Lead-acid storage battery pole plate and preparation method thereof

A lead-acid battery and a manufacturing method technology, which are applied to lead-acid battery electrodes, electrode carriers/current collectors, etc., can solve the problems of sharp corners of a single-piece electrode plate, high consumption of lead alloys, and low paste content, and reduce the The effect of weight, increase in weight-to-weight ratio energy, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

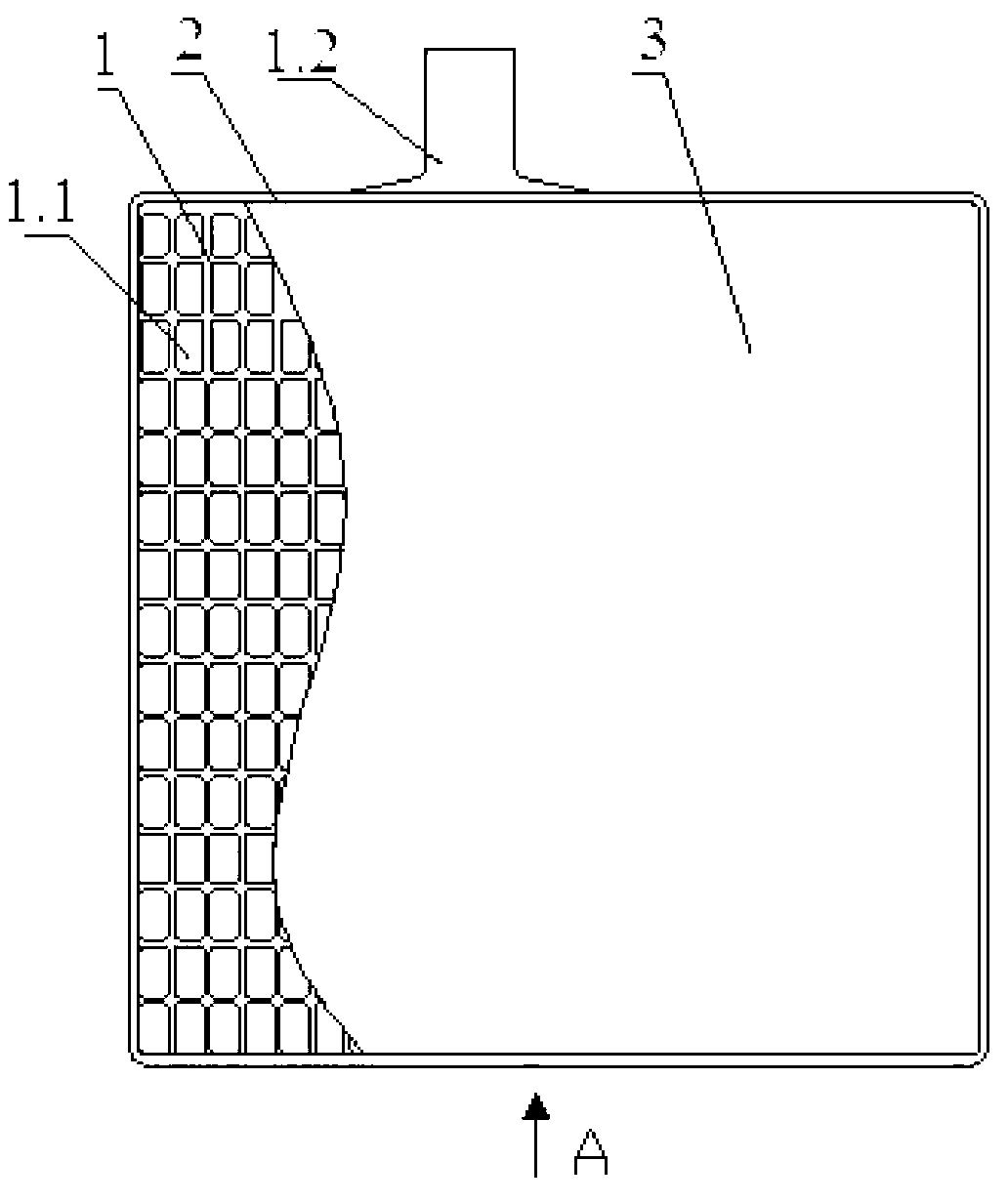

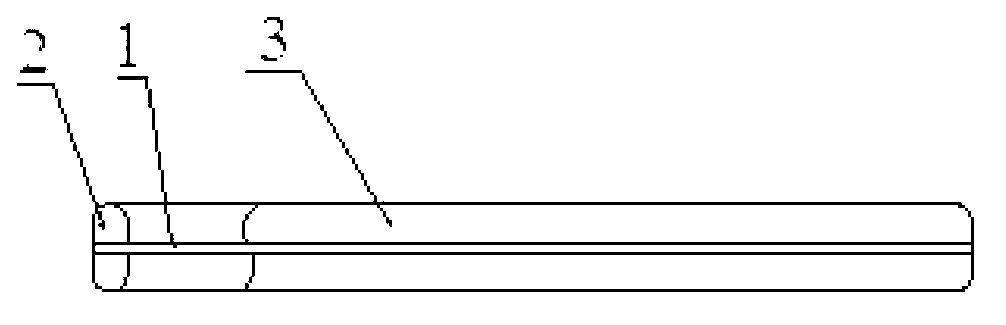

[0017] 1. A lead-acid battery plate: such as figure 1 , figure 2 As shown, it includes a grid and an active material layer 3 coated on the grid, the grid includes a substrate 1, the surface of the substrate 1 is provided with a mesh 1.1, and the edge of the substrate 1 is connected with a plate lug 1.2, The edge of the substrate 1 is provided with a non-conductive frame 2 for limiting the active material layer 3 on the substrate 1, the non-conductive frame 2 protrudes from the substrate 1, and the non-conductive frame 2 is formed by a The upper and lower non-conductive frames are composed of upper and lower non-conductive frames protruding from the upper and lower surfaces of the substrate 1 respectively. The non-conductive fram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com