High-sound-insulation fireproof door

A fire door and high partition technology, applied in the field of fire doors, can solve the problems of complex production process, cumbersome installation, waste of steel plate materials, etc., and achieve the effect of simplifying the production process, good fire performance and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

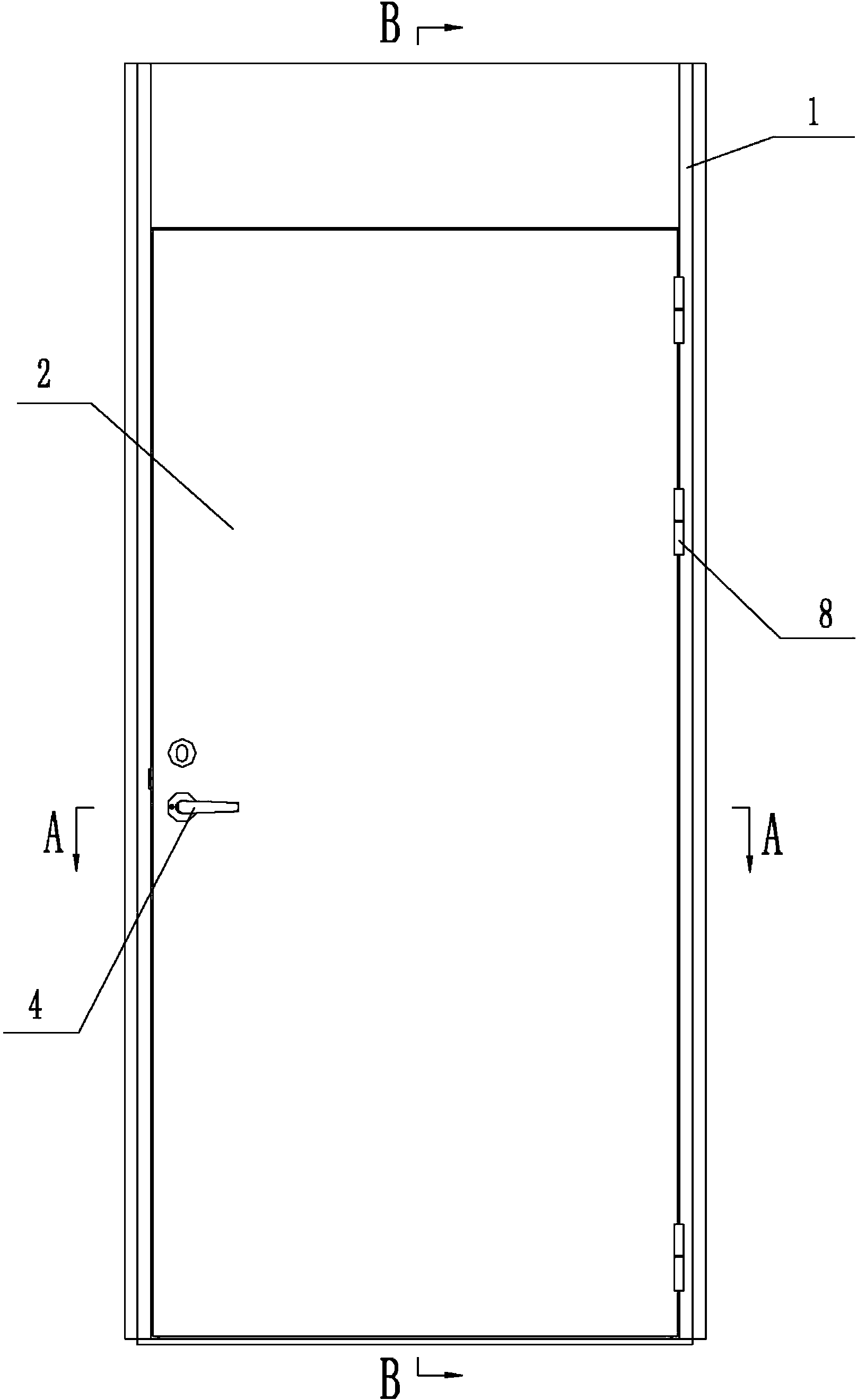

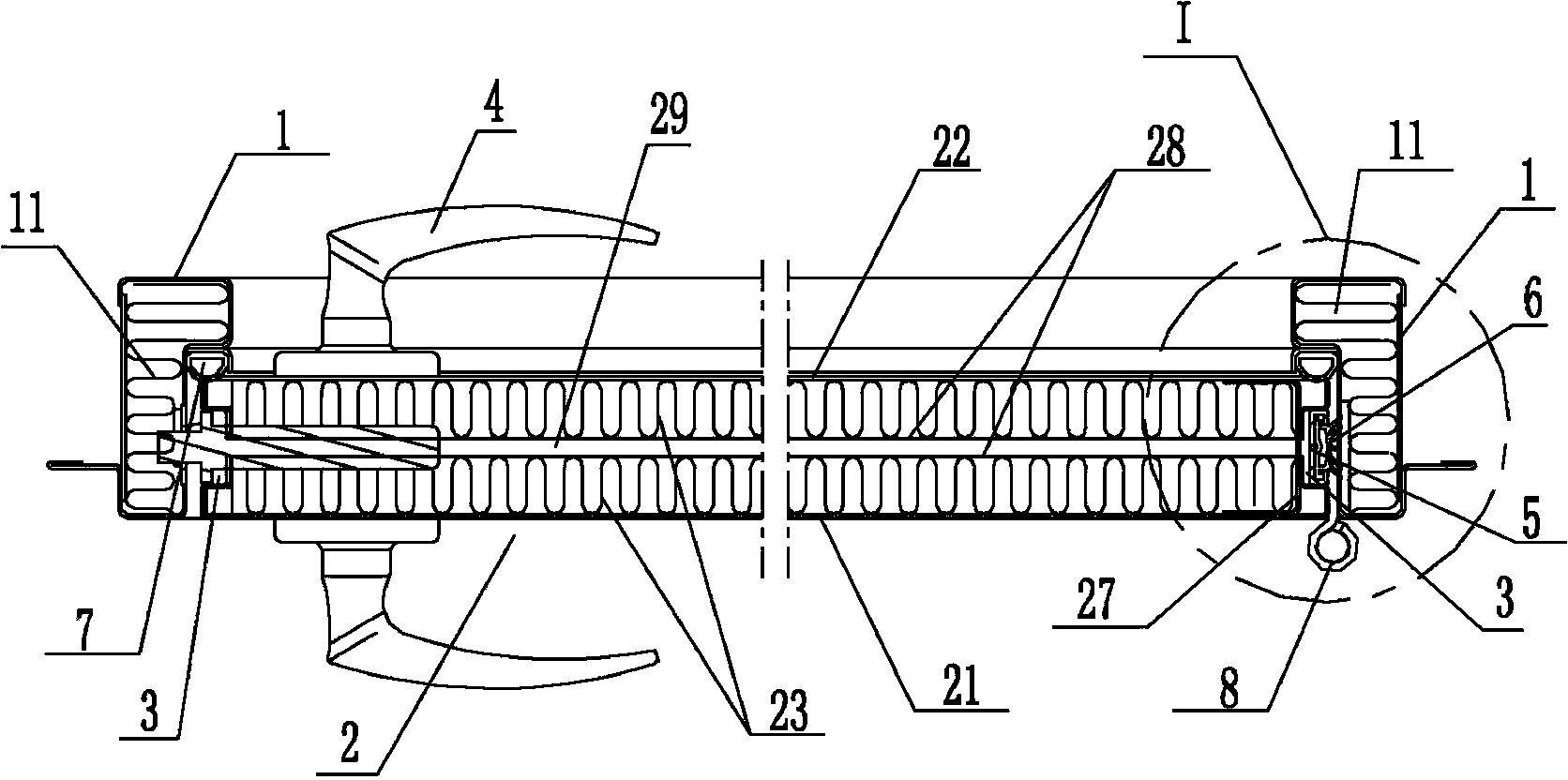

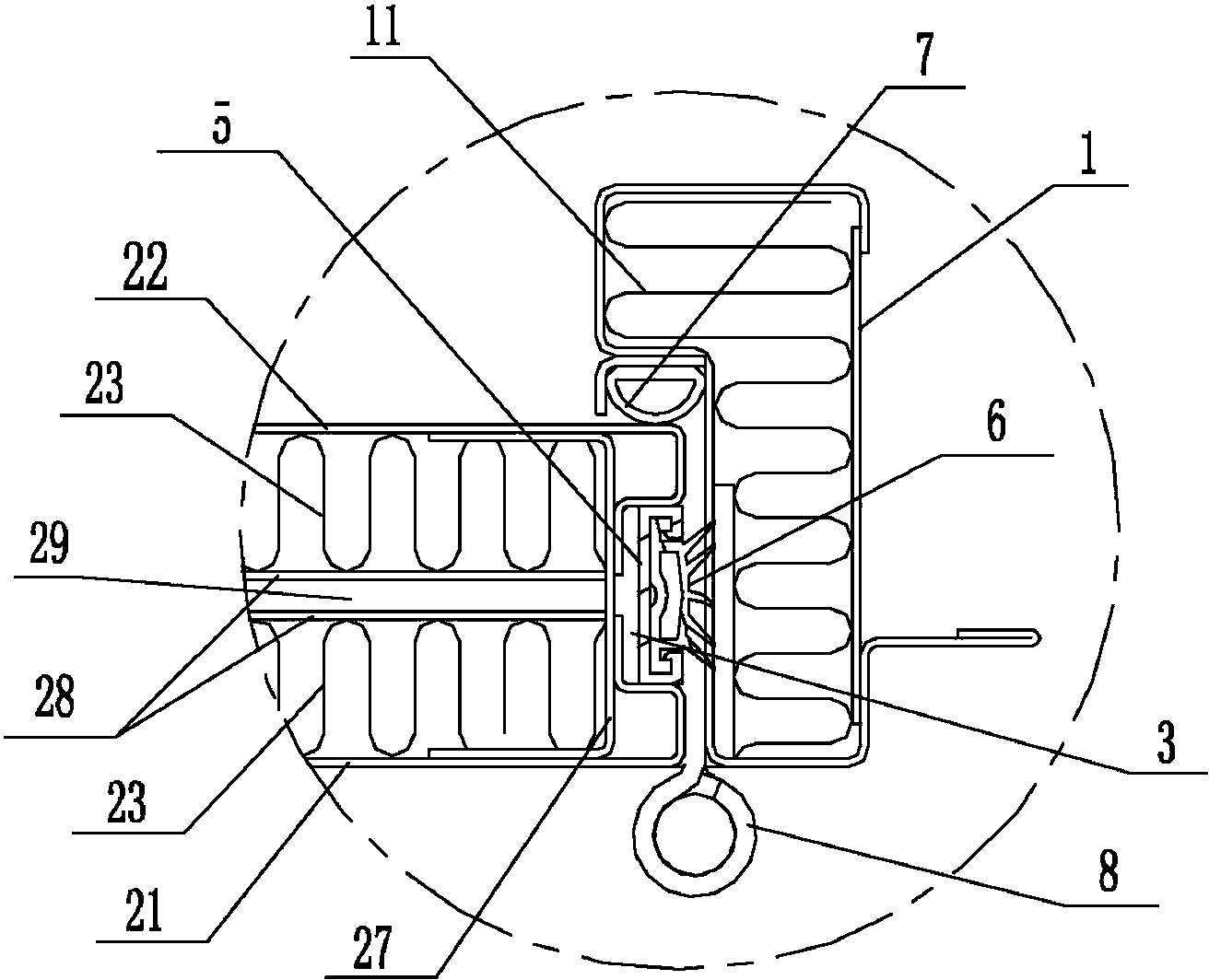

[0021] Such as figure 1 As shown, the high sound insulation fireproof door of the present invention includes a door frame 1 and a door leaf 2, one side of the door leaf 2 is hinged to the door frame 1 through several hinges 8, and a door lock 4 is provided on the other side. Such as figure 2 and Figure 4 As shown, the door leaf 2 further includes: an outer panel 21 , an inner panel 22 , two perforated sound-absorbing panels 28 sandwiched in the interlayer between the outer panel 21 and the inner panel 22 , and a heat-insulating and sound-insulating core material 23 . The heat and sound insulation core material 23 is filled between each punched sound-absorbing panel 28 and its adjacent outer panel 21 or inner panel 22 and is combined with the outer panel 21 or inner panel 22 with an adhesive. An air cavity 29 is formed between the perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com