Antibacterial fabric, preparation technology thereof and textile thereof

A technology of antibacterial fabric and preparation technology, which is applied in the field of processing technology and its fabric and antibacterial fabric, can solve the problems of comfort, antibacterial, insecticide, sweat absorption, warmth, single composition, single function, etc. Pulp, good thermal stability, and the effect of improving lung function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

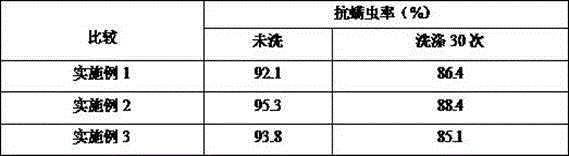

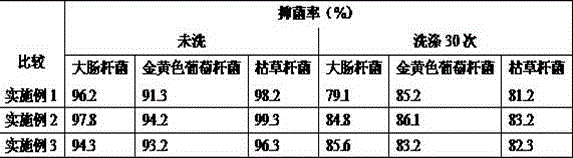

Embodiment 1

[0021] The raw materials according to parts by weight are 10 parts of short fiber silk, 20 parts of anion polypropylene staple fiber, 15 parts of nano bamboo carbon fiber, 2 parts of nano titanium dioxide, 5 parts of nano silver fiber, and 80 parts of polyester cotton fiber at 40 °C, add 2 parts of dispersing Agent, 12 parts of binder, 3 parts of softener, add 100 parts of water, mix and stir evenly, and then air-dry to shape. Among them, the amount of negative ion powder added to the negative ion polypropylene staple fiber is 3%, and the negative ion powder is processed from tourmaline or diatomite, which contains natural ore powder that can release negative ions; the length of the short fiber silk is 1mm; the nanometer titanium dioxide The particle size is 20nm; the length of the nano-bamboo carbon fiber is 200nm; the length of the nano-silver fiber is 30nm. The sweat-absorbing and quick-drying processing agent is composed of water-dispersible polyester, polyurethane, and si...

Embodiment 2

[0025] The raw materials according to parts by weight are 15 parts of short fiber silk, 22 parts of anion polypropylene staple fiber, 20 parts of nano bamboo carbon fiber, 3 parts of nano titanium dioxide, 7 parts of nano silver fiber, 82 parts of polyester cotton fiber at 42 ℃, add 3 parts Dispersant, 15 parts of binder, 4 parts of softener, add 110 parts of water, mix and stir evenly, and then air-dry to form. Among them, the amount of negative ion powder added to the negative ion polypropylene staple fiber is 4%, and the negative ion powder is processed from tourmaline or diatomite, which contains natural ore powder that can release negative ions; the length of the short fiber silk is 2mm; the nano-titanium dioxide The particle size is 60nm; the length of the nano-bamboo carbon fiber is 250nm; the length of the nano-silver fiber is 50nm. The sweat-absorbing and quick-drying processing agent is composed of water-dispersible polyester, polyurethane, and silicone, and the weig...

Embodiment 3

[0029] The raw materials according to parts by weight are 20 parts of short fiber silk, 25 parts of anion polypropylene staple fiber, 25 parts of nano bamboo carbon fiber, 5 parts of nano titanium dioxide, 10 parts of nano silver fiber, 85 parts of polyester cotton fiber at 42 ℃, add 4 parts Dispersant, 18 parts of binder, 5 parts of softener, add 120 parts of water, mix and stir evenly, and then air-dry to form. Among them, the amount of negative ion powder added to the negative ion polypropylene staple fiber is 5%, and the negative ion powder is processed from tourmaline or diatomite, which contains natural ore fine powder that can release negative ions; the length of the short fiber silk is 3mm; the nano-titanium dioxide The particle size is 100nm; the length of the nano-bamboo carbon fiber is 300nm; the length of the nano-silver fiber is 70nm. The sweat-absorbing and quick-drying processing agent is composed of water-dispersible polyester, polyurethane, and silicone, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com