Direct current polyphase machine

A multi-phase motor, three-phase technology, applied in the shape/style/structure of winding conductors, etc., can solve problems such as the inability of the car to move and the motor to run, and achieve the effect of improving fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

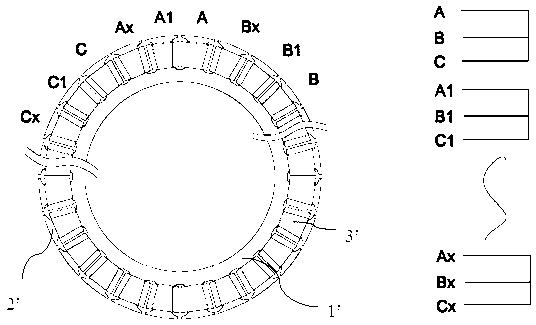

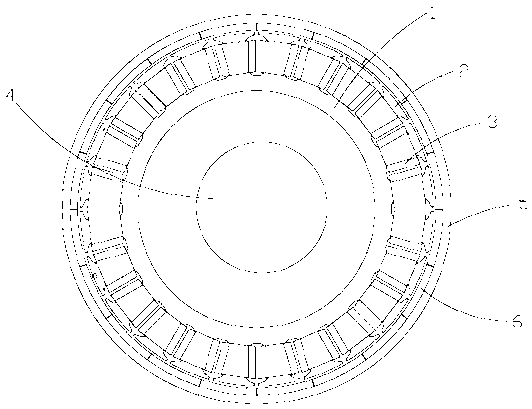

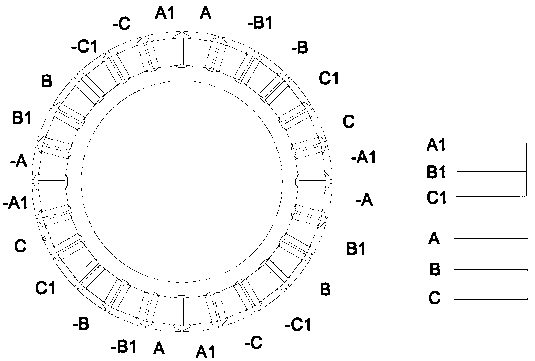

[0022] Such as figure 1 As shown, the DC multi-phase motor of the present invention includes a silicon steel laminated core 1', and a number of slotted teeth 2' are punched on the periphery of the silicon steel laminated core 1', and a coil 3' is wound on each slotted tooth 2'. , B, B1....Bx, A, A1....Ax, C, C1,....Cx are respectively wound on several consecutive groove teeth 2' to form 3(x+1) phase coils 3 ', the above 3 (x+1) phase windings are connected into (x+1) mutually independent three-phase systems, that is, A, B, and C are connected as a three-phase system as an output terminal, and Ax, Bx, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com