Hydrostatic drive system

一种静液压驱动、低压系统的技术,应用在流体压力致动系统组件、流体压力致动装置、遥控马达等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

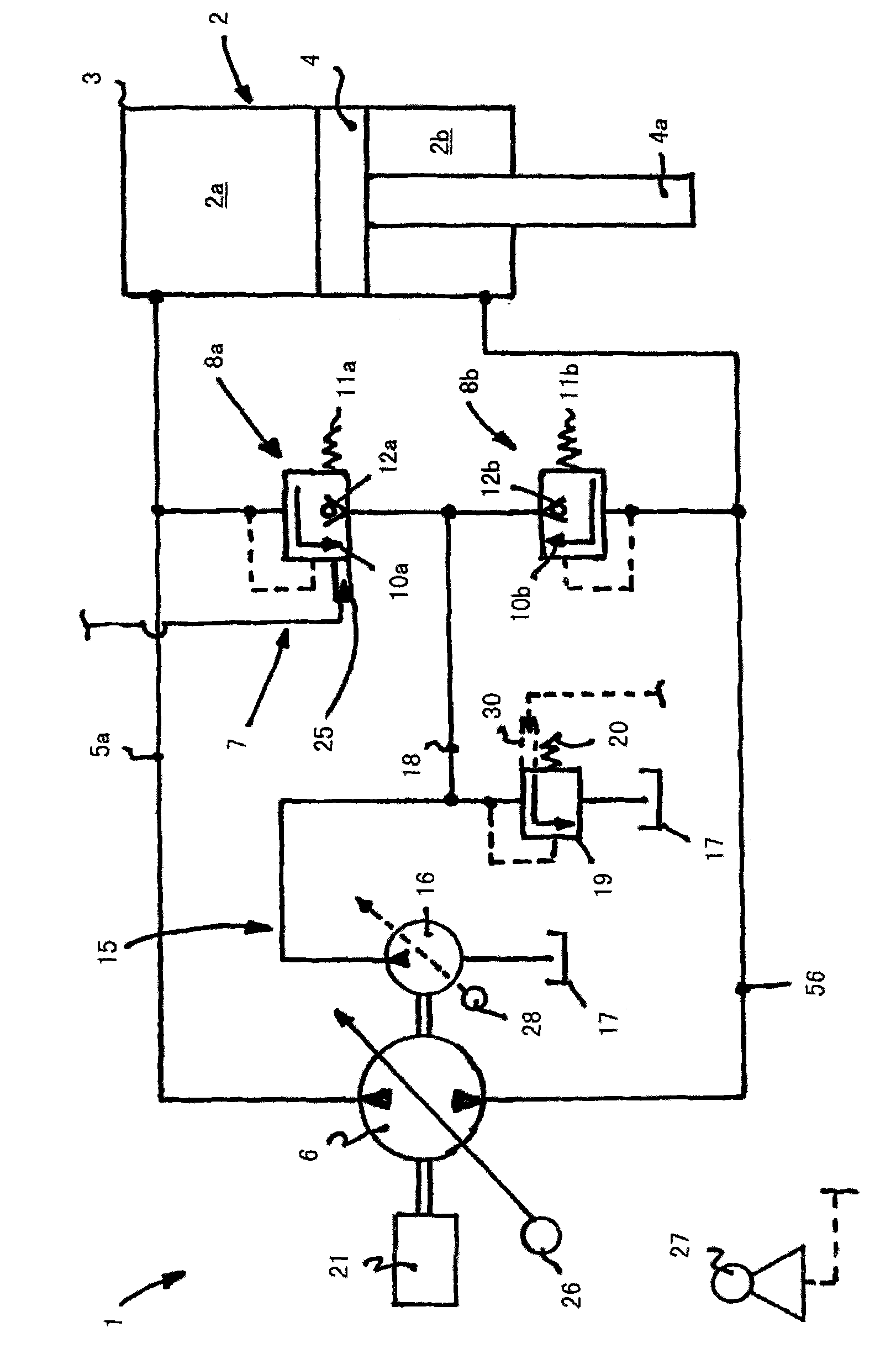

[0019] The drive system 1 comprises a differential hydraulic cylinder 2 operating in a closed circuit as a consumer. The differential hydraulic cylinder 2 comprises a piston which is displaceable longitudinally in a housing 3 and which is provided on one side with a piston rod 4a.

[0020] The differential hydraulic cylinder 2 has a piston-side pressure chamber 2a and a piston-rod-side pressure chamber 2b. The piston-side pressure chamber is connected to the high-pressure pump 6 by means of a first pressure medium pipeline 5a, and the piston-rod-side pressure chamber is connected to a high-pressure pump 6 by means of a second pressure medium. The pipeline 5b is connected with the high-pressure pump 6 . The pressure chambers 2 a , 2 b of the differential cylinder 2 have different volumes depending on the piston rod 4 a arranged in the piston rod-side pressure chamber 2 b.

[0021] The closed circuit formed by the pressure medium lines 5a, 5b and forming a high pressure system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com