Axial plunger pump return-stroke mechanism

An axial plunger pump, return technology, applied in pump components, mechanical equipment, variable capacity pump components, etc., can solve the problems affecting the safe and stable operation of the hydraulic system, the failure of the plunger pump, and the pull-off, so as to avoid empty space. The effect of eliminating cavitation, avoiding the reduction of life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

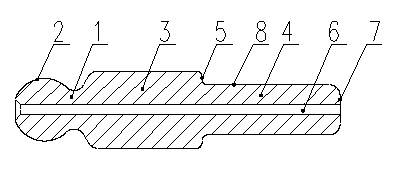

[0023] Such as figure 1 As shown, the plunger 1 of the present invention is stepped, the head 2 of the large-diameter section of the plunger is spherical, the end face 7 of the small-diameter section of the plunger is a plane, and the plunger 1 is provided with an axial through hole 6 .

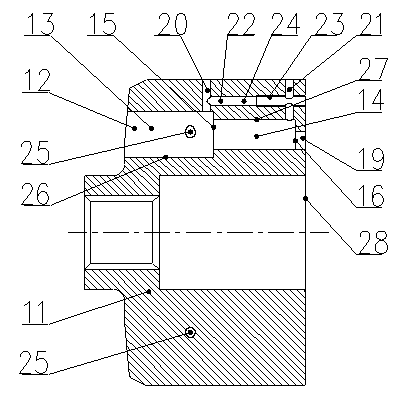

[0024] Such as figure 2 As shown, the wall of the cylinder 11 of the present invention is provided with a plurality of stepped cylinder holes 12 along the axial direction of the cylinder 11 , and each stepped cylinder hole 12 is distributed along the circumferential direction of the cylinder 11 at intervals.

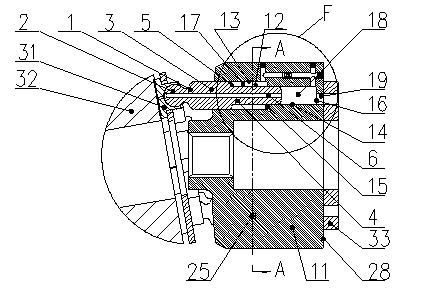

[0025] Such as image 3 , Figure 4 As shown, the plunger 1 is placed in the stepped cylinder hole 12 of the cylinder body 11, the large-diameter section 3 of the plunger forms a clearance fit with the large-diameter section 13 of the stepped cylinder hole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com