Wheel assembly production line

A production line and wheel technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency of wheel assembly assembly, hidden dangers, safety of wheel assemblies, etc., to protect safety, improve work efficiency, The effect of saving workshop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

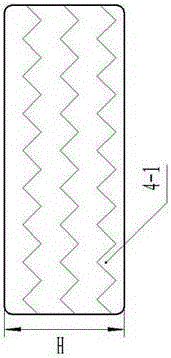

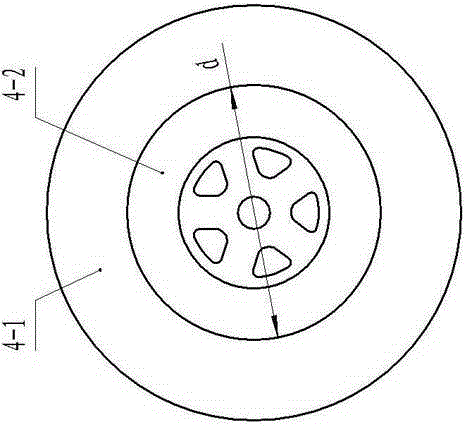

[0015] Such as figure 1 and figure 2 Shown wheel assembly 4, wheel assembly 4 comprises tire 4-1 and the wheel 4-2 that is contained in tire 4-1 wheel, and the diameter d of wheel 4-2 is 815 millimeters, and height H is 600 millimeters; Tire 4 -1 has a diameter D of 1800 mm.

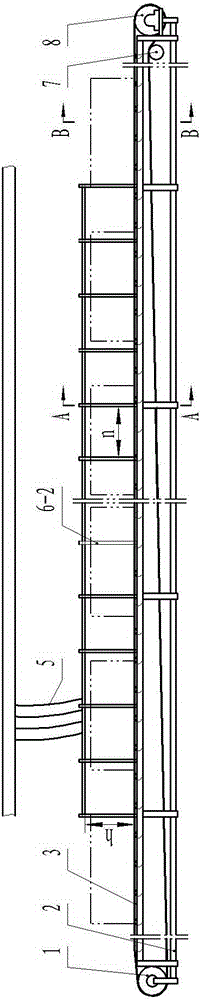

[0016] Such as image 3 , 4 , 5 and Figure 6 The shown wheel assembly production line comprises a driving wheel 8 and a driven wheel 1 installed at both ends of the frame 2, a conveyor belt 3 is installed between the driving wheel 8 and the driven wheel 1, and a conveyor belt 3 is installed between the driving wheel 8 and the driven wheel 1. Tension pulley 7 is installed on the frame 2 of conveyer belt 3 bottoms, step plate 10 is equipped with in the both sides of conveyer belt 3, driving wheel 8 is connected with power machine, and the power machine of present embodiment is electric motor 9; Conveyor belt 3 is rubber band. The frame 2 in the middle part of the conveyor belt 3 is equipped with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com