A flow automatic measurement and control device

A technology of measurement and control device and flow rate, which is applied in the direction of borehole/well valve device, measurement, and production fluid, etc. It can solve the problems of axial thrust bearing damage, valve stem without radial positioning, and low adjustment accuracy, and achieve adjustment accuracy High, improved control accuracy, simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

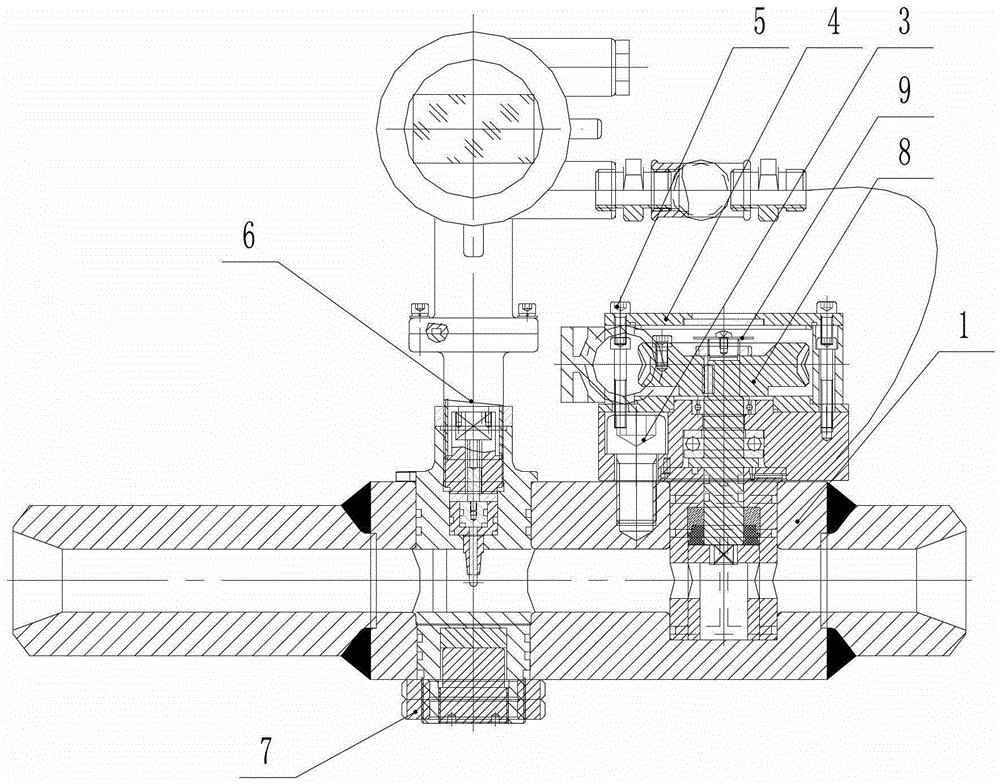

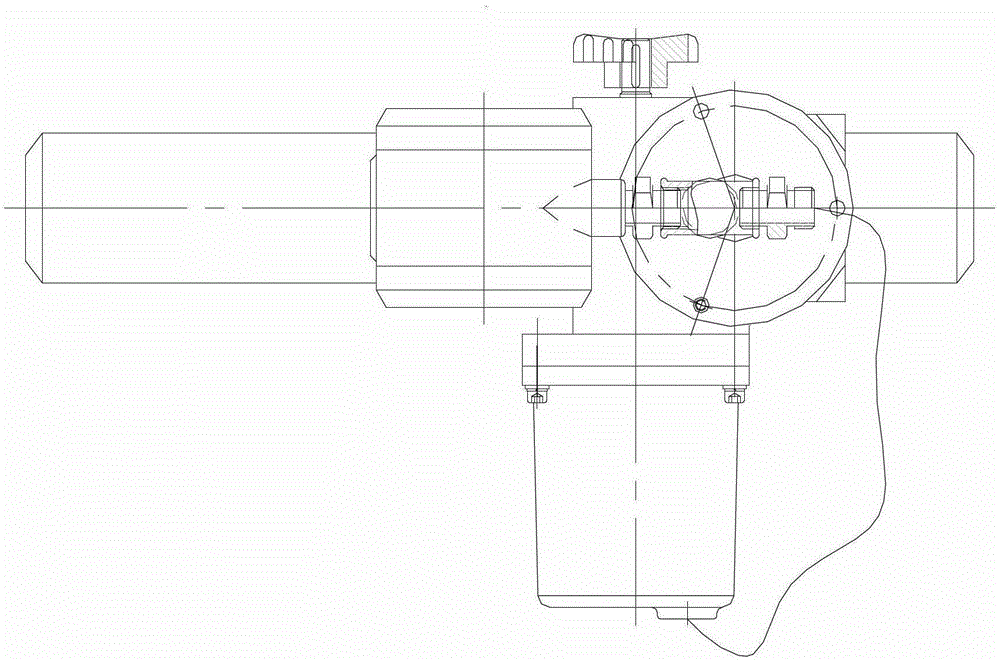

[0027] See figure 1 and figure 2 ,in, figure 1 It is a schematic diagram of the overall structure of the flow automatic measurement and control device of the present invention, figure 2 for figure 1 top view.

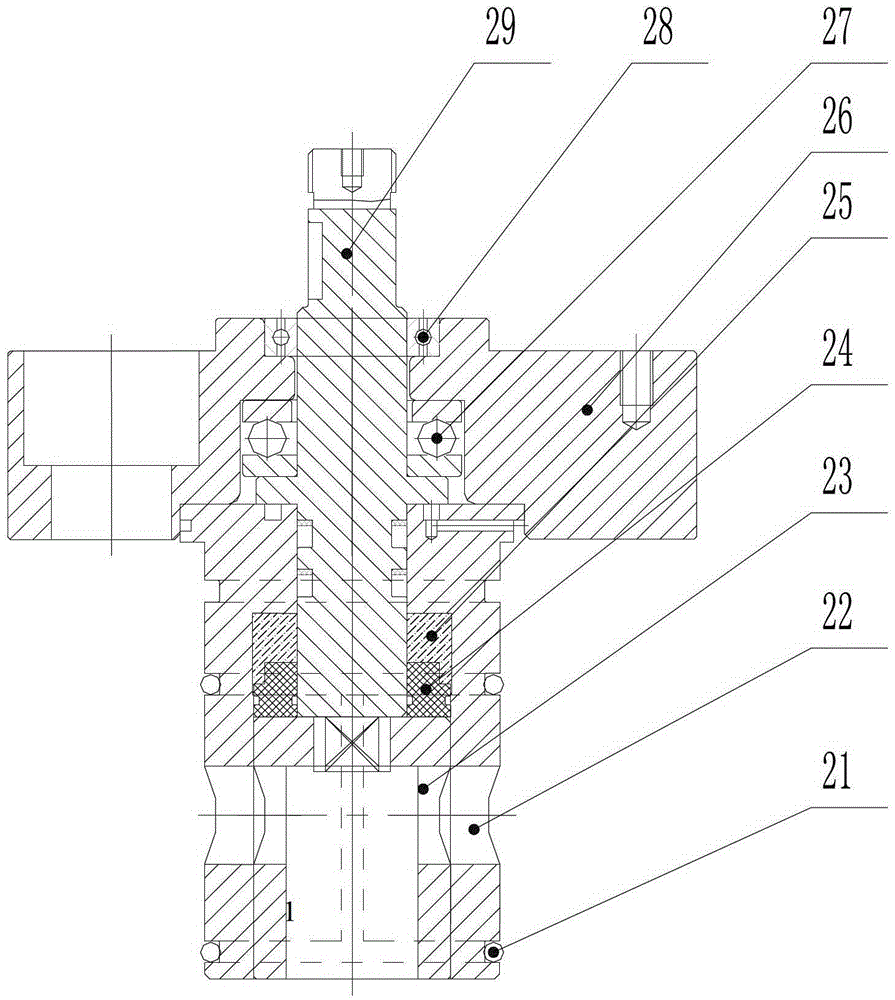

[0028] As shown in the figure, the flow automatic measurement and control device includes a housing 1, a spool assembly, an actuator 8 and a magnetic current meter 6; wherein, the housing 1 has an internal flow channel, and two valves communicating with the internal flow channel The chamber, the shell 1 adopts an integrated structure, the processing error of the flow channel is small, and the measurement accuracy is high; the valve core assembly is arranged in the first chamber to control the flow rate of the internal flow channel through the movement of the valve core 23 to realize opening , closing or opening adjustment; the actuator 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com