Device for directly or indirectly applying a liquid to pasty application medium and method for operating said type of device

A direct, medium technology, applied in the field of material width, can solve problems such as disturbing the environment of air-conditioned rooms, and achieve the effect of reducing overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

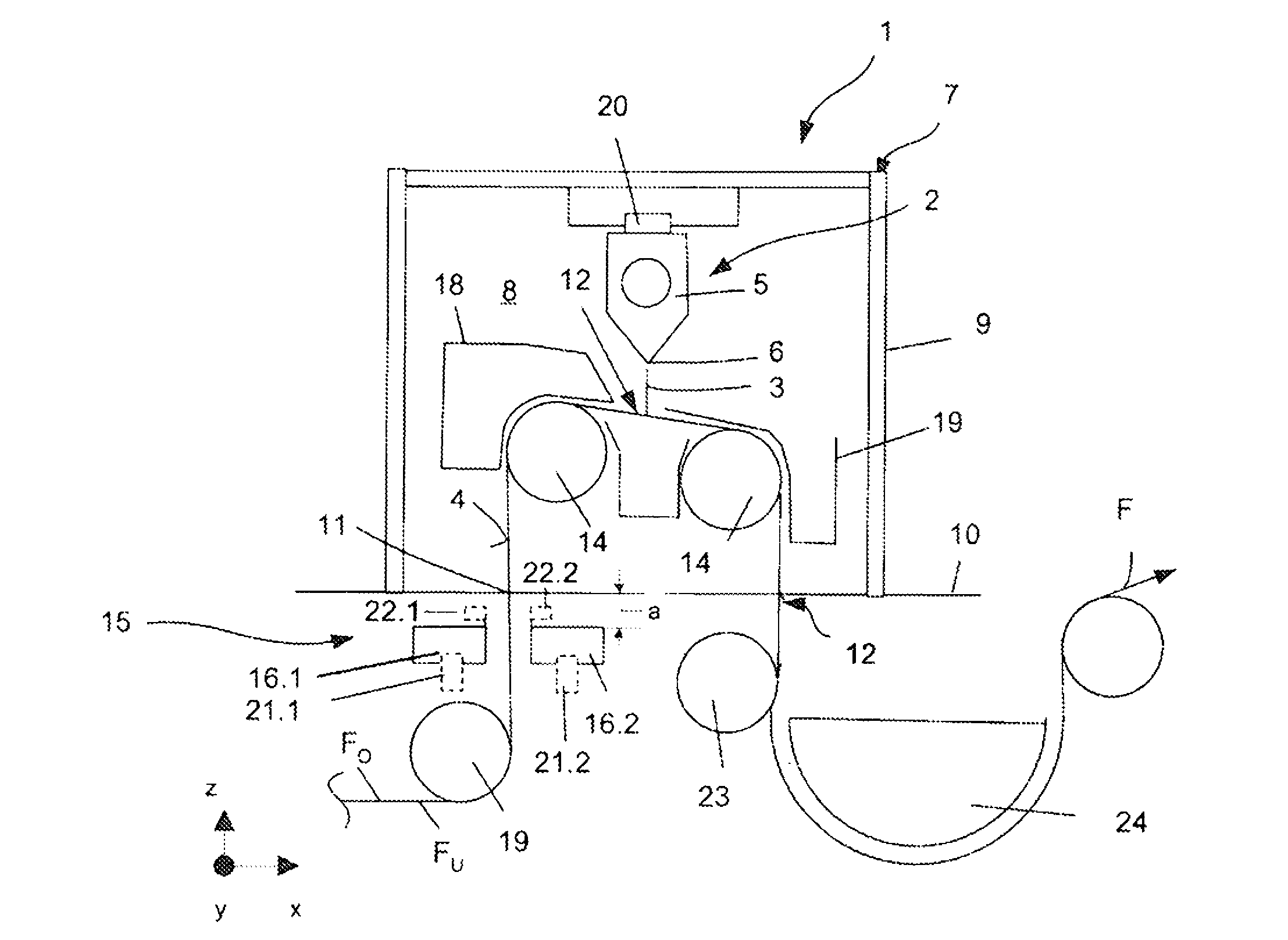

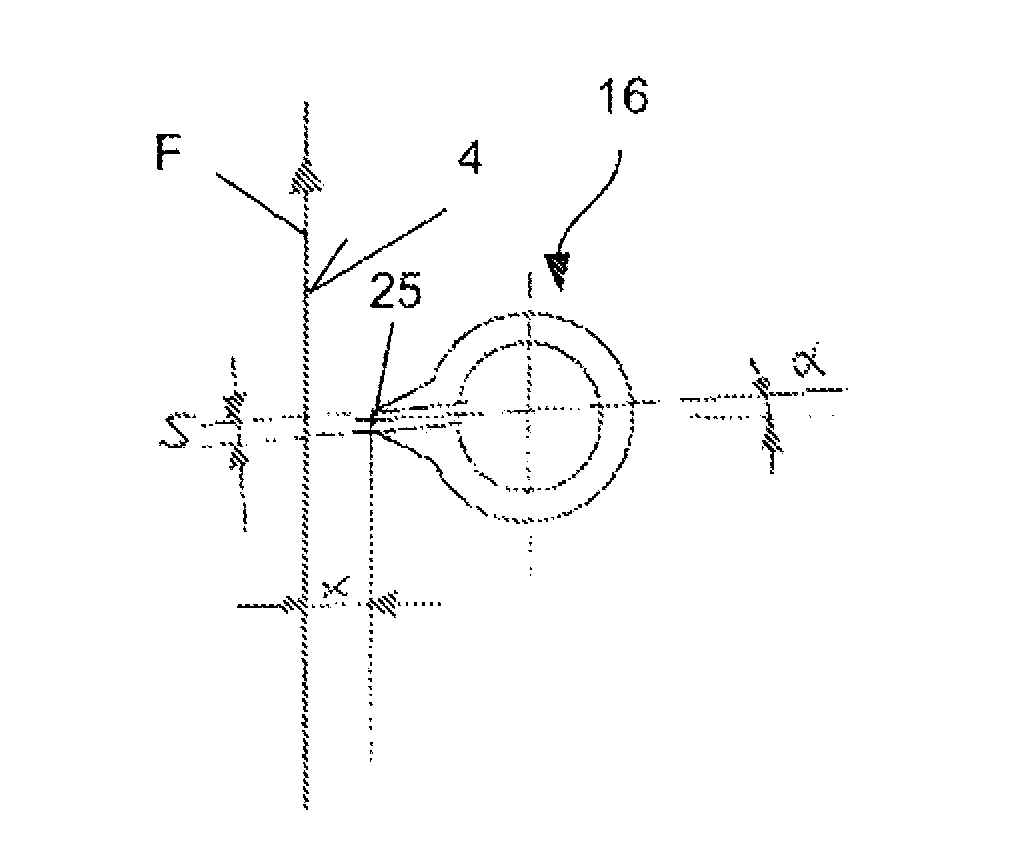

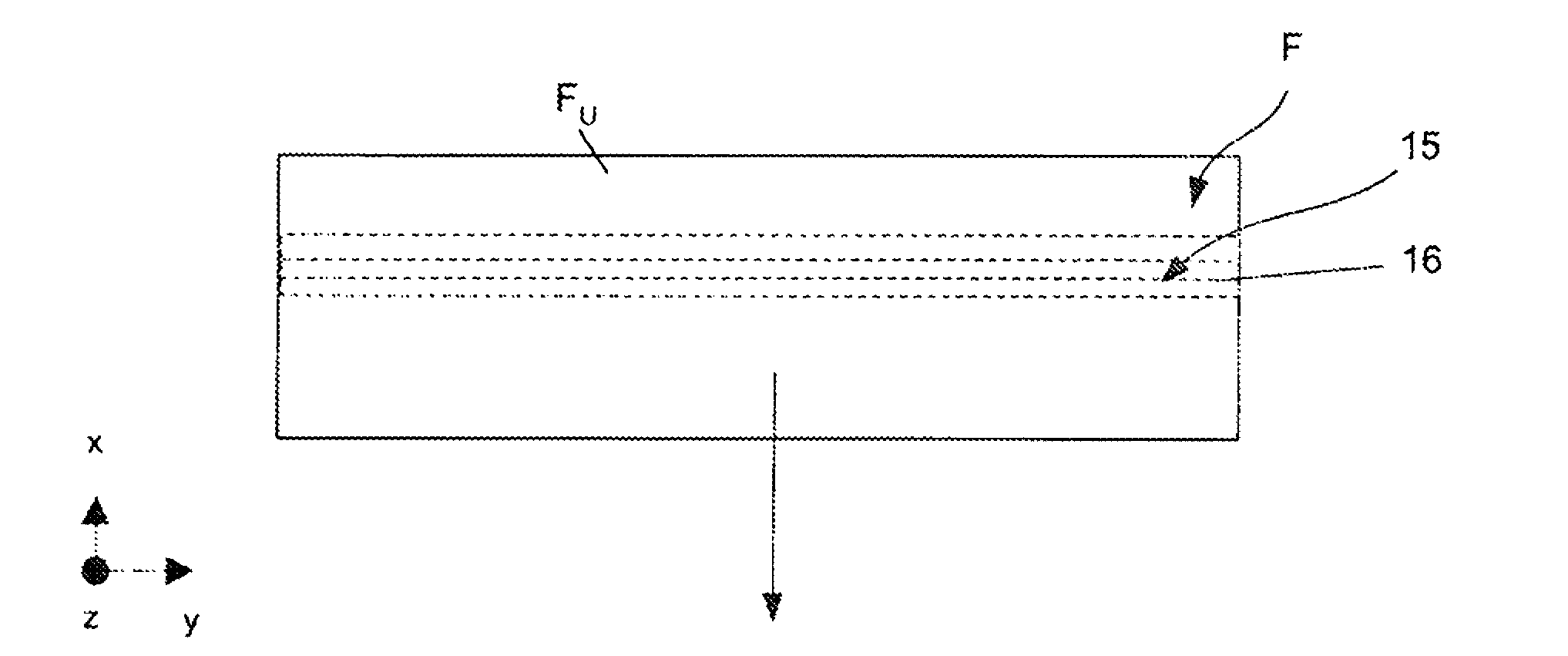

[0043] figure 1 The basic structure of a device 1 designed according to the invention for applying a liquid to pasty coating medium onto a material web in the form of a moving fibrous web F is shown schematically. In order to illustrate the individual directions, a coordinate system is set up on the device by way of example. The X direction describes the longitudinal direction of the device, which coincides with the direction of travel of the material web F through the device 1 . The Y direction describes the width direction, ie the direction transverse to the direction of travel of the fibrous web F. The Z direction represents a height direction.

[0044] The device 1 is represented here as a separate, ie independent device. The plant can either be directly downstream of the plant for producing the fibrous web F as an in-line plant, wherein the fibrous web F is then led directly out of the machine for producing the fibrous web into the plant 1 . If the plant 1 is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com