Erythritol and sucralose cocrystal product and cocrystallization method thereof

A technology of erythritol and sucralose, which is applied in the field of co-crystallization, can solve the problems of unstable product composition, difficult control of proportioning ratio, poor repeatability, etc., and achieve good mouth-melt feeling, low production cost and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

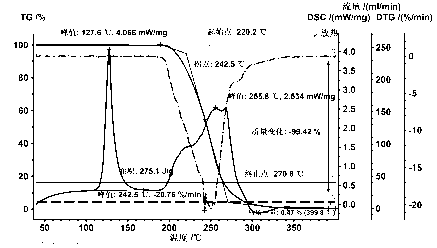

Embodiment 1

[0055] A co-crystal product of erythritol and sucralose and a co-crystal method thereof, the specific steps are:

[0056] Step 1, heating the raw material erythritol crystals to 120-135°C to obtain a clarified erythritol melt;

[0057] Step 2. Mix sucralose accounting for 1-5wt% of the raw material erythritol with water accounting for 10-20wt% of the raw material erythritol to prepare a suspension; 100°C, completely dissolve the sucralose to obtain a clear aqueous solution of sucralose;

[0058] Step 3. Stir the erythritol melt solution obtained in step 1 at 120~135°C and a rotational speed of 150~350r / min, and add the aqueous sucralose solution obtained in step 2 while stirring to obtain a clear co-crystal Mother liquor; then under the condition of 150~350r / min, cool the co-crystal mother liquor to 100~120℃, add the seed crystal while stirring, the particle size of the seed crystal is 40~200 mesh, the amount of seed crystal added accounts Thyritol 1-15wt%, stirring at const...

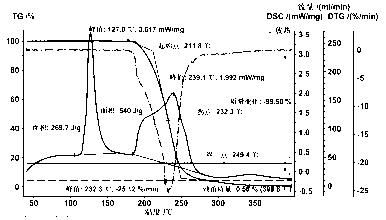

Embodiment 2

[0064] A co-crystal product of erythritol and sucralose and a co-crystal method thereof, the specific steps are:

[0065] Step 1, heating the raw material erythritol crystals to 120-135°C to obtain a clarified erythritol melt;

[0066] Step 2. Mix sucralose accounting for 5-10 wt% of the raw material erythritol with water accounting for 10-20 wt% of the raw material erythritol to prepare a suspension; 100°C, completely dissolve the sucralose to obtain a clear aqueous solution of sucralose;

[0067] Step 3. Stir the erythritol melt solution obtained in step 1 at 120~135°C and a rotational speed of 150~350r / min, and add the aqueous sucralose solution obtained in step 2 while stirring to obtain a clear co-crystal Mother liquor; then under the condition of 150~350r / min, cool the co-crystal mother liquor to 100~120℃, add the seed crystal while stirring, the particle size of the seed crystal is 40~200 mesh, the amount of seed crystal added accounts Thyritol 1-15wt%, constant tempe...

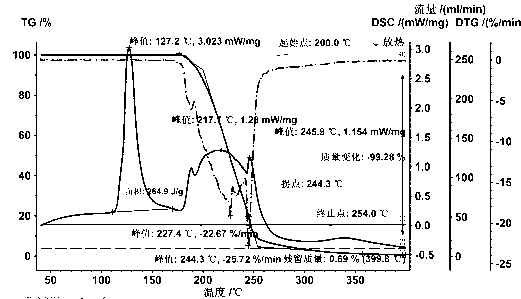

Embodiment 3

[0073] A co-crystal product of erythritol and sucralose and a co-crystal method thereof, the specific steps are:

[0074] Step 1, heating the raw material erythritol crystals to 120-135°C to obtain a clarified erythritol melt;

[0075] Step 2. Mix sucralose accounting for 10-15wt% of the raw material erythritol with water accounting for 10-20wt% of the raw material erythritol to prepare a suspension; 100°C, completely dissolve the sucralose to obtain a clear aqueous solution of sucralose;

[0076]Step 3. Stir the erythritol melt solution obtained in step 1 at 120~135°C and a rotational speed of 150~350r / min, and add the aqueous sucralose solution obtained in step 2 while stirring to obtain a clear co-crystal Mother liquor; then under the condition of 150~350r / min, cool the co-crystal mother liquor to 100~120℃, add the seed crystal while stirring, the particle size of the seed crystal is 40~200 mesh, the amount of seed crystal added accounts Thyritol 1-15wt%, stirring at cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap