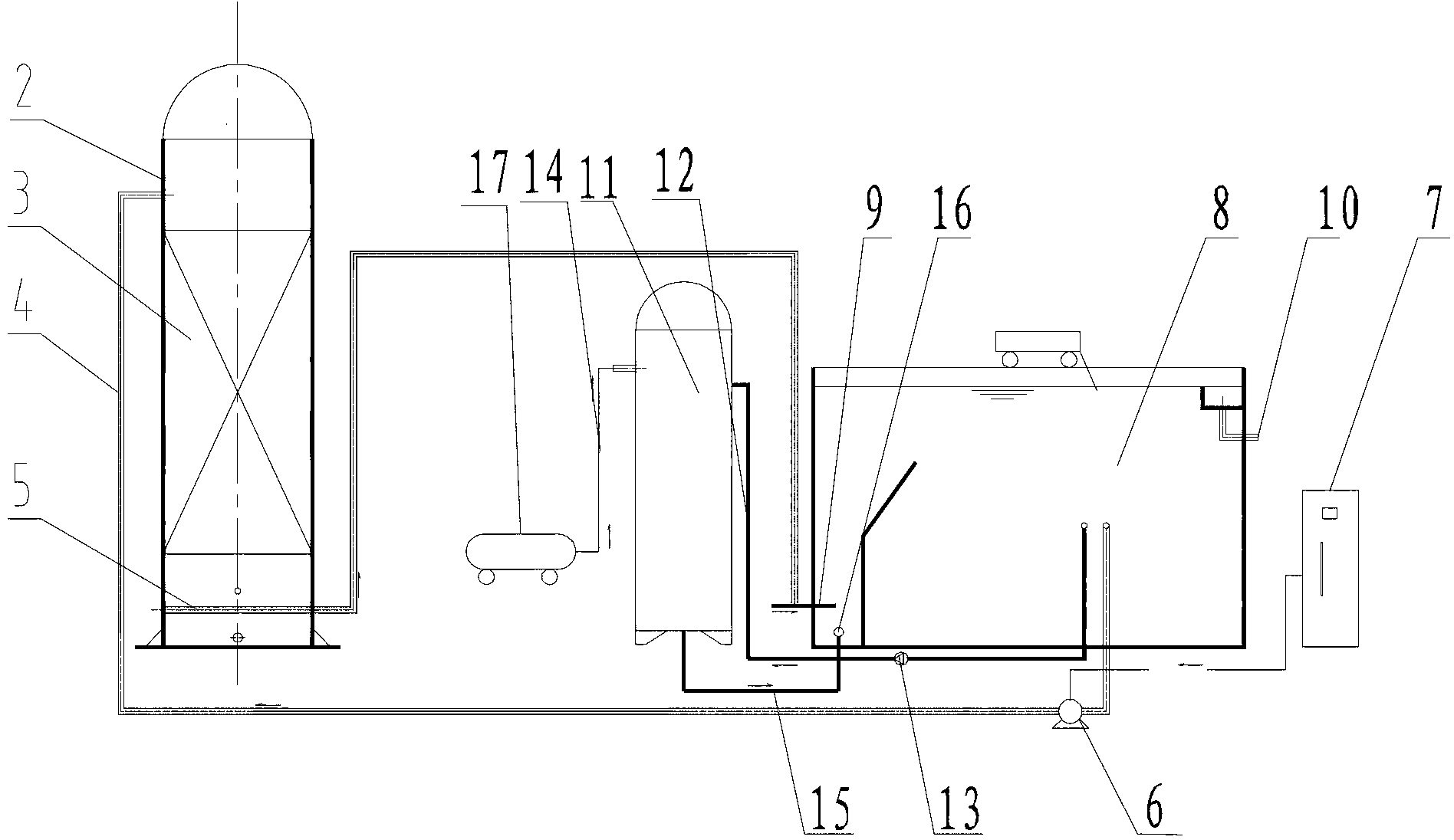

[0011] Specific implementation manner 4: Combination figure 2 To describe this embodiment, the device of this embodiment includes a catalytic oxidation reaction vessel 2, a filler 3, a dissolved gas water inlet pipe 4, a dissolved gas water outlet pipe 5, a gas-liquid mixing pump 6, an air floatation machine 8, and an air floatation machine inlet pipe 9. The air flotation machine outlet pipe 10, the air outlet pipeline 12, the circulating pressure pump 13 and the water outlet pipeline 15. The air floatation machine 8 is connected with the air floatation machine inlet pipe 9 and the air floatation machine outlet pipe 10 respectively, and the air floatation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com